Pressure gauges will enable the operator to monitor the

pump performance and determine whether the pump

conforms to the parameters of the performance curve

If cavitation, vapor binding, or other unstable operating

situations occur, the pressure gauges will indicate with

wide fluctuation in the inlet and outlet pressures.

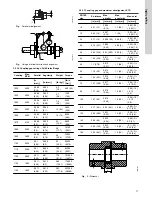

3.5.1.4 Outlet pipe

•

A short outlet pipe can be the same diameter as the pump

outlet port. A long outlet pipe must be one or two sizes larger

than the outlet port, depending on the length.

•

It is best to use long horizontal outlet pipes.

•

Install a non-return valve to protect the pump from backflow

and excessive backpressure. The check valve should be

installed between the isolation valve and pump.

Pump backspin and hydraulic shock can cause severe

damage to the pump and driver.

•

Install a gate valve near the outlet port to be able to isolate the

pump during shutdown and maintenance, and to facilitate

pump removal.

•

Any high points in the outlet pipe may entrap air or gas and

thus reduce pump operation.

Operating pumps against a closed valve will cause an

increase in pressure and power.

If an increaser is used on the outlet pipe to increase the

pipe size then it should be placed between the non-return

valve and the pump. If expansion joints are used then

they should be placed between the pipe support or anchor

and the non-return valve.

3.5.1.5 Nozzle load

The pipes should be aligned with the pump nozzles to minimize

pump nozzle loads. Refer to ANSI/HI 9.6.2 for assessment of

applied nozzle loads.

3.5.2 Impeller clearance

To achieve optimal performance and service life, the impeller

clearance must be centered in the volute. Pumps are shipped from

the factory with the impeller clearance set.

3.5.3 Alignment

Misalignment of the pump and driver can cause product

failure.

Reliable, trouble-free, and efficient operation requires accurate

alignment of pumps and drivers mounted on a common base plate.

Shipping and installation can alter the factory alignment. Therefore,

check the alignment after:

•

mounting.

•

the grout has hardened.

•

the foundation bolts are tightened or adjusted.

•

the pipes to the product are connected.

•

pump, driver or base plate is moved.

To check alignment, mount a dial indicator to measure shaft

movement before and after tightening the flange bolts.

To facilitate accurate field alignment, we do not dowel the

pumps or drivers on the base plates before shipment.

If the product does not stay in alignment after installation, possible

causes of misalignment are:

•

setting, seasoning or springing of the foundation.

•

excessive force on the pipes distorting or shifting the machine.

•

settling of the building.

•

shifting of pump or driver on the base plate or foundation.

Misalignment may be the cause of:

•

noisy pump operation

•

vibration

•

premature bearing failure

•

excessive coupling wear.

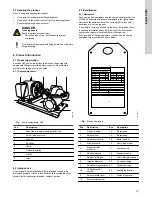

3.5.3.1 Checking the alignment

The procedure for verifying the alignment of a pump and driver

connected by a flexible coupling, mounted on a common base plate

are:

1.

Disconnect the coupling halves.

2.

Set the coupling gap to the recommended alignment

dimension.

3.

Test for parallel and angular alignment with a straight edge and

feeler gauge.

4.

An alternate test for parallel and angular alignment may

be made as follows with a dial indicator mounted:

• Scribe the index lines on the coupling halves or set the

indicator dial to zero.

• Slowly turn both coupling halves so that the index lines

match.

• Observe the dial reading to determine whether pump or

driver

• Acceptable parallel and angular alignment occur when total

indicator reading (complete turn) does not exceed limits

shown on either a tag or decal on the unit or on the unit

outline drawing.

5.

When a significant operating temperature differential exists

between the pump and driver (i.e. a steam turbine driver

with a pump handling cold liquid), thermal growth causes the

hotter component to rise. You can compensate for this by

initially setting the hotter unit 0.003 to 0.005 in. (0.076 to 0.127

mm) lower. When both units are at normal operating

temperature, make a final check and correct the alignment if

necessary.

Check for correct electric motor rotation while

coupling halves are disconnected.

6.

Correct for excessive parallel and angular misalignment by

slightly shifting the leveling wedges under the base plate. Tap

lightly (in or out) with a hammer. Retest alignment each time

after you shift a wedge.

7.

It may be necessary to change the shims under the pump or

driver or even relocate the pump or driver on the base plate.

Make such changes only after you are sure that shifting the

wedges do not achieve alignment.

8.

If wedges are shifted or shims are shifted, recheck the pipe

alignment and the level of the shafts.

X

Y

TM060221

Fig.

Angular misalignment

10

English (US)