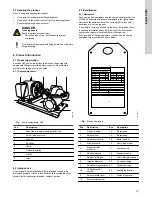

8. Servicing the product

8.1 Maintenance

WARNING

Electric shock

Death or serious personal injury

‐

Switch off the power supply before you start any work

on the product.

WARNING

Overhead load

Death or serious personal injury

‐

Do not attempt to lift the system or pump by the lifting

lugs or eyes of the driver or pump.

‐

No point loads must occur.

‐

Do not work under a suspended system or pump.

8.2 Maintenance schedule

To ensure satisfactory operation of the pumping equipment,

frequent inspection and periodic maintenance are required.

An inspection and maintenance log should be kept, and the

inspector must report any problems immediately. A suggested guide

for preventative maintenance for normal applications is given below.

Unusual applications with abnormal heat, moisture, dust, etc., may

require more frequent inspection and service.

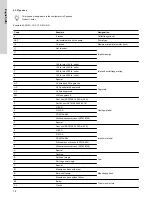

Item

Action

Frequency

Packing,

packing box

Inspect for

excessive

leakage

First 150 hours of

operation, then

every 2000 hours of

operation or

quarterly

Packing,

packing box

Adjust gland and

replace packing

As necessary

Pump-motor

alignment

Check for change in

alignment

Frequently (at every

start and stop)

Vibration

Check for change in

vibration

Annually

Bearings

Lubricate (grease)

• Light Duty, approx.

10 hours/week

• Every 2000 hours

or at least once a

year

• Normal Duty,

approx. 8 hours/day

• Every 2000 hours

or at least every six

months

• Severe Duty,

approx. 24

hours/day

• Monthly

Fasteners

Check for loose

fasteners

Annually

8.2.1 Lubricant and sealant properties

For sealing low-pressure flange joints and similar applications, use

a product similar to Loctite® 515.

Lubricants with the properties mentioned in the tables below must

be selected for lubrication in standard applications.

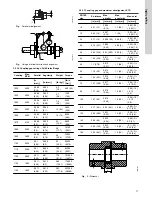

Compon

ents

Maximu

m RPM

Ambient

operating

temperat

ure

NLGI

grade

Kinemati

c

viscosity,

ASTM D

445

Food

grade

Shaft

bearings

3600

-10 to

+250 °F

(-23 to

121 °C)

2

160 cST,

[104 °F (

40 °C)]

H-1

Inlet

manifold

bearings

Stuffing

box

packing

8.2.2 Recommended spare parts

The list of recommended spare parts will depend on factors such

as:

supplier lead times, if the pump is used for normal or severe duty

operation, and if a backup pump is available for use.

A suggested list of spare parts for intermittent or no-critical

operation:

•

stuffing box packing (13)

•

ball bearing set (16 & 18)

•

bearing seal set (47 & 169)

•

bearing cover gaskets (73B)

•

set of shaft sleeves (14 & 14A)

•

set of sleeve O-rings (14B)

•

set of volute rings (7)

•

set of impeller rings, if supplied (8)

•

Volute gasket (73A)

•

packing gland

•

studs and gland bolts.

In addition to the above list, a suggested spare part for continuous

or critical operation:

•

complete rotating element, preassembled.

8.2.3 Consumables

The following items are normally used in the maintenance of

pumping equipment:

•

lubricant (grease or oil)

•

cleaning materials

•

touch-up coating

•

hand tools

•

measuring equipment (feeler gauges, dial indicator, etc.).

Some items may vary depending on the type of unit.

18

English (US)