11 / 14

-

Carry out 2÷3 pump start-ups and check that the settings are correct.

At any rate, in order to ensure maximum efficiency, regular controls on the panel operation and on the

values set are suggested.

To restore panel operation after the overload protection operation, remove the cause of malfunctioning

and press the RESET button on the front board.

8 – TECHNICAL FEATURES OF THE SELF-POWERED PANEL WITH HORN AND FLASHING LIGHT

(optional)

-

230 V ± 10% - 50/60Hz single-stage power supply;

-

IP55 thermoplastic material shell

-

Control input from N/O clean contact

-

Control input from N/C clean contact

-

Green ‘NETWORK PRESENCE’ indicator light LED

-

Red ‘ALARM’ indicator light LED

-

Red ‘EXCLUDED HORN’ indicator light LED

-

‘TEST’ button for temporary activation of the horn and flashing light

-

‘RESET’ button for manual turn-off of the horn and flashing light

-

‘HORN EXCLUSION’ button for the exclusion of the buzzer and flashing light

-

‘HORN ACTIVATION’ button to activate the buzz and flashing light

-

Selector to set the alarm reset mode (automatic – manual)

-

Selector for the activation of the automatic horn turn-off timer

-

Trimmer for calibration of the automatic horn turn-off timer

-

Protection fuse for the card power supply

-

Battery protection fuse

-

12V DC - 90dB buzzer

-

12V DC - 3W red flashing light

-

12V DC - 1.2Ah internal buffer battery

-

Output with clean contacts in N/O – C – N/C exchange 250V – 10A

9 – INSTALLATION AND ACTIVATION OF THE ALARM PANEL

6.

Fix the panel to a wall by means of appropriate screws and dowels, using the ports on the box;

the panel must be installed in a closed, ventilated environment, in which there are no dust,

acids, corrosive and/or inflammable gases. The room temperature must be b4°C and

+40°C.

7.

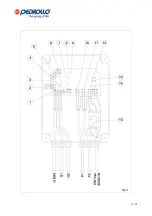

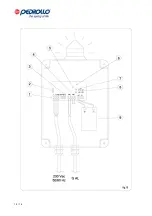

Set up the electrical connections as shown in the diagram in Fig. B, making sure that the power

supply voltage is appropriate for the panel (230V±10% 50/60Hz).

8.

Connect the faston to the positive pole of the buffer battery

9.

Remove any plastic or metal impurity (e.g. copper fragments from the cables, plastic slivers, dust,

etc.) inside the box and power the panel. On the front board the green ‘LIVE’ LED switches on;

in this condition the internal buffer battery is automatically kept on charge so that it is always

efficient.

10.

Check the correct operation of the panel by pushing the ‘TEST’ button on the front board.

When one of the two N/O or N/C inputs (4) changes status (i.e. when the N/O contact is closed or the

N/C contact is opened) the alarm is triggered.

The N/O contact is connected to the alarm float that must be located inside the reservoir, while the N/C

contact is kept closed by a bond.

It is possible to set the panel so that the alarm signal turns off automatically when the condition that

triggered the alarm ceases to exist (e.g. when the N/O and N/C inputs go back to normal) or it remains

on even if the alarm condition no longer exists.

In the latter case the turn off may be carried out manually pushing ‘RESET’ or ‘HORN EXCLUSION’ on

the front panel board or through the internal trimmer-adjusted timer (8).

With selector (5) engaged the alarm ceases as soon as the alarm conditions cease to exist; if selector

(5) Is disengaged the alarm keeps working until the manual intervention by the operator or of the turn

off timer.

Содержание SAR100

Страница 2: ...2 14 INDEX ITALIANO pag 3 ENGLISH page 8 LEGENDA KEY page 13...

Страница 13: ...13 14...

Страница 14: ...14 14...