MANUAL: 55308

REV: A

ECO: 49582

13

6.1.3 PCB CALIBRATION

PROCEDURE

Numerous precautions are taken at PCB to insure

accurate and repeatable results. This section

provides a brief overview of the primary areas of

concern.

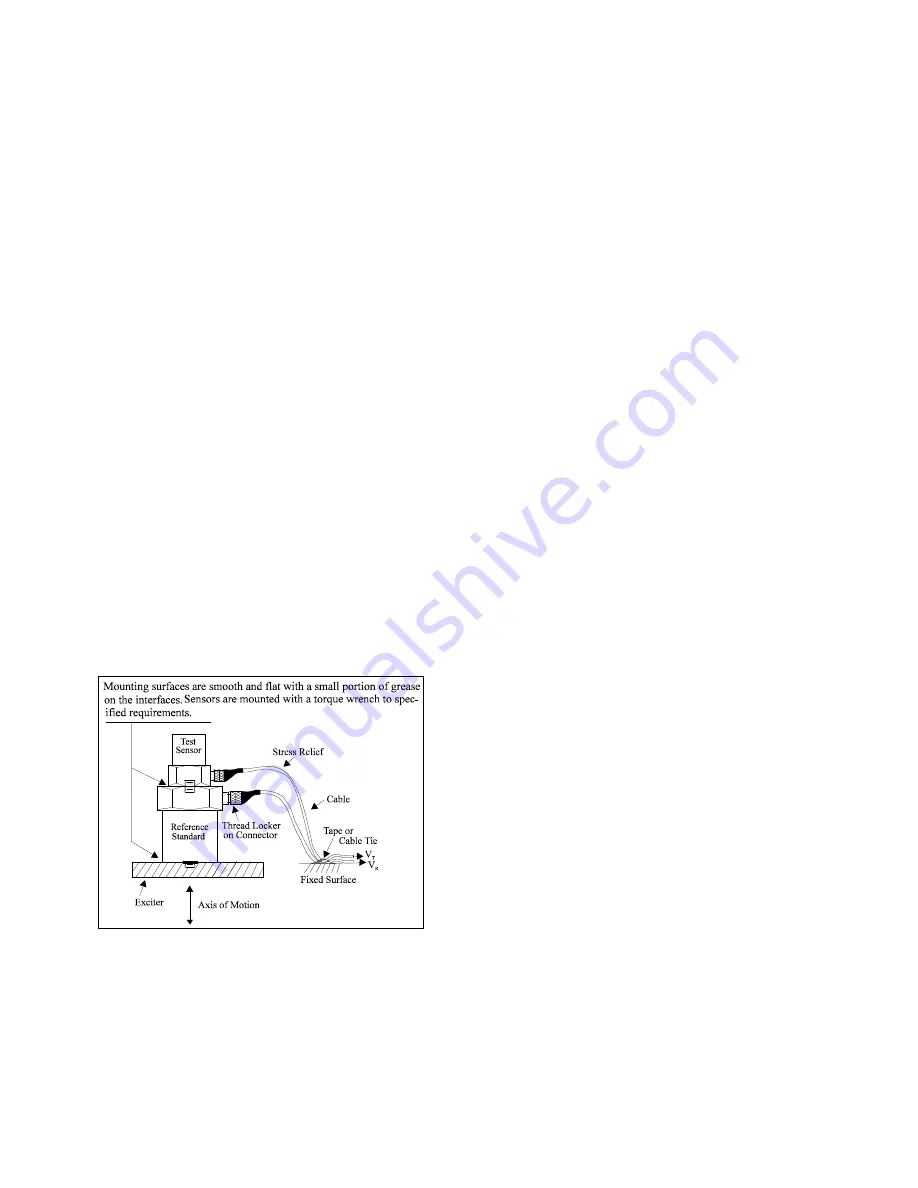

Since the Back-to-Back Calibration technique relies

on each sensor experiencing an identical

acceleration level, proper mounting of the test

sensor to the reference standard is imperative.

Sensors with mounting holes are attached directly

to the reference standard with a stud tightened to

the recommended mounting torque. A shouldered

mounting stud is typically used to prevent the stud

from “bottoming out” in the hole.

Both mounting surfaces are precision-machined

and lapped to provide a smooth, flat interface

according to the manufacturer’s specification. A

thin layer of silicone grease is placed between the

mating surfaces to fill any imperfections and

increase the mounting stiffness. The cables are

stress-relieved by first routing them to the shaker

head, securing them with tape or cable ties, then

routing them to a nearby stationary location. This

reduces cable motion, which is especially important

when testing charge output sensors and helps to

prevent extraneous noise or stresses from being

imparted into the system. A typical set-up is shown

in Figure 4.

Figure 4.

Typical Calibration Set-Up

Adhesively mounted sensors use similar practices.

However, in this case, a small portion of quick-

bonding gel or similar temporary adhesive is used

to attach the test sensor to a reference standard

designed with a smooth, flat mounting surface.

In addition to mounting, the selection of the proper

equipment is critical. Some of the more important

considerations include: 1) the reference standard

must be specified and previously calibrated over the

frequency and/or amplitude range of interest; 2) the

shaker should be selected to provide minimal

transverse (lateral) motion and minimal distortion;

and 3) the quality of the meters, signal generator,

and other devices should be selected so as to

operate within the limits of permissible error.

7.4 COMMON MISTAKES

Most calibration errors are caused by simply

overlooking some of the fundamental principals of

dynamics. This section attempts to address some

of the more common concerns.

For stud-mount sensors, always mount the

accelerometer directly to the reference standard.

Ensure that the mounting surfaces are smooth, flat,

and free of any burrs. Always use a coupling fluid,

such as silicone grease, in the mounting interface to

maintain a high mounting stiffness. Mount the

sensor

according

to

the

manufacturer’s

recommended mounting torque. DO NOT use any

intermediate mounting adaptors, as the mounted

resonant frequency may be reduced and thereby

compromise the high-frequency performance. If

necessary, use adaptor studs.