‐

17

‐

PATON

PRO-series

DC

MMA/TIG/MIG/MAG

to

save

gas.

Start

also

with

average

position

of

wire

feeding

speed

controller

on

the

feeding

machine

(~

6...8

m/min.)

and

average

source

voltage

(~19

V)

for

any

diameter

of

installed

wire

(Ф0.6...1.2

m).

This

configuration

may

be

not

optimum,

but,

under

condition

of

correct

work,

even

wire

feeding

(without

jerks)

and

correct

connection,

this

"source

+

feeding

machine"

combination

shall

be

able

to

weld

so

far.

For

better

results,

adjust

source

voltage

with

buttons

3

and

speed

of

wire

feeding

by

the

feeding

machine

according

to

general

recommendations

on

semiautomatic

welding.

Remember

that

these

parameters

are

different

for

each

specific

application.

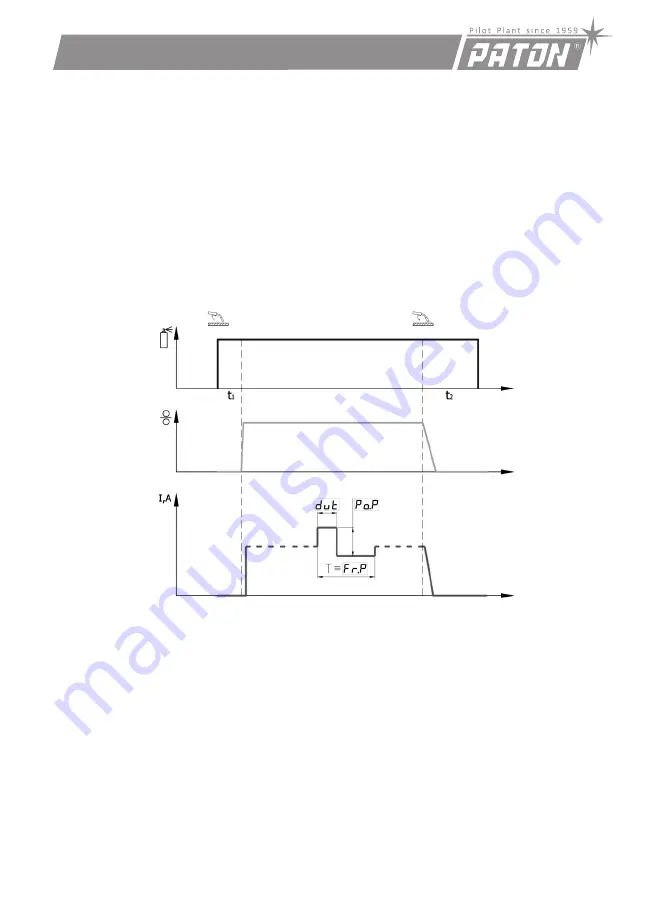

5.1

WELDING

CYCLE

–

MIG/MAG

See

paragraph

6.1

for

sequence

of

changing

parameters

of

functions.

Time

of

pre

‐

purging

(

t

1

)

and

post

‐

purging

(

t

2

)

with

shielding

gas

is

set

on

the

wire

‐

feeding

machine.

5.2

FUNCTION

OF

VOLTAGE

FADE

‐

OUT

IN

THE

END

OF

WELDING

This

function

is

designed

for

smooth

filling

of

a

crater,

which

is

formed

in

the

weld

pool

by

the

action

of

electromagnetic

draft

of

the

electric

arc

and

subsequently

becomes

a

source

of

weld

defects.

Release

of

the

torch

button

in

the

end

of

welding

becomes

the

signal

to

start

the

function.

Once

this

happens,

stop

moving

the

torch

and

weld

the

pothole

(which

is

a

crater)

in

the

weld

with

fading

‐

out

voltage.

Smoothness

of

this

process

can

be

controlled

through

voltage

fade

‐

out

time

[t.dn]

both

in

the

source

and

in

the

wire

feeding

speed

control

unit.

These

values

must

be

t,

s

t,

s

t,

s

Содержание PRO-160

Страница 1: ......