Bulletin 100-50-9.1 –

Page 75

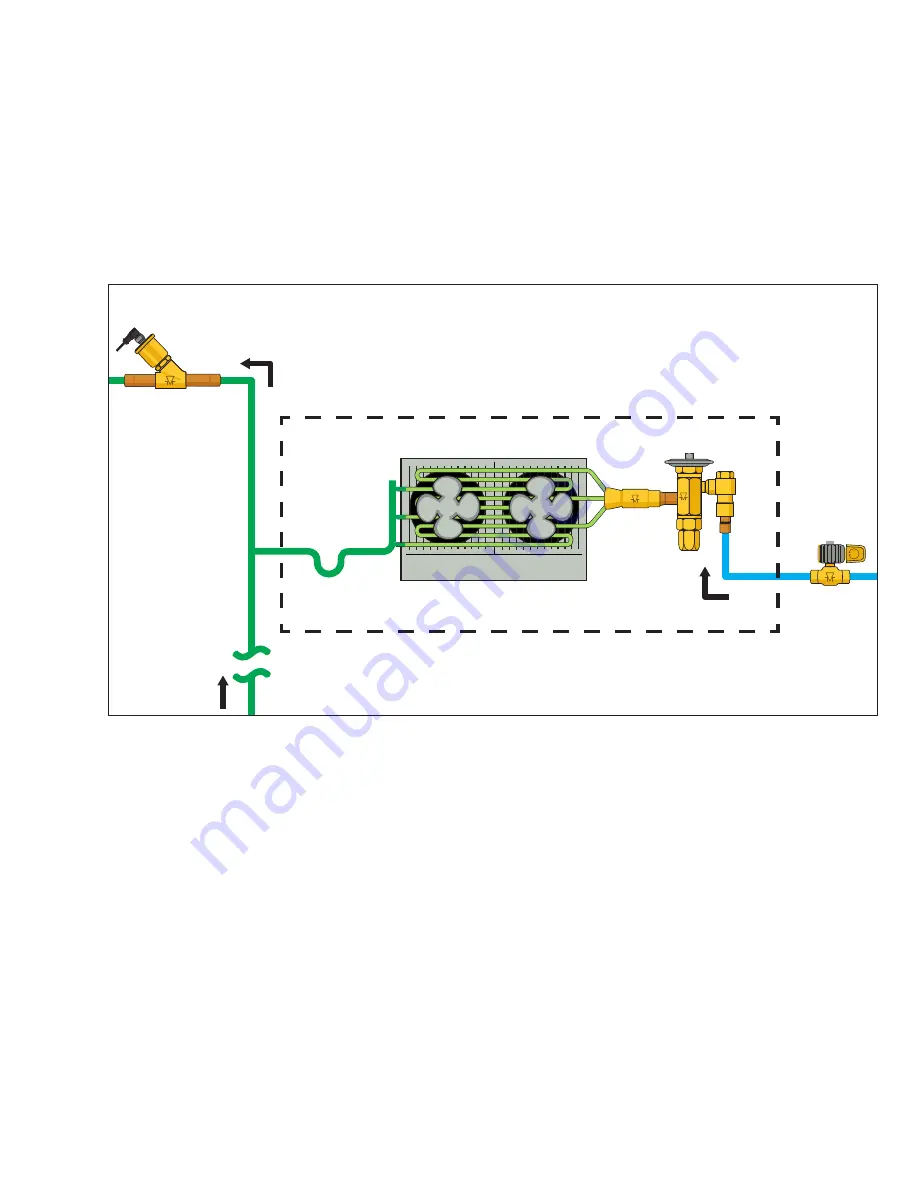

6.18 REMOTE DUAL TEMPERATURE WITH CIRCUIT EEPR – CONFIGURATION R

The S3C case controller is capable of controlling and monitoring dual temperature, single evaporator refrigerated fixtures

installed as a line-up. The case shown in the diagram below is the lead case of the line-up. In this scenario, one S3C case controller

is required. The S3C case controller will control all case functions as well as take all the desired sensor inputs for one evaporator

and drive the EEPR. The typical control method is to regulate the average discharge air temperature with the EEPR while allowing

the TEV to control superheat. Note that the required liquid line solenoid (LLS) may be installed as one-per-case or one-per-line-

up. In addition, only one case in the line-up (lead case) needs an EEPR connected to the S3C case controller. Case numbers 2,

3, 4,…n will require their own S3C case controller but will not have an EEPR connected to them if they share a common suction

line with the lead case shown in the diagram below. The case is toggled between its two operating temperatures either via the

building automation system (BAS) or with a locally installed physical switch. When the case controller receives a command to

change temperature, the EEPR will either open or close to lower or raise the case temperature, respectively.

To configure the S3C control package for configuration R

shown above, follow these directions:

If the controller has not been factory set, then upon initial

start-up, the controller will be in set-up mode and the screen

will display

(for self-contained case).

1. Press the

SET

button, then use

▲▼

buttons to scroll

to

o

; press

SET.

This will configure the controller to

support a remote case.

2. Press the

SET

button when

(Rack Identifier)

is displayed. Use the

▲▼

buttons to configure the 4

character Rack Identifier.

Note: Push

▲

button for

numeric,

▼

for alpha characters.

When satisfied

with each digit, press the

SET

button to go to the next

digit. Pressing

SET

multiple times will move to the next

parameter.

3. Press the

SET

button when

ud

(Line-up Identifier)

is displayed. Use the

▲▼

buttons to configure the 4

character Line-up Identifier.

Note: Push

▲

button for

numeric,

▼

for alpha characters.

When satisfied

with each digit, press the

SET

button to go to the next

digit. Pressing

SET

multiple times will move to the next

parameter.

4. Press the

SET

button when

d

(Case Identifier)

is displayed. Use the

▲▼

buttons to configure the 4

character Case Identifier.

Note: Push

▲

button for

numeric,

▼

for alpha characters.

When satisfied

with each digit, press the

SET

button to go to the next

digit. Pressing

SET

multiple times will move to the next

parameter.

5. Press the

SET

button when

(Application Type) is

displayed. Use the

▲

button and scroll to

du

(Dual

Temperature Case); press

SET.

6. Press the

SET

button when

(Local Stepper Valve

Configuration) is displayed. Use the

▲

button to scroll to

(Electronic Evaporator Pressure Regulator); press

SET.

This is the valve that is attached to the main S3C

Case Controller.

7. Press the

SET

button when

(Expansion Valve Type)

is displayed. Use

▲▼

buttons to choose the Expansion

Valve Type based on the below chart; press

SET.

8. Press the

SET

button when

(Building Automation

System Expected) is displayed. Use the

▲▼

buttons to

choose

e

or

o

; press

SET.

Compressor Suction

CASE

From CASE #n

Liquid

Liquid Line

Solenoid

EEPR (CDS)

REMOTE DUAL TEMPERATURE WITH CIRCUIT EEPR – CONFIGURATION R