- 5 -

8.2

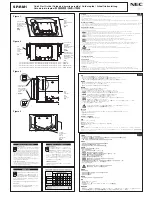

The following instructions cover the calibration

of the PanBlast

TM

AirScan Mobile CO Monitor.

8.3

Preparing the Calibration Connector

Test gas is completely dry and free of moisture

unlike normal air.

The sponge in the calibration humidifier

supplies the necessary moisture to the sample

gas. The sponge must be moist, but not wet.

To moisten the sponge:

(Reference Figure 4)

1

)

Press latch #4 to detach humidifier from

the valve.

2

)

Carefully add a few drops of distilled

water in the humidifier #2 to moisten the

sponge. The sponge must not be wet. If

necessary shake out any excess.

3

)

Attach humidifier #2 to the valve #5.

1)

3mm (1/8") OD tubing

2)

Humidifier tube

3)

Cal port connector

4)

Latch

5)

Needle valve

Figure 4

8.4

Proceed with calibration as outlined below.

Complete calibration requires use of impurity

free test gas to establish the correct zero

reading prior to further calibration. The

following instructions outline this procedure.

When impurity free test gas is not available, the

initial steps to set zero may be skipped and the

10 ppm carbon monoxide test gas may be used

to set the 10 ppm response and alarm.

1

)

On the calibration valve assembly, turn

the needle valve to the closed position.

2

)

Attach the calibration valve assembly to

the Impurity free test gas bottle.

3

)

Move the instrument RUN/CAL switch to

the CAL position.

4

)

Connect the calibration valve assembly

calibration connector to the instrument

test gas port.

5

)

Initiate gas flow into the instrument by

slowly turning the needle knob of the

calibration valve assembly to open.

Monitor the flow bar graph display to ensure

GREEN condition and allow the impurity free

gas to flow for at least one minute. Check the

air quality indicator to ensure it is GREEN.

6

)

If it is not GREEN adjust the calibration

adjustment screw to produce a GREEN

indication (Shown in Figure 3, page 4).

7

)

Remove the impurity free test gas from

the instrument and remove the calibration

valve assembly from the test gas bottle.

8

)

Attach the calibration valve assembly to

the 10ppm carbon monoxide gas bottle

and reconnect to the instrument test gas

port.

Allow 10 ppm carbon monoxide test gas to flow

for at least 20 seconds and check that the air

quality indicator has turned RED, if not:

9

)

Adjust the calibration adjustment screw

until the air quality indicator turns RED.

10

)

Reconnect the impurity free test gas.

Confirm that the instrument returns to a

GREEN air quality indication.

Properly secure the test gases and equipment.

8.5

INTERNAL BOARD SET-UP AND CONNECTORS

The PanBlast

TM

AirScan Mobile CO Monitor is

factory configured to operate on 220 VAC and

to alarm without delay when carbon monoxide

alarms or improper sample pressure occurs.

Internal controls and connectors allow user

modification of the factory settings as outlined

below.

To access the internal controls and connectors

the faceplate screw #8, Figure 3 must be

loosened and the faceplate opened. With the

faceplate fully opened the user has access to

sample lines, electrical connectors and the

mode select switch feature.

Revision of the factory set-up and connections must

be completed by a technician totally familiar with this

manual and the instrument application.

WARNING