195

UF-7300/7200

UF-8300/8200

Cleaning:

After transfer, residual toner remains on the drum surface, and for next printing, the residual toner reaches

to the development area via charge and exposure. The charge level of the OPC corresponds to the white

background is +900 VDC, and the bias voltage of the Conductive Roller is approx. +350 VDC. Therefore,

the positively charged residual toner on the OPC Drum is attracted and collected to the Conductive Roller.

The charge level of OPC after exposure is +100 VDC. So, the printing area of the OPC is cleaned.

6.3.2.4.

Transfer

As the paper is fed between the drum and the Transfer Roller, a high negative charge is applied to the back

of the paper. The positive toner particles are then attracted from the drum surface to the paper. After

transfer, the paper is separated from the drum surface by the curvature of the drum.

6.3.2.5.

Fusing

The paper passes through the Fuser Rollers and is subjected to heat and pressure. The fusing temperature

is approximately 190

°

C (374

°

F), and the pressure is approximately 0.36 k

g

/cm (3.53 N/cm). This bonds, or

fuses the toner into the paper.

6.3.3.

Paper Feed

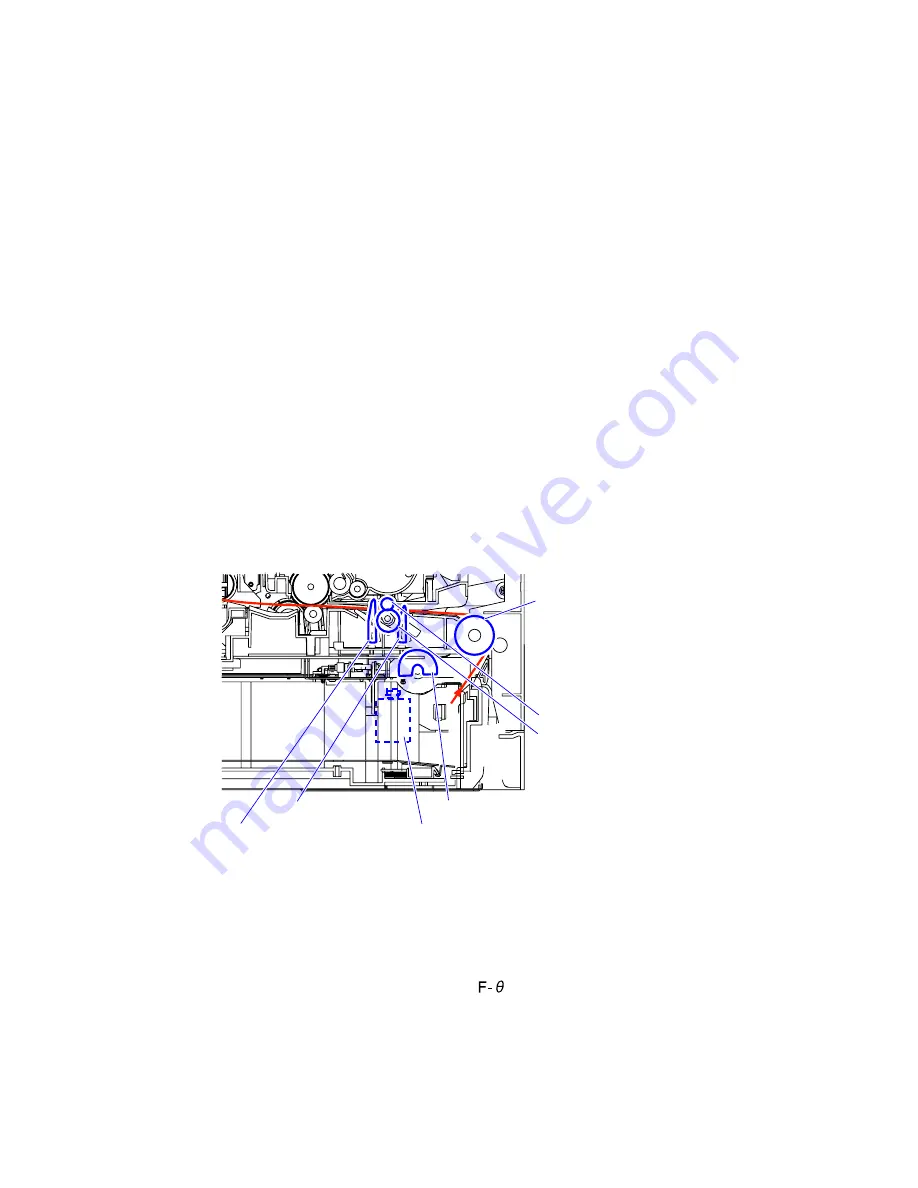

Media Tray

The main motor drives the Pick Up Roller after the Pick Up Solenoid is energized, which engages the Pick

Up Roller Clutch and feeds a sheet of paper. The paper is pushed to the Paper Feed Roller, which

overdrives the paper slightly causing a buckle to ensure the paper is aligned with the stationary Registration

Roller.

While triggering the Registration Sensor notifying the CPU paper is ready to feed.

6.3.4.

Laser Scan Unit (Exposure)

6.3.4.1.

Operation Theory

The light beam from the Laser Diode (light source) is modulated by the digital signal (nVIDEO) and

converted to parallel light waves by the Collimator Lens. The beam is then sent to the rotating Polygon

Mirror (polygon scanner), where it is reflected through the

Lens and then focused onto the OPC Drum

surface. The diameter of the beam is about 80

µ

m, and the light moves across the surface of the OPC Drum

in the scanning direction of right to left. As the drum rotates (sub-scans), a static image is formed where the

laser beam touches the drum surface.

The laser beam is also deflected to the Timing Sensor. This sensor controls the start timing of scanning on

the drum, providing a consistent left margin. The CPU uses the Timing Sensor to detect abnormal signals.

Feed Roller

Pick Up Roller

Pinch Roller

Pickup Solenoid

Registration Roller

Registration Sensor

Paper Path Sensor

Содержание UF-8300

Страница 5: ...5...

Страница 10: ...10...

Страница 11: ...11...

Страница 12: ...12...

Страница 232: ...232 UF 7300 7200 UF 8300 8200 memo...

Страница 233: ...DZSD001829 15 Panasonic Software Operating Instructions Network Firmware Update Tool for Service Technicians Version 3...

Страница 246: ...Network Firmware Update Tool LAN Page 14 13 Confirm the message in the text box and click OK to close the tool or...

Страница 247: ...DZSD000965 18 Panasonic Software Operating Instructions Local Firmware Update Tool for Service Technicians Version 3...

Страница 261: ...Published in Japan...