4.6.2

System Integrity Test (External Test)

Procedure

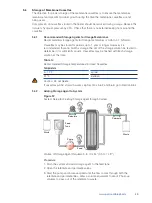

1. Connect the integrity test unit to the system.

The integrity tester may be connected as shown in Figure 23, or disconnect the

pump and attach the air supply from the integrity analyzer in its place. The integrity

tester may also be connected to the retentate line if an isolation valve is placed

between the feed port and pump.

2. Close the permeate valve and any other valves in the feed and retentate flow path

as required to allow the system to be pressurized with air.

3. Charge the system to a pressure of 2 barg (30 psig).

4. The airflow rate displayed on the integrity test unit will increase at first, then drop

off. As the pressure stabilizes to 2 barg (30 psig), the air mass flow rate should

decrease to zero (as shown in the example given in Figure 23).

If the mass flow rate = zero (< 5 sccm for membrane area > 0.1 m

2

[1 ft

2

]), the

system integrity has passed, so continue with step 5.

If the mass flow rate levels off above zero (> 5 sccm), go to Section 4.6.4.

On some systems, it may take 15 minutes or longer for airflow to drop to zero, since

the air diffuses through the membrane to pressurize the permeate side. If there is still

airflow (> 5 sccm) after the permeate and feed/retentate pressures are equal, a leak

is indicated.

5. Once the system pressure test has been completed, slowly open the permeate

valve to relieve the pressure.

6. Slowly open the integrity outlet valve or the retentate valve to reduce the air

pressure to zero in the feed/retentate channels.

7. Close the integrity outlet valve or retentate valve.

4.6.3

Membrane Cassette Integrity Test

Membrane Type: Omega

Cassette Format: Centramate, Centrasette

Channel Format: Screen

Procedure

1. Set the pressure on the integrity test unit to the value listed in Table 12.

2. Open the permeate valve.

Table 12

Air Integrity (Forward Flow) Specifications for T-Series Cassettes with

Omega Membrane

Allowable Air Forward Flow

Membrane NMWC

Test Pressure

Rate per Unit Area of Membrane

≤

300 kD

2.0 barg (30 psig)

≤

1600 sccm/m

2

(

≤

150 sccm/ft

2

)

3. Turn on the air supply from the integrity tester to pressurize the system.

4. The air flow rate displayed on the integrity test unit will initially increase as the

system pressurizes, then drop before leveling off to a constant flow rate. This

measured constant mass flow rate is the air forward flow (diffusion) rate

(Figure 23).

www.pall.com/biopharm

33