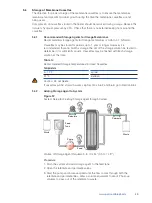

Figure 30

System Setup for Recirculation

Procedure

1. Set up the system for recirculation (Figure 30).

2. Fill the feed tank with required volume of water.

3. Open the retentate and permeate valve.

4. Adjust the pump to deliver a flow rate of 5 L/min/m

2

(0.5 L/min/ft

2

).

5. Adjust the retentate valve to split flow 75% retentate, 25% permeate.

6. Readjust pump to give required retentate flow rate.

7. Recirculate for 30 minutes.

8. Direct retentate and permeate lines to drain.

9. Drain the system.

10. Perform steps 5.3.1 and 5.3.2 using minimum volumes of water for flush.

Take samples of retentate and permeate from the effluent at end of flush and

assay. If the pH, TOC, and extractable levels are not acceptable, repeat steps 2

to 10 until acceptable levels have been obtained.

5.4

Determine Membrane Recovery for the Cassettes

Membrane recovery is a calculation to determine the efficiency of the cleaning performed on the

membranes. It compares the normalized water permeability (NWP) after cleaning to the initial

NWP, measured when the membrane was first installed and preconditioned (Section 4.5).

Water quality should be Water for Injection (WFI) or, at minimum, 0.2 µm filtered DI water. All

water permeability rates are normalized to a temperature of 20 °C by using a temperature

correction factor (TCF

20 °C

) obtained from Table 11.

www.pall.com/biopharm

41

Retentate

Permeate

Feed

Tank

Feed

Pump

Rp

Pp

Fp