15

PZ Series 150-250-500-1000 Shaker Cleaner

Optional Equipment

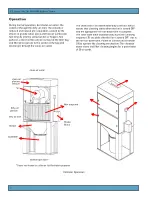

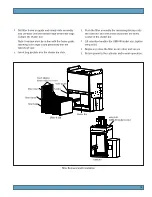

Magnehelic Gauge Installation

Magnehelic

®

Gauge

The Magnehelic is a differential pressure gauge used

to measure the pressure difference between the clean-

air and dirty-air plenums and provides a visual display

of filter change requirements. The high-pressure tap is

located in the dirty-air plenum and the low-pressure tap

is located in the clean-air plenum.

1. Choose a convenient, accessible location on or near

the collector for mounting that provides the best

visual advantage.

2. Plug the pressure ports on the back of the gauge

using two, 1/8-in NPT pipe plugs supplied. Install two,

1/8-in NPT male adapters supplied with the gauge

into the high- and low-pressure ports on the side of

the gauges.

3. Attach the mounting bracket using three, #6-32 x 1/4-

in screws supplied.

4. Mount the gauge and bracket assembly to the

supporting structure using two, self-drilling screws.

5. Thirty-five feet of plastic tubing is supplied and must

be cut in two sections. Connect one section of tubing

from the gauge’s high-pressure port to the pressure

fitting located in the dirty-air plenum. Connect

remaining tubing from the gauge’s low-pressure

port to the fitting in the clean-air plenum. Additional

tubing can be ordered from your representative.

6. Zero and maintain the gauge as directed in the

manufacturer’s Operating and Maintenance

Instructions provided.

collector ref only

plastic tubing

screw

washer

mounting panel

high-pressure port

Magnehelic gauge

high pressure ref only

low pressure ref only

two, self-drilling screws

1/8-in NPT x 90° male elbow

low-pressure port