12

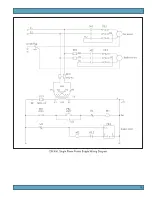

Typical Start-Up Sequence

Press the Start button on the controller panel to start the

collector.

Typical Shut-Down Sequence

1. Press the Clean button on the controller.

2. The fan stops when fan run-down cycle is complete.

3. The cleaning cycle starts and when finished, the

collector turns OFF.

Instruct all personnel on safe use and maintenance

procedures.

Electrical work during

installation, service or

maintenance must be performed by a qualified

electrician and comply with all applicable

national and local codes.

Turn power off and lock out all power before

performing service or maintenance work.

Check that the collector is clear and free of all

debris before starting.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Preliminary Start-Up Check

5. Check and remove all loose items in or near the inlet

and outlet of the collector.

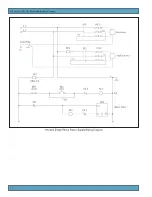

6. Check that all remote controls and solenoid

enclosures (if applicable) are properly wired and all

service switches are in the OFF position.

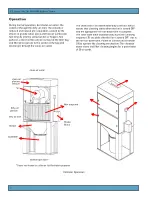

7. Check that all optional accessories are installed

properly and secured.

8. Turn power ON at source.

9. Turn fan motor ON.

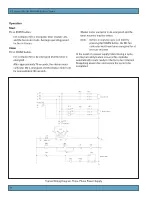

1. Check all electrical connections for tightness and

contact.

2. Check for proper rotation on all motors as described

below.

To reverse rotation, single-phase power supply:

Follow manufacturer’s instructions on the motor’s

nameplate.

To reverse rotation, three-phase power supply:

Switch any two leads on the motor junction box.

Do not look into fan outlet to

determine rotation. View the fan

rotation through the back of the motor.

Check that the exhaust plenum is free of tools

or debris before checking blower/fan rotation.

Stand clear of exhaust to avoid personal injury.

Do not interchange a power lead with the

ground wire. Severe personal injury and/or

property damage may result.

3. All access panels should be sealed and secure.

4. Check that the dust container is properly sealed and

clamped.

10. Adjust airflow with the exhaust damper.

Excess airflow can shorten filter

life, cause electrical system

failure and fan motor failure.

PZ Series 150-250-500-1000 Shaker Cleaner