5

The static brake is released by the brake valve pilot

pressure at a pressure lower than that required to open

the pilot operated spool valve. This sequence assures

that dynamic braking takes place in the brake valve and

that little, if any, heat is absorbed by the friction brake.

The friction brake is a load holding brake only and has

nothing to do with dynamic braking or rate of descent of

a load.

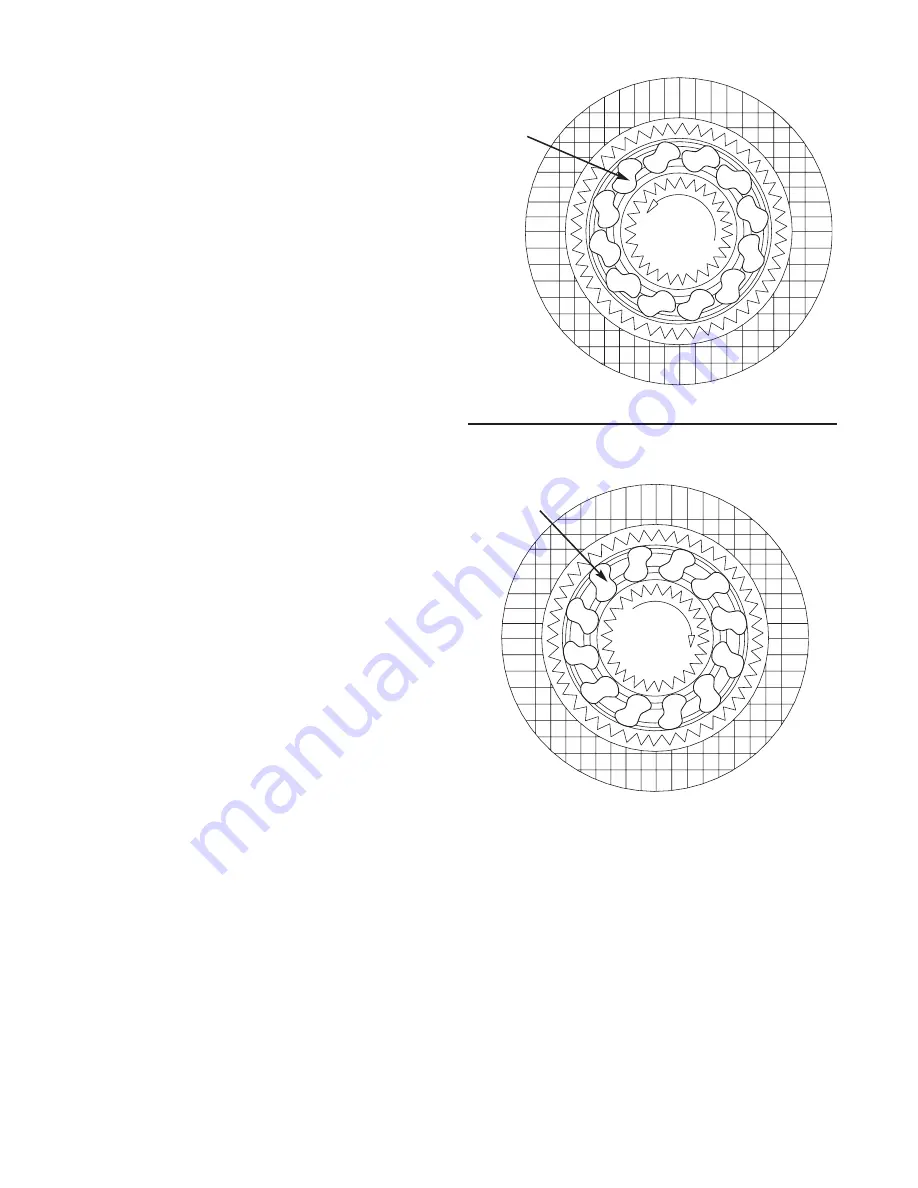

The brake clutch is splined to the primary sun gear shaft

between the motor and the primary sun gear. It will

allow this shaft to turn freely in the direction to raise a

load and lock up to force the brake discs to turn with the

shaft in the direction to lower a load. Figures 5 and 6.

The hydraulic cylinder, when pressurized, will release

the spring pressure on the brake discs, allowing the

brake discs to turn freely.

D

UAL

B

RAKE

S

YSTEM

– O

PERATION

When hoisting a load, the brake clutch which connects

the motor shaft to the primary sun gear, allows free rota-

tion. The sprag cams lay over and permit the inner race

to turn free of the outer race. Figure 5. The friction brake

remains fully engaged. The winch, in raising a load, is

not affected by any braking action. Figure 2.

When the lifting operation is stopped, the load attempts

to turn the primary sun gear in the opposite direction.

This reversed input causes the sprag cams to instantly

roll upward and firmly lock the shaft to the fully engaged

friction brake. Figure 6.

When the winch is powered in reverse, to lower the

load, the motor cannot rotate until sufficient pilot pres-

sure is present to open the brake valve. Figures 3 & 4.

The friction brake within the winch will completely

release at a pressure lower than that required to open

the brake valve. The extent to which the brake valve

opens will determine the amount of oil that can flow

through it and the speed at which the load will be low-

ered. Increasing the flow of oil to the winch motor will

cause the pressure to rise and the opening in the brake

valve to enlarge, speeding up the descent of the load.

Decreasing this flow causes the pressure to lower and

the opening in the brake valve to decrease thus slowing

the descent of the load.

When the control valve is shifted to neutral, the pres-

sure will drop and the brake valve will close, stopping

the load. The friction brake will engage and hold the

load after the brake valve has closed.

The friction brake receives very little wear in the lower-

ing operation. All of the heat generated by the lowering

and stopping of a load is absorbed by the hydraulic oil

where it can be readily dissipated.

Figure 5

Static Friction Brake Applied

Sprag

Cams

Permits free

shaft rotation

while hoisting

Hoisting

Figure 6

Static Friction Brake Applied

Load attempts to rotate shaft in opposite direction.

Brake clutch locks sun gear shaft to friction brake.

Sprag

Cams

Stopped,

Holding

Load

Содержание BRADEN H20R

Страница 27: ...26 BRADEN H20R 05559 COMPONENTS ...