10

Pre-Use or Daily Inspection:

Must include but is not limited to the following inspec-

tions that will be performed prior to placing the hoist into

service and then as necessary during extended opera-

tion. This inspection must be performed by a qualified

technician.

1. Check for external oil leaks and repair as necessary.

This is extremely important due to the accelerated

wear that will result from insufficient lubricating oil in

the hoist. Check the oil level monthly if no external

oil leaks are detected.

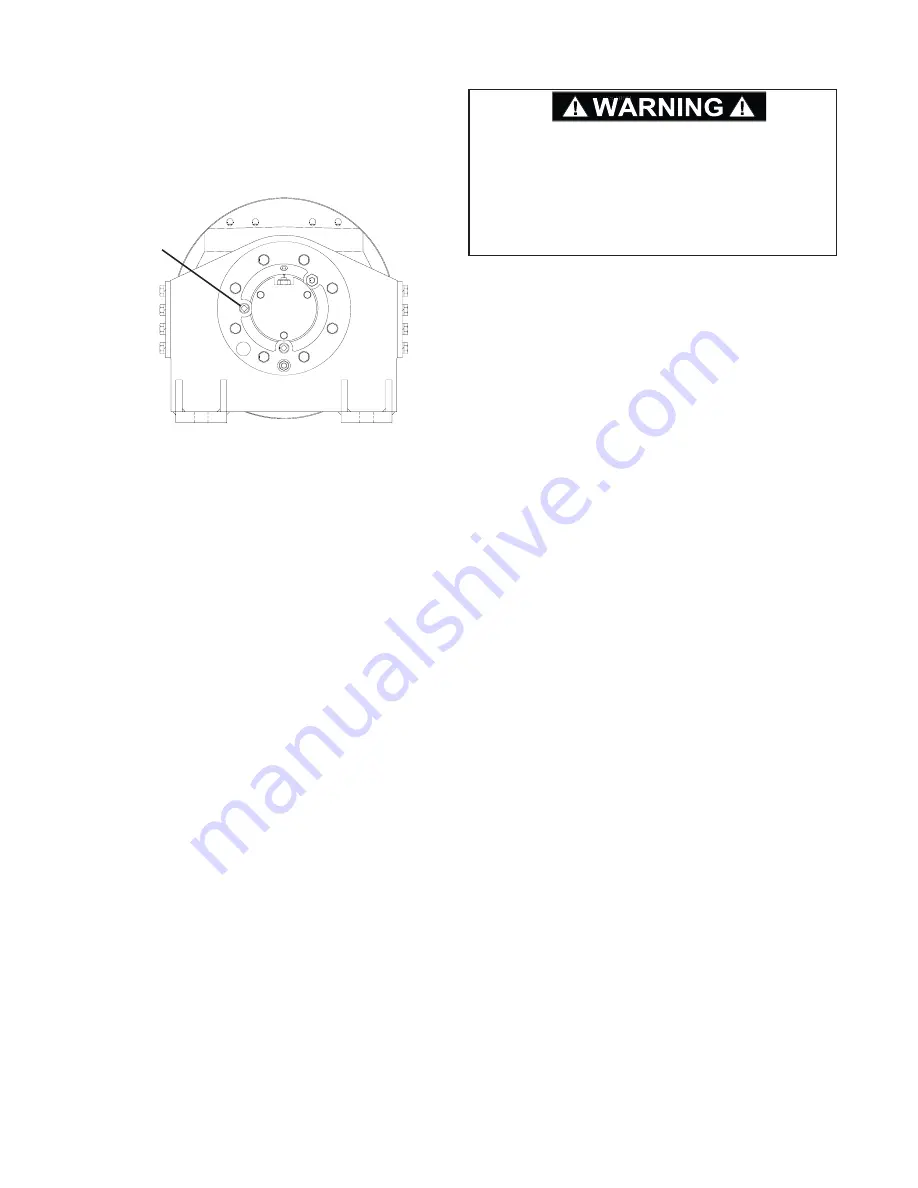

Check the oil level by removing the plug located at

the 9 o'clock position on the drum bearing support

housing. The oil level must be at the bottom of the

level plug port.

2. Check the hydraulic fittings and hoses for leaks,

chaffing, deterioration or excessive corrosion and

repair as required.

3. Visually inspect for corroded, loose or missing fas-

teners and tighten or replace as required.

4. Inspect the entire length of wire rope and rigging as

recommended by the wire rope and rigging manu-

facturer.

5. Inspect all safety devices such as anti-two-blocking

switches and limit switches and repair as required.

6. A warm-up procedure is recommended at each start-

up and is essential at ambient temperatures below

40°F (4°C). The engine should be run at low RPM

with the hoist control valve in neutral allowing suffi-

cient time to warm up the hydraulic system. The

hoist should then be operated without a load, at low

speeds, raise then lower several times to prime all

lines with warm hydraulic oil and to circulate gear

lubricant through the planetary gear train.

Semi-Annual Inspection

(every six months):

Must include but is not limited to the following inspec-

tions performed by a qualified technician.

1. Perform the Pre-Use inspection.

2. Take a lubricant sample as described later in this

section and analyze it for wear metals content, cor-

rect viscosity, lubricant deterioration, moisture and

other contaminants. If the oil sample contains a high

amount of metallic particles, the hoist must be taken

out of service to undergo a tear-down inspection.

Note: Oil analysis can not detect nor warn against a

fatigue failure.

3. Perform a brake test as described later in this sec-

tion.

4. Inspect/tighten all hoist mounting fasteners to rec-

ommended torque.

5. Service the hydraulic system oil and filters as recom-

mended by the vehicle manufacturer.

Annual Inspection:

Must include but not limited to the following inspections

that must be performed by a qualified technician.

1. Perform the Pre-Use and Semi-Annual inspections.

2. Change hoist gear cavity lubricating oil after an oil

sample has been taken as described later in this

section. Refill the hoist to the proper level with rec-

ommended lubricant. Refer to "Recommended

Planetary Hoist Gear Oil" later in this section for

more information.

Failure to properly warm up the hoist, particularly

under low ambient conditions, may result in tempo-

rary brake slippage due to thick gear oil in the brake

clutch assembly or hydraulic system back-pressure

attempting to release the brake, which could result in

property damage, injury or death..

Oil Level Port

Содержание BRADEN H20R

Страница 27: ...26 BRADEN H20R 05559 COMPONENTS ...