(1) Cassette paper feed operation

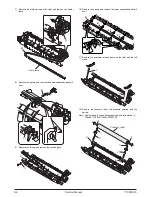

1) The figure below shows the positions of the pick-up roller, the

paper feed clutch sleeve, and the paper feed latch in the initial

state without pressing the COPY button after lighting the ready

lamp.

The paper feed latch is in contact with the projection of the

clutch sleeve.

2) When the COPY button is pressed, the main drive motor starts

rotating to drive each drive gear.

The pick-up drive gear also is driven at that time. Since, how-

ever, the paper feed latch is in contact with the projection of

the clutch sleeve, rotation of the drive gear is not transmitted to

the pick-up roller, which does not rotate therefore.

3) After about 0.1 sec from when the main motor start rotating,

the tray paper feed solenoid (PFS) turns on for a moment.

This disengages the paper feed latch from the projection of the

clutch sleeve, transmitting rotation of the pick-up drive gear to

the paper feed roller shaft, rotating the pick-up roller to feed

the paper.

4) After more than half rotation of the pick-up roller, the paper

feed latch is brought in contact with a notch on the clutch

sleeve, stopping rotation of the pick-up roller.

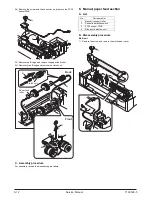

5) At this time, the paper is fed passed the paper entry detection

switch (PPD1), and detected by it. After about 0.15 sec from

detection of paper by PPD1, the tray paper feed solenoid

(PFS) turns on so that the clutch sleeve projection comes into

contact with the paper feed latch to stop the pick-up roller.

Then the pick-up roller rotates for about 0.15 sec so that the

lead edge of the paper is evenly pressed on the resist roller,

preventing against skew feeding.

6) To release the resist roller, the tray paper feed solenoid and

the resist solenoid are turned on by the paper start signal to

disengage the resist start latch from the clutch sleeve, trans-

mitting rotation of the resist drive gear to the resist roller shaft.

Thus the paper is transported by the resist roller.

7) After the resist roller starts rotating, the paper is passed

through the pre-transfer guide to the transfer section. Images

are transferred on the paper, which is separated from the OPC

drum by the drum curve and the separation section.

8) The paper separated from the drum is passed through the fus-

ing paper guide, the heat roller (fusing section), POD (paper

out detector) to the copy tray.

OFF

PFS

OFF

RRS

OFF

PFS

OFF

RRS

ON

PFS

OFF

RRS

OFF

PFS

ON

RRS

Y109500-5 Service Manual 7-5

Содержание d-Copia 200D

Страница 1: ...d Copia 200D d Copia 201D Digital Copier SERVICE MANUAL Code Y109500 5...

Страница 6: ...This page is intentionally left blank...

Страница 8: ...This page is intentionally left blank 1 2 Service Manual Y109500 5...

Страница 12: ...This page is intentionally left blank 2 4 Service Manual Y109500 5...

Страница 22: ...This page is intentionally left blank 4 8 Service Manual Y109500 5...

Страница 28: ...This page is intentionally left blank 5 6 Service Manual Y109500 5...

Страница 86: ...This page is intentionally left blank 10 20 Service Manual Y109500 5...

Страница 94: ...This page is intentionally left blank 12 6 Service Manual Y109500 5...

Страница 96: ...UPDATING STATUS DATE UPDATED PAGES PAGES CODE 05 2008 1ST EDITION 96 Y109500 5...