-

15

-

6

.

MAINTENANCE

A dirty rail groove may interfere with the screw transport speed.Clean the dirty rail with a soft, clean cloth dipped in

alcohol.If cleaning is difficult, remove the rail from the machine and clean the rail groove.

Refer to Operation Manual of maintenance on our website for replacing. Before removing the rail from the machine, be

sure to turn off the power supply and take the screws out of the hopper.If there is any dirt or a flaw in the rail groove that

may cause an impediment in use, we recommend the user to replace the rail.

Signal line

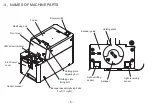

7. Application with Robotic System

7

-

1

.

External Output Signals

The wires coming out from the back of the machine serves as the

detection of presence of screws on the rotational escaper, which

shall be used with automatic assembly machines or external screw

counters.

[Function]: Screw present: signal high (ON)

Incoming current: shall be limited to less than 100mA

**CAUTION: Additional resistor is required on

external circuit for regulating current **

[Capacity]: Max DC current: 100mA

External supply voltage: 5 ~24VDC

(Max: 27VDC)

[note]: Please keep the length of output signal wire

less than 3m;

* The purple wire functions as signal output high

(Collector end), with the gray wire as common (Emitter end)

Purple wire--->Signal line (OFF when no screw is present)

(On when a screw is present)

Gray wire --->Common line

CN10

Purple wire

Gray wire

Example of connection

Inseide of the feeder

Outseide of the feeder

Содержание OM-26RB Series

Страница 23: ...22...