-

14

-

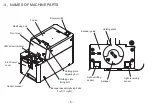

Scraper-left

Scraper-right

Hopper wall-left

Scraper

attaching screws

Clearance around

0.4mm

Timer adjusting knob

(the 3rd hole from the top)

Shorter

Longer

Check the lapse of time until the motor

stops by intercepting the front sensor.

(Use a small peice of paper to intercept

the sensor.)

Edge of the plate with angled-cut corner shall be on

the upper side, facing the rail.

5- 10.

Check and adjust the timer

The screw transport feed differs depending on screw type.

This machine can make screw unloading smooth through timer adjustment. For screws

with a low transport speed, set the timer long. For screws with a high transport speed,

set the timer short.

5- 11.

Check and adjust the scraper

・

Check that the clearances, between the scraper right/left and the hopper wall right/

left, are around 0.4mm.

・

When the scraper makes contact with the hopper wall, the rail vibration becomes

weak and the screws are delivered slowly. When the clearance between the scraper

and the hopper wall is too large, the screws may be caught easily.

・

If any adjustment is required, loosen the scraper attaching screw and move the

scraper plate up or down.

・

After such adjustments, if deformation on the plate has occurred so that proper

clearance and adjustment cannot be achieved, or scratches on the plates had

caused trouble in screw movement, please purchase replacement parts for best

results.

Left Scraper : TPO91201

Right Scraper: TPO91202

・

This machine continues its operation when no screw is found at the screw pick up

spot. The machine continues operating with a screw at the pick up spot but will

stop, after a certain lapse of time, if the screw is not picked up. This time lapse can

be varied by adjusting the timer. After the screw is picked up, the machine starts

operating again.

・

Check the operation by intercepting the optical axis of the sensor, covering one of the

sensors.

・

Make an adjustment with the timer adjusting knob (the 3rd hole from the top) at the

rear of the machine body (as shown in the figure on the right).

・

When the timer knob is turned clockwise, as viewed from the rear side,

the time becomes shorter. When the knob is turned counterclockwise,

the time becomes longer.(about 1

~

6 sec.)

Содержание OM-26RB Series

Страница 23: ...22...