-

11

-

5-4.

Checking and adjusting the rail vibration

The amplitude of the rail vibration can be adjusted.

The vibration has been adjusted at the factory for screws that correspond

with the rail.

Put some screws into the rail and turn the power on. If they are delivered

smoothly, there is no need for adjustment.

The screw transport feed differs depending on screw type.

For screws with a low transport speed, or screws that easily jump out, an

adjustment is necessary.

・

Turn the amplitude adjusting knob (second hole from the top) and find the

amplitude for which screws are delivered smoothly.

・

If the vibration is adjusted to a too large a value to increase the transport

speed, screws may jump from the rail and fall into the machine from the

clearance, failing to unload screws normally.

Adjust the vibration to a proper value that matches the loaded screws.

・

With the accompanying screwdriver, turn the knob without using excessive

force.

・

When no screws are scooped onto the rail for a certain period of time, the rail

vibration increases. If, still, no screws are scooped on to the rail, the machine

stops operating.

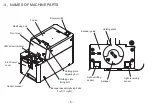

Amplitude adjusting

knob

Timelag adjusting knob

Small

Large

Shorter

Longer

5- 5.

Checking and adjusting the escaper time lag

This machine can adjust the time it takes for the escapar to rotate after picked up the screws. The standard setting time is the shortest.

If the escapar rotates before you can remove the screw with an automation machine set etc, adjust the time lag to a longer setting.

・

Adjust with the 1st volume from the back of the aircraft as shown on the right.

・

When the timer knob is turned clockwise, as viewed from the back side, the time becomes shorter.

When the knob is turned counterclockwise, the time becomes longer.

・

During the time lag, the screw detection LED will remain lit even if the screw is taken out.

・

Please make this adjustment, by using the accompanying screwdriver, within the allowable turning range, without using excessive force.

・

After adjustment, please insert some screws to check the pick-up operation, to confirm the appropriate time lag setting.

Содержание OM-26RB Series

Страница 23: ...22...