N1200HC Controller

NOVUS AUTOMATION

5/12

RECOMMENDATIONS FOR THE INSTALLATION

•

The wires of the input signals must be disposed separated of the

power and outputs wirings, if possible, in grounded ducts.

•

All electronic instruments must be powered by a clean mains

supply, proper for instrumentation.

•

It is strongly recommended to apply RC'S FILTERS (noise

suppressor) to contactor coils, solenoids, etc.

•

In any application it is essential to consider what can happen when

any part of the system fails. The controller features by themselves

can not assure total protection.

ELECTRICAL CONNECTIONS

The controller's internal circuits can be removed without undoing the

connections on the back panel.

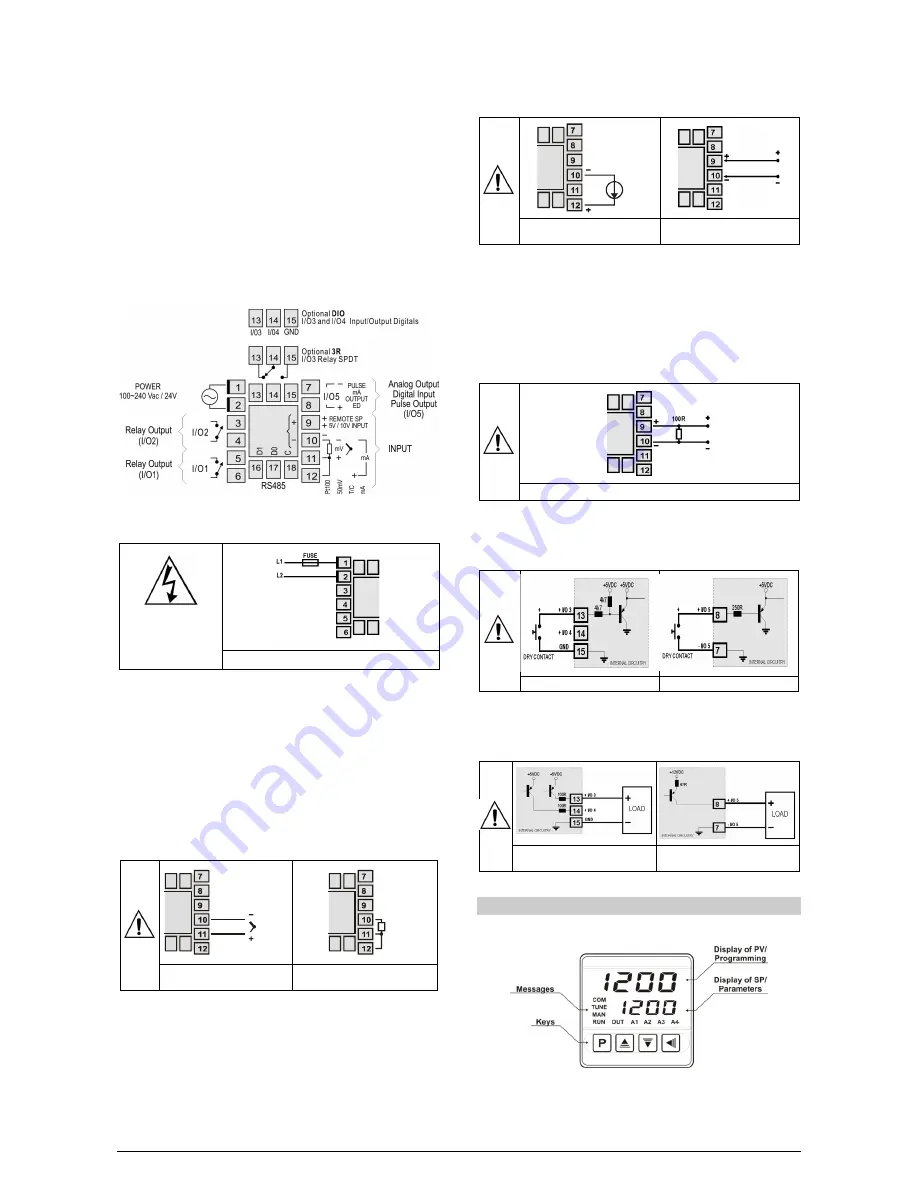

The controller complete set of features is drawn in

Figure 1

:

Figure 1

- Connections of the back panel

Power Supply Connections

Observe the power

requirement for the

unit. of required power

supply

Figure 2

– Power supply connections

Input Connections

•

Thermocouple (T/C) and 0-50 mV

The

Figure 3a

indicates the wiring for the thermocouple and 0-50mV

signals. If the thermocouple wires needs to be extended, use

appropriate compensation cables.

•

RTD (Pt100):

Figure 3b

shows the Pt100 wiring, for 3 conductors. For proper cable

length compensation, use conductors of same gauge and length).

For 4-wires Pt100, leave one conductor disconnected at the

controller. For 2-wire Pt100, short-circuit terminals 11 and 12.

T/C, 0-50mV

Pt100

Figure 3a

- Connection of T/C, 0-

50mV

Figure 3b

- Connection of three wire

Pt100

•

4-20 mA:

The connections for current signals 4-20 mA must be carried-out

according to

Figure 4a

.

4-20mA

Figure 4a

- Current connection

4-20 mA

Figure 4b

- Connection for 5 V and

10 V

•

5 V and 10 V

Refer to

Figure 4b

for connecting voltage signals.

Remote Setpoint

Feature available in the controller's terminals 9 and 10. When the

Remote SP input signal is 0-20 mA or 4-20 mA, an external

100

Ω

shunt resistor of must be connected to terminals 9 and 10 as

indicated in

Figure 4c

.

Figure 4c

- Connection for remote SP

Digital Input Connections

To use the I/O channels I/O 3, I/O 4 or I/O 5 as Digital Inputs connect

a switch (Dry Contact) at its terminals.

Figure 5a

– I/O3 a Digital Input

Figura 5b

– I/O5 a Digital Input

Connection of Alarms and Outputs

The I/O channels, when configured as outputs, must have their load

limit capacities observed, according to the product specifications.

Figure 6a

– I/ O3 or I/O4 with output

pulse for SSR.

Figure 6b

–

I/O5 with output pulse

for SSR.

OPERATION

The controller's front panel, with its parts, can be seen in the

Figure 7

:

Figure 7

- Identification of the parts referring to the front panel