N1200HC Controller

NOVUS AUTOMATION

4/12

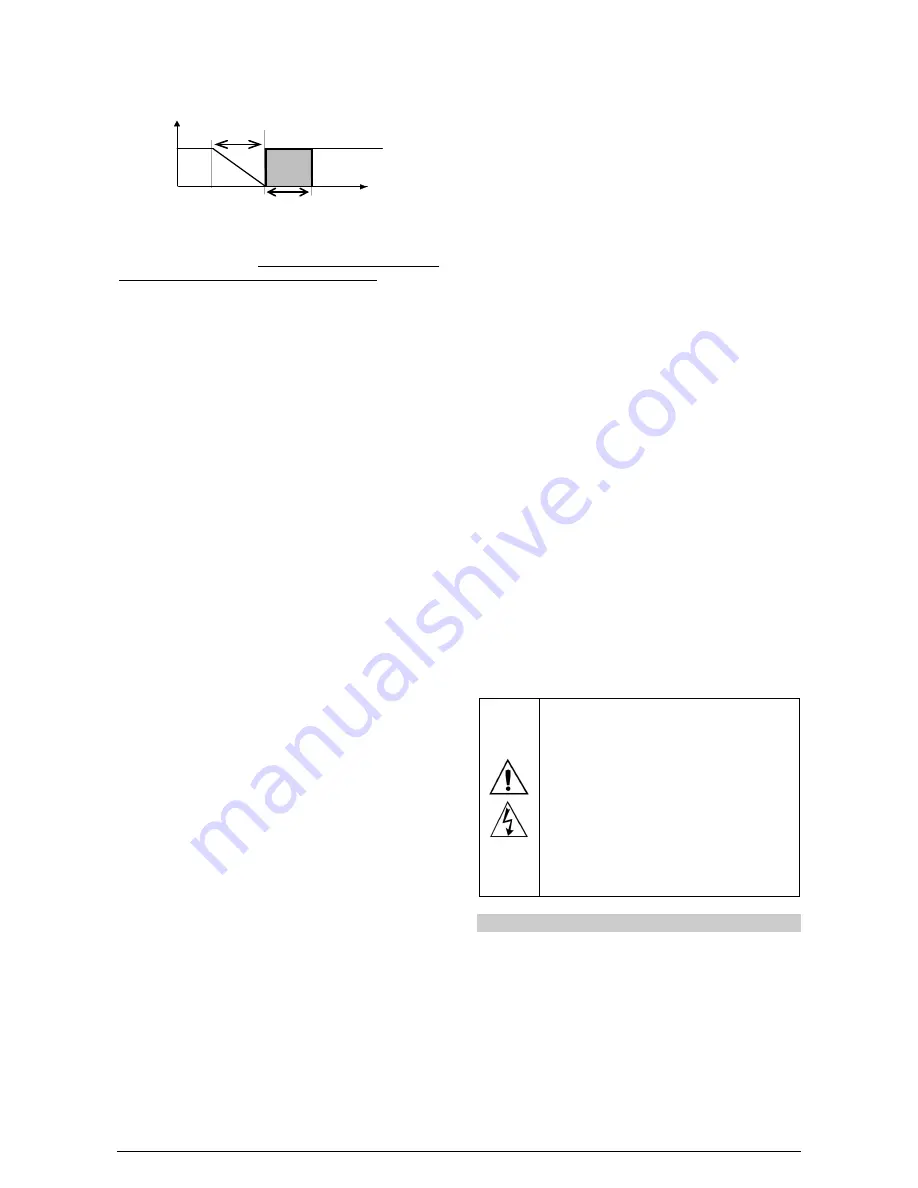

The proportional band 2 (Pb2) and the level time of PWM 2 (Ct2) are

independent. Here you must set the minimum and maximum power

for control 2.

Control Output

Process Variable

Pb1

Hst 2

Output 1

Output 2

OFF

ON

Set Point

RUN

MODE

The RUN parameter (

rvn

) operates as a master switch of the

controller outputs channels. It enables either the channels set to

control output as the defined as an alarm output. When this

parameter is settled to

YES

, the control outputs and alarm are able to

operate on and off in accordance to the determinations of the

controller. When it is settled to

NO

, all outputs remain off, regardless

of the needs of the process. In this condition, the display of the

controller shows a

STOP

message alternately with the measured

temperature value (PV).

ANALOG RETRANSMISSION OF PV AND SP

The analog output (available in I/O5), when not used for control

purposes, is available for retransmitting the PV and SP values in 0-

20 or 4-20 mA. This analog output is electrically isolated from other

inputs and outputs. The analog output signal is scalable, with the

output range defined by the values programmed in the parameters

“

rtLL

” and “

rtkL

”.

To obtain a voltage output, the user must install a resistor shunt

(550

Ω

max.) to the current output terminals (terminals 7 and 8).

The actual resistor value depends on the desired output voltage span.

SOFT-START

The soft-start feature avoids abrupt variations in the power delivered

to the load regardless of the system power demand.

This is accomplished by defining a limiting ramp for the control

output. The output is allowed to reach maximum value (100 %) only

after the time programmed in the soft-start parameter has elapsed.

The Soft-start function is generally used in processes that require slow

start-up, where the instantaneous application of 100 % of the available

power to the load may cause damages to parts of the system.

In order to disable this function, the soft-start parameter must be

configured with 0 (zero).

REMOTE SETPOINT

The controller can have its Setpoint value defined by an analog,

remotely generated signal. This feature is enabled through the

channels I/O3, I/O4 or I/O5 when configured as digital inputs and

configured with the function

rsp

(Remote SP selection) or through

the parameter

E.rsp

. The remote setpoint input accepts the signals

0-20 mA, 4-20 mA, 0-5 V and 0-10 V.

For the signals of 0-20 and 4-20 mA, a shunt resistor of 100

Ω

is

required between terminals 9 and 10, as shown in

Figure 4c

.

LBD - LOOP BREAK DETECTION

The parameter defines a time interval, in minutes, within which the

PV is expect to react to a control output signal. If the PV does not

react properly within the time interval configured in

lbd.t

, the

controller interprets this as a control loop break and signals this

occurrence in the display.

A LBD event may be sent to any I/O channel. Simply configure the

LDB

function to the desired I/O channel: the selected output will be

activated when a

LDB

condition is detected. When the

lbd.t

parameter is programmed with 0 (zero), the

LDB

function is disabled.

The

LDB

is useful in system supervision and troubleshooting, allowing

early detection of problems in the actuator, power source or load.

SAFE OUTPUT VALUE WITH SENSOR FAILURE

A function that sets the

control output 1

in a safe condition for the

process when is identified an error in the input sensor.

When the controller identifies a failure in the sensor (input), it forces

the value of MV1 applying the percentage set by the user in

parameter

1E.ov

.

If the

1E.ov

parameter is set to 0 (zero) this function will be disabled

and the control output will be simply switched off when sensor failure

occurs.

USB INTERFACE

The USB interface is used for CONFIGURING or MONITORING the

controller. The

NConfig

software must be used for the configuration.

It makes it possible to create, view, save and open configurations

from the equipment or files in your computer. The tool for saving and

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the

NConfig

software also makes it

possible to update the firmware (internal software) of the controller

through the USB.

For MONITORING purposes you can use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communications port. When connected to

the USB of a computer, the controller is recognized as a conventional

serial port (COM x). Use the

NConfig

software or consult the

DEVICE MANAGER in the Windows CONTROL PANEL to identify

the COM port that was assigned to the controller. Consult the

mapping of the MODBUS memory in the controller’s communications

manual and the documentation of your supervisory software to

conduct the MONITORING process.

Follow the procedure below to use the USB communication of the

equipment:

•

Download the

NConfig

software from our website and install it on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

•

Connect the USB cable between the equipment and the

computer. The controller does not have to be connected to a

power supply. The USB will provide enough power to operate the

communication (other equipment functions cannot operate).

•

Open the

NConfig

software, configure the communication and

start recognition of the device.

The USB interface IS NOT SEPARATE from the

signal input (PV) or the controller digital inputs and

outputs. It is intended for temporary use during

CONFIGURATION and MONITORING periods. For

the safety of people and equipment, it must only be

used when the piece of equipment is completely

disconnected from the input/output signals. Using

the USB in any other type of connection is possible

but requires a careful analysis by the person

responsible for installing it. When MONITORING for

long periods of time and with connected inputs and

outputs, we recommend using the RS485 interface,

which is available or optional in most of our products.

INSTALLATION / CONNECTIONS

The controller must be fastened on a panel, following the sequence

of steps described below:

•

Prepare a panel cut-out of 45.5 x 45.5 mm;

•

Remove the mounting clamps from the controller;

•

Insert the controller into the panel cut-out;

•

Slide the mounting clamp from the rear to a firm grip at the panel.