Operating instructiOns 8264

6

2018-09-12

operaTion

Removal of workpiece

The finished workpiece is removed from the machine as follows:

• Loosen the set screws of the bending roll so that the bending roll is

released from the workpiece.

• Remove the locking device of the clamp.

• Introduce a flat bar or similar between the bending and lower rolls a

couple of centimeters from the drive side.

• Turn the set screw on the drive side down so that the bending roll

hangs freely when the clamp is pulled down.

• Go over to the other side of the machine and adjust the set screw

until the clamp can easily be pulled down.

• Pull down the clamp and remove the workpiece.

• Raise the clamp and mount the locking device.

Cone bending

In order to be able to make cones, the machine must be equipped

with a cone bending device.

The cones are made as follows:

• Raise the cone bending device so that it rests on the bending roll

(see figure).

• Introduce the workpiece so that its rear end is parallel to the rear

lower roll and the small radius points at the cone bending device.

• Screw down the bending roll on the cone bending side so that a

bend appears (check that there is enough room for the material to

move).

• Start the bending process and let the sheet skid against the cone

bending device at the same time as it is fed through the machine

and bent.

• Screw down the bending roll somewhat. Bend again and continue

until the cone has obtained the desired form.

Содержание 8264

Страница 1: ...Bending Roll Machine 8264 Operating Instructions...

Страница 2: ......

Страница 17: ...8264 English rev 3 17 Spare parts 80 90...

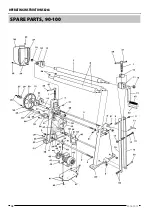

Страница 18: ...Operating Instructions 8264 18 2018 09 12 Spare parts 90 100...

Страница 19: ...8264 English rev 3 19 Spare parts 100 110...

Страница 20: ...Operating Instructions 8264 20 2018 09 12 Spare parts 120 130...

Страница 23: ......