Operating instructiOns 8264

12

2018-09-12

service and MainTenance

Installation

The machine must be placed on firm ground e.g. cemented floor. The ground must be level in order to

avoid tensions in the machine when fixing it to the floor.

Check that the motor is branched to the right voltage. Also check the direction of rotation. Plates with

“Forward” and “Reverse” are mounted on the protection cover of the foot switch.

If the machine is equipped with motor powered setting of the bending roll and/or the lower roll also

check the voltage and oil level here.

Maintenance

The machine is delivered with greased bearings for about 200 hours’ continuous duty. After this period it

should be lubricated with ball bearing grease of good quality, e.g. Esso Multi purpose grease H or equiv-

alent. All rolls and worm gears are mounted on needle and ball bearings and therefore recommended

grease should be used. Guides for the roll bearing box as well as sleeves for the bending roll and cone

bending device to be lubricated when required. Grease lubs, see grease chart.

The gearbox is lifetime lubricated and doesn’t need any regular inspection. Should there be any leakage,

please check oil level and refill if necessary.

Daily check

• Brake function of the motor

• All emergency stop functions

Содержание 8264

Страница 1: ...Bending Roll Machine 8264 Operating Instructions...

Страница 2: ......

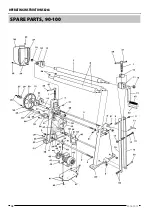

Страница 17: ...8264 English rev 3 17 Spare parts 80 90...

Страница 18: ...Operating Instructions 8264 18 2018 09 12 Spare parts 90 100...

Страница 19: ...8264 English rev 3 19 Spare parts 100 110...

Страница 20: ...Operating Instructions 8264 20 2018 09 12 Spare parts 120 130...

Страница 23: ......