30

OM944F 5/21

SP-14. CHECKING COOLANT LEVEL

1. Check the coolant level each day before starting the

engine.

a.

Check the water level by removing the pressure

cap from the expansion tank. In order to give the

cooling water an opportunity to expand, the level

should be about 1 in. (2.5 cm) below the filler cap

sealing surface when the engine is cold.

b. Soft water with about a pH about 6.5 to 8.5

combined with an antifreeze in a 30% to 50%

(maximum) solution should be used.

c. The antifreeze should not contain amine, silicate,

or borate.

SP-15. COOLING SYSTEM FLUSHING

1. Flush the cooling system every 2000 hours or every

12 months, whichever comes first.

2. Remove

fill

cap and open drains on engine block.

The engine block drain is on the service side of the

engine above the dipstick, next to the flywheel

housing.

3. Pour clean water into the engine until water coming

from engine is clear of discoloration. Close drains and

refill

the engine with recommended coolant mixture.

4. Use 50% water / 50% (maximum) ethylene glycol

antifreeze mix. Antifreeze mixture is recommended

as a good year-round coolant.

5. Coolant capacity is approximately 3 gal. (11.4 liters).

6. Check hoses and connections and repair any

leakage.

7. Start the engine and check for leaks. Run the engine

for five minutes, then shut it down. Let engine cool,

and then check the coolant level in the engine. Add

coolant as needed.

NOTE: Be sure to open the sea-cock after working

on the engine cooling system and starting the

engine.

Servicing

COOLING SYSTEM - GENERAL

NOTE: Be sure to close the sea-cock before working

on the engine cooling system.

CAUTION: The cooling water in the engine

reaches extremely high temperatures. You must use

extreme caution when working on hot engines to

avoid burns. Allow the engine to cool before

working on the cooling system. Open the filler

cap carefully, using protective clothing when the

engine is warm.

WATER QUALITY

1. Distilled, deionized, soft water is preferred for use in

cooling systems. Bottled distilled water from a food

store or water supplier is recommended. Tap water

often has a high mineral content. Tap water should

NEVER

be put in a cooling system unless first tested

by a water quality laboratory. Do not use water

made by the reverse osmosis method unless it has

been PH neutralized.

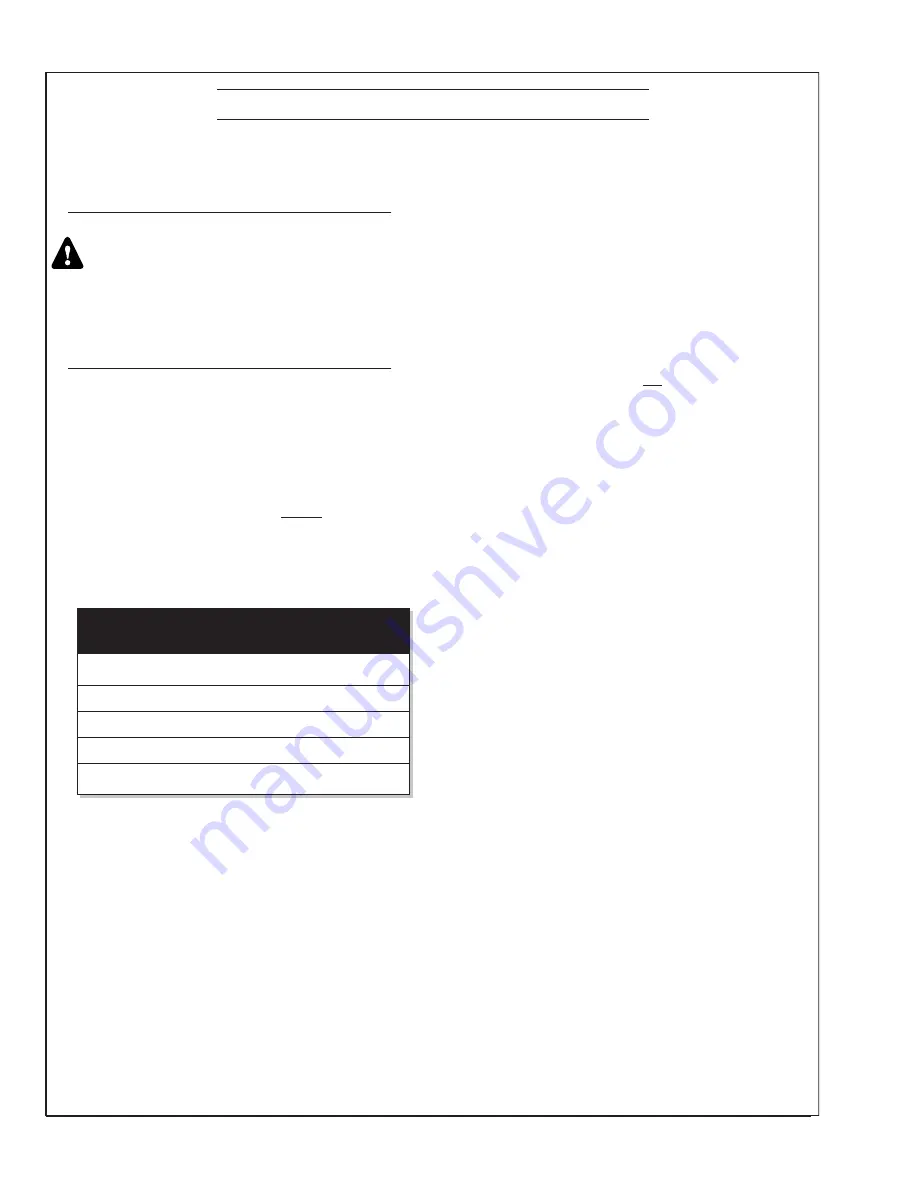

2. Here are acceptable water quality specifications:

3. If chlorides, sulfates or total dissolved solids are

higher than the above given specification, the water

must be distilled, demineralized, or

deionized before it is used in a cooling system.

4. If total hardness is higher than 170 ppm and all other

parameters are within the given specifications, the

water must be softened before it is used to make

coolant solution.

Parts Grains

Contaminates

per Million per Gallon

Maximum Chlorides

40

2.5

Maximum Sulfates

100

5.9

Maximum Dissolved Solids

340

20.0

Maximum Total Hardness

170

10.0

PH Level 5.5 to 9.0

Содержание M944T3F

Страница 70: ...68 OM944F 5 21 Panel Wiring Diagram Panel Wiring Diagram S 1 Panel B A 12798B Updated 10 16 20...

Страница 71: ...OM944F 5 21 69 NORTHERN LIGHTS Panel Wiring Diagram Panel Wiring Diagram S 1B B Deutsch A 12791C...

Страница 72: ...70 OM944F 5 21 NORTHERN LIGHTS Panel Wiring Diagram Panel Wiring Diagram S 3B S 3C Panel B A 12790D...

Страница 73: ...OM944F 5 21 71 Panel Wiring Diagram S 3A B Deutsch B 10854D Panel Wiring Diagram Updated 3 31 21...

Страница 75: ...OM944F 5 21 73 NON CURRENT MODEL AC Wiring Diagram AC Wiring Diagram M944W3 and M30CW3 12 wire B 9723D...

Страница 79: ...OM944F 5 21 77 DC Wiring Diagram DC Wiring Diagram M944W3 24 VDC Isolated Ground C 6871A NON CURRENT MODEL...

Страница 83: ......