26

OM944F 5/21

SP-10. BLEEDING THE FUEL SYSTEM

CAUTION: Escaping diesel fuel under

pressure can penetrate skin causing serious

personal injury. Before disconnecting lines be

sure to relieve all pressure. Before applying

pressure, be sure all connections are tight and

lines, pipes and hoses aren't damaged. Fuel

escaping from a very small hole can be almost

invisible. Use a piece of cardboard or wood,

rather than hands, to search for suspected

leaks. If injured by escaping fuel, see a doctor

at once. Serious infection or reaction can

develop if proper medical treatment is not

administered immediately.

1. Fuel system air bleeding may be needed when:

a. After fuel has been added to a newly installed

engine.

b. A new fuel filter is installed.

c. The engine has run out of fuel.

d. The fuel lines, injection pump, or any other fuel

system component has been removed and

installed.

2. After changing the fuel filter, air only needs to be

bled from the fuel filter.

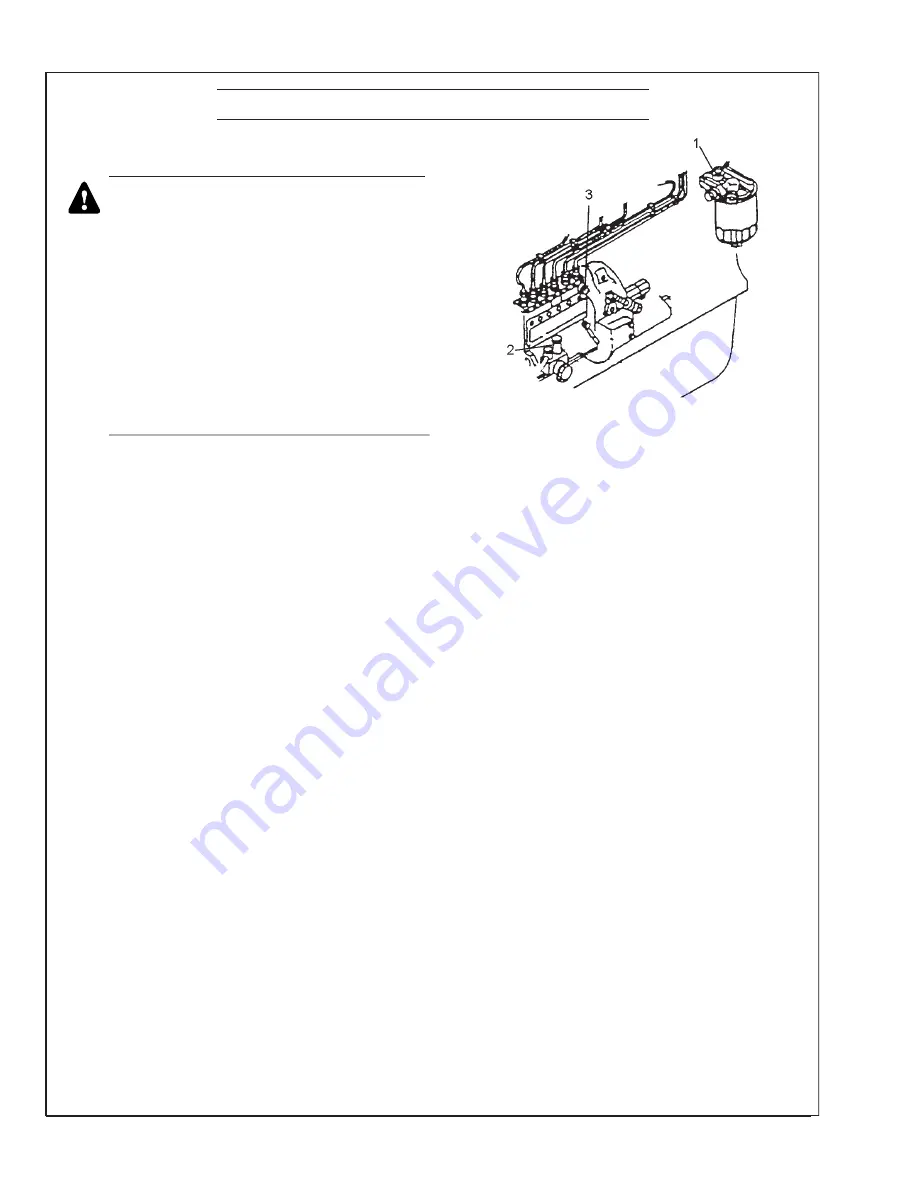

a. Loosen the air vent plug

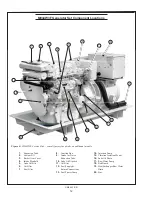

(#1 on Figure 10)

on the

fuel filter by about 1-1/2 turns. (Be sure to cover

the vent with a cloth to prevent fuel from

splashing.)

b. Turn the priming pump cap on the fuel feed pump

counterclockwise to unlatch it. Move the priming

pump plunger

(#2 on Figure 10)

up and down. To

close the pump turn the cap clockwise while

depressing it.

c. Close the air vent plug when no more air bubbles

can be seen in the fuel flowing from the air vent

plug hole.

Servicing

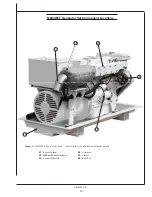

Figure 13:

Fuel Feed Pump

3. To bleed air at the fuel injection pump:

a. Turn the air vent plug

(#3 on Figure 10)

about

1-1/2 turns to loosen it. (Cover the vent with a

cloth to prevent fuel from splashing.)

b. Pump the feed pump cap up and down.

c. When there are no air bubbles to be seen in the

fuel flowing from the air vent plug hole, push

down the priming pump cap and turn it clockwise

to lock it in place.

NOTE:

Do not close the air vent plug before locking the

priming pump cap in place, because the internal

pressure in the pump will prevent the priming

pump cap from returning to the original

position.

4. If the engine does not start after this bleeding

process, loosen a fuel line at the injector while

cranking the engine with the starter motor until pure

fuel escapes. Then tighten the connections. Do each

line one-at-a-time. After the engine has started, use

a piece of cardboard to look for fuel leaks.

Содержание M944T3F

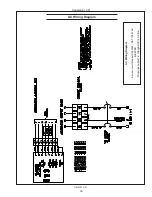

Страница 70: ...68 OM944F 5 21 Panel Wiring Diagram Panel Wiring Diagram S 1 Panel B A 12798B Updated 10 16 20...

Страница 71: ...OM944F 5 21 69 NORTHERN LIGHTS Panel Wiring Diagram Panel Wiring Diagram S 1B B Deutsch A 12791C...

Страница 72: ...70 OM944F 5 21 NORTHERN LIGHTS Panel Wiring Diagram Panel Wiring Diagram S 3B S 3C Panel B A 12790D...

Страница 73: ...OM944F 5 21 71 Panel Wiring Diagram S 3A B Deutsch B 10854D Panel Wiring Diagram Updated 3 31 21...

Страница 75: ...OM944F 5 21 73 NON CURRENT MODEL AC Wiring Diagram AC Wiring Diagram M944W3 and M30CW3 12 wire B 9723D...

Страница 79: ...OM944F 5 21 77 DC Wiring Diagram DC Wiring Diagram M944W3 24 VDC Isolated Ground C 6871A NON CURRENT MODEL...

Страница 83: ......