59

EN

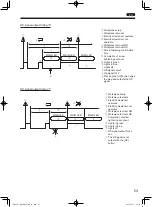

Forced stop signal

CAUTION

z

z

When the force stop signal is used, the link function cannot be used.

z

z

Make sure to connect an external power supply.

z

z

For connection, use thick wire as much as possible. (AWG20 or more is recommended)

z

z

For connection of an external signal, use a commercially available terminal block.

z

z

A 2-wire sensor cannot be used.

A 2-wire sensor has a flow of fine current even while OFF, and could cause a malfunction.

z

z

For the sensor, use a PNP output type 3-wire sensor.

z

z

Depending on the sensor installation environment, a malfunction could occur due to noise.

Make sure to take sufficient noise measures such as setting up grounding. For details, read the instruction

manual of the sensor to be used.

You can forcefully stop operation of an electric screwdriver externally. Forced stop signal allows you to control

operation without turning off the electric screwdriver.

You can add conditions by combining workpiece signals, for example, place workpiece (workpiece signal ON, forced

stop signal ON) → remove workpiece (workpiece signal ON, forced stop signal OFF) → operate electric screwdriver.

Forced stop signal input turns ON and the electric screwdriver is stopped forcefully and then the workpiece LED goes

off.

The forced stop signal input turns OFF and the electric screwdriver starts operating and then the workpiece LED lights

in green.

1

Connect the I/O signal

Connection example

Connected signal

Pin No.

Signal cable (sold separately) wiring color

+24 DC power

1

Red

Forced stop

signal

4

Yellow

0 VDC

12

Black

2

Press and hold the [MEMORY] button and [SELECT] button

The mode enters function setting mode.

3

Press the [SELECT] button to select function No. 14

4

Use the [UP] or [DOWN] button to set pin No. 4 input switching to “0: Forced stop signal”

5

Press and hold the [MEMORY] button to save the setting

TV07521-1_DLV30S12P-AYK_en.indb 59

2017/02/10 15:56:38