38

- FORM NO. 56043122 - BR 1100S, 1300S

6 - WHEEL DRIVE SYSTEM

16 15 14 13 12 11 10 9

8 7 6 5 4 3 2 1

AUXILIARY

MOTION

DRIVER

FAULT

1

THROTTLE

CONTROL

WIPER

MAIN

CONTACTOR

DRIVER

MODE 1

SELECT

INTERLOCK

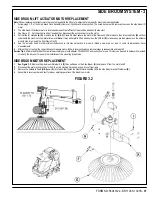

Detail of A1 16-pin connector, as shown in Figure 6.1

Used (11 Pins)

Not Used (5 Pins)

KEY SWITCH

INPUT (KSI)

MODE 2

SELECT

AUXILIARY

DIRECTION

DRIVER

POT LOW

POT HIGH

GENERAL FUNCTIONAL OVERVIEW

A 1.75 HP separately excited (

fi

eld & armature) 36V DC motor/gear/wheel unit (M1) is used to propel the machine. A Curtis model 1243 PMC solid state speed

controller (A1) regulates (outputs) the variable speed Fwd/Rev wheel drive motor functions. The controller unit is located to the left of the operator seat, behind the

electrical access panel. The electrical potentiometer R1 mounted to the operator foot pedal inputs to the (A1) controller the machine operator’s speci

fi

c speed and

direction demands.

DRIVE MOTOR SYSTEM CONTROLLER FUNCTION OVERVIEW

See Figure 6.1. To make the A1 speed controller’s internal circuits operational (power it up) the two switches S1, main power and S2 charger interlock must be

closed. Next the seat switch S3 must be depressed for the main contactor K7 to be energized. Depressing the foot pedal in either Fwd or Rev will move the R1

potentiometer and provide the needed direction and 0-5V throttle input signals for controller output. These controller inputs direction and voltage then energize the

internal transistors which selects the motor polarity and also at the same time manages the current and voltage output values to the two separate motor circuits

(armature &

fi

eld) per the percentage of the R1 throttle movement.

MOTOR OPERATION

The motor has (4) terminal connections, (2) armature A1, A2 and (2)

fi

eld F1, F2. The motor armature circuit receives from the controller a chopped on time off time

*PWM voltage and current output that varies the motor speed. The

fi

eld circuit sees the current direction polarity change that effects the rotation of the motor CW

for FWD and CCW for REV.

DRIVE WHEEL SYSTEM SPEEDS

The speed controller is programmed for two maximum speed setting modes, M1max and M2max. The M1max is the transport speed mode and is set at 100% of the

total systems speed potential. The M2max is the scrubbing speed mode and is set at 70% of the total system’s speed potential.

Note:

Both of the speed settings

(M1 & M2) can be changed (increased or decreased) from the original factory speci

fi

cations only by using the hand held programmer PN 56409441. See in the

Electrical System of this manual instructions for using the programmer for speed setting changes and troubleshooting diagnostics.

*PWM; pulse width modulation, also called “chopping” is a technique that switches battery voltage to the motor ON and OFF very quickly, thereby controlling the

speed of the motor.

Содержание 56413006

Страница 7: ...FORM NO 56043122 BR 1100S 1300S 5 SPECIFICATIONS ...

Страница 9: ...FORM NO 56043122 BR 1100S 1300S 7 FIGURE 1 ...

Страница 10: ...8 FORM NO 56043122 BR 1100S 1300S THIS PAGE INTENTIONALLY BLANK ...

Страница 36: ...34 FORM NO 56043122 BR 1100S 1300S 4 RECOVERY SYSTEM FIGURE 4 2 ...

Страница 39: ...FORM NO 56043122 BR 1100S 1300S 37 SQUEEGEE SYSTEM 5 FIGURE 5 2 ...

Страница 47: ...FORM NO 56043122 BR 1100S 1300S 45 WHEEL DRIVE SYSTEM 6 FIGURE 6 5 ...

Страница 53: ...FORM NO 56043122 BR 1100S 1300S 51 REAR WHEEL SYSTEM 7 FIGURE 7 3 ...

Страница 61: ...FORM NO 56043122 BR 1100S 1300S 59 ELECTRICAL SYSTEM 8 J Ø 4 K Fault Indicator 03 FIGURE 8 7 ...