Electrical System

54

Service Manual – SC1500

Troubleshooting

Note:

Refer to the individual machine system sections for electrical troubleshooting procedures.

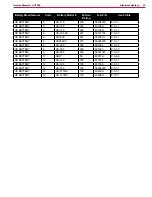

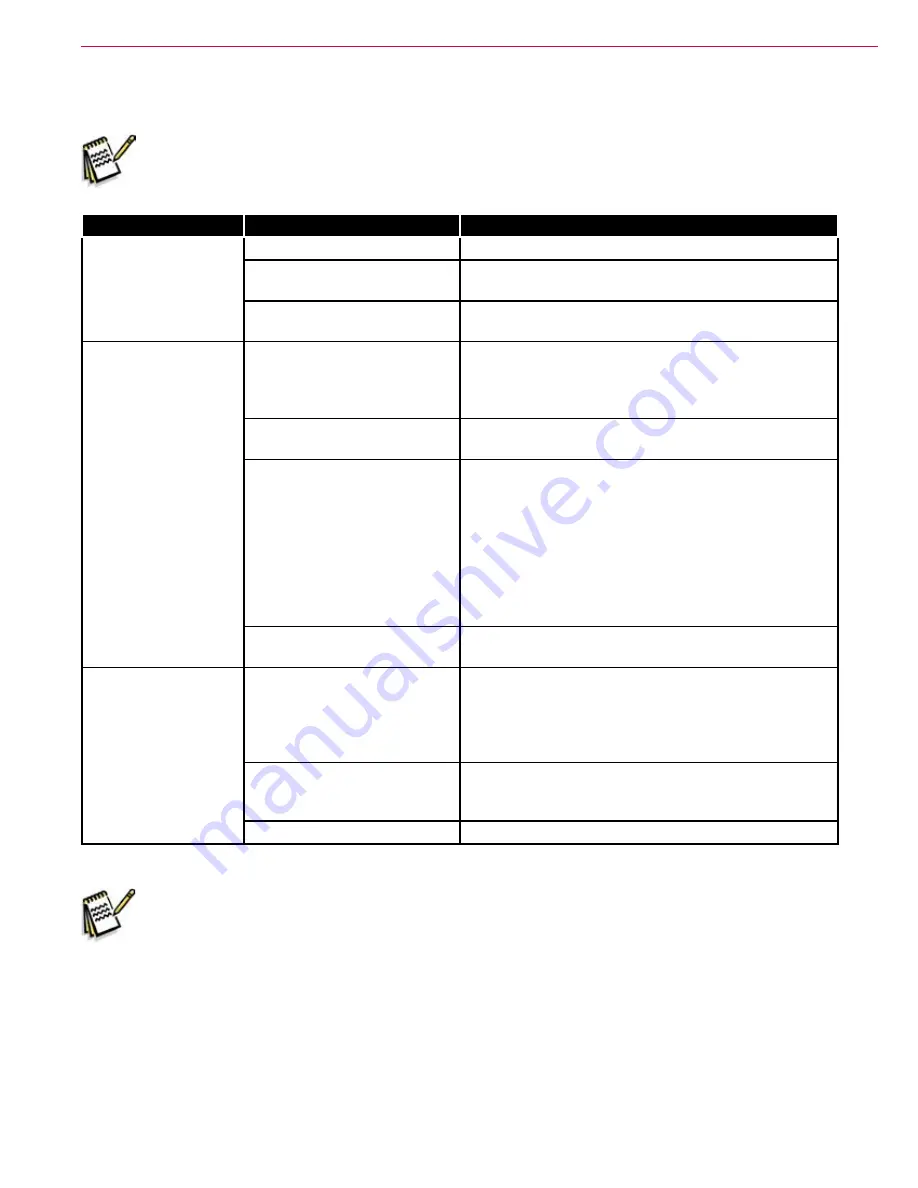

Problem

Cause

Correction

No power to the

machine.

Discharged batteries.

Check the battery voltage and charge as necessary.

Poor battery connection(s).

Check the battery cables, terminals and connections

and tighten/repair/replace as necessary.

Batteries need to be replaced.

Perform a load test on the batteries and replace if

necessary.

Insufficient machine

run time.

Incorrect low-voltage cutout

setting.

Make sure the low battery voltage cutout setting is

correct for the battery type in the machine. (Refer to

the Control System/Programming Options/Low Battery

Voltage Cutout subsection.)

Batteries not fully charged.

If there is any question whether the batteries are fully

charged, they should be charged for at least 16 hours.

One or more weak batteries.

•

Measure the voltage across each individual battery

while operating the machine. Write down the values

and compare them. A battery that has a dead cell will

typically be 1 - 2 volts lower than the others.

•

Use a battery load tester to test each battery.

•

For wet batteries, a hydrometer can be used to

check the specific gravity of the electrolyte in each

cell. A dead cell is one that reads 50 points or more

lower than the other cells.

Poor battery connection(s).

Check the battery cables, terminals and connections

and tighten/repair/replace as necessary.

The battery charger

does not charge.

Battery charger not operating

correctly.

1. Check the charger 120VAC power cord and

power source to the charger and repair as

necessary.

2. If the electrical connections are OK, replace the

charger.

There’s a problem with

the charger wiring and/or

connections.

Check the charger connections to the machine and

repair as necessary.

One or more weak batteries

Check and replace the batteries as necessary.

Note:

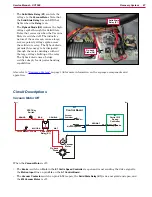

The optional S.P.E. on-board battery charger will charge, even if it cannot communicate with the A1

Control Board.