8 - TROUBLESHOOTING

Hydrostatic transmission - Troubleshooting

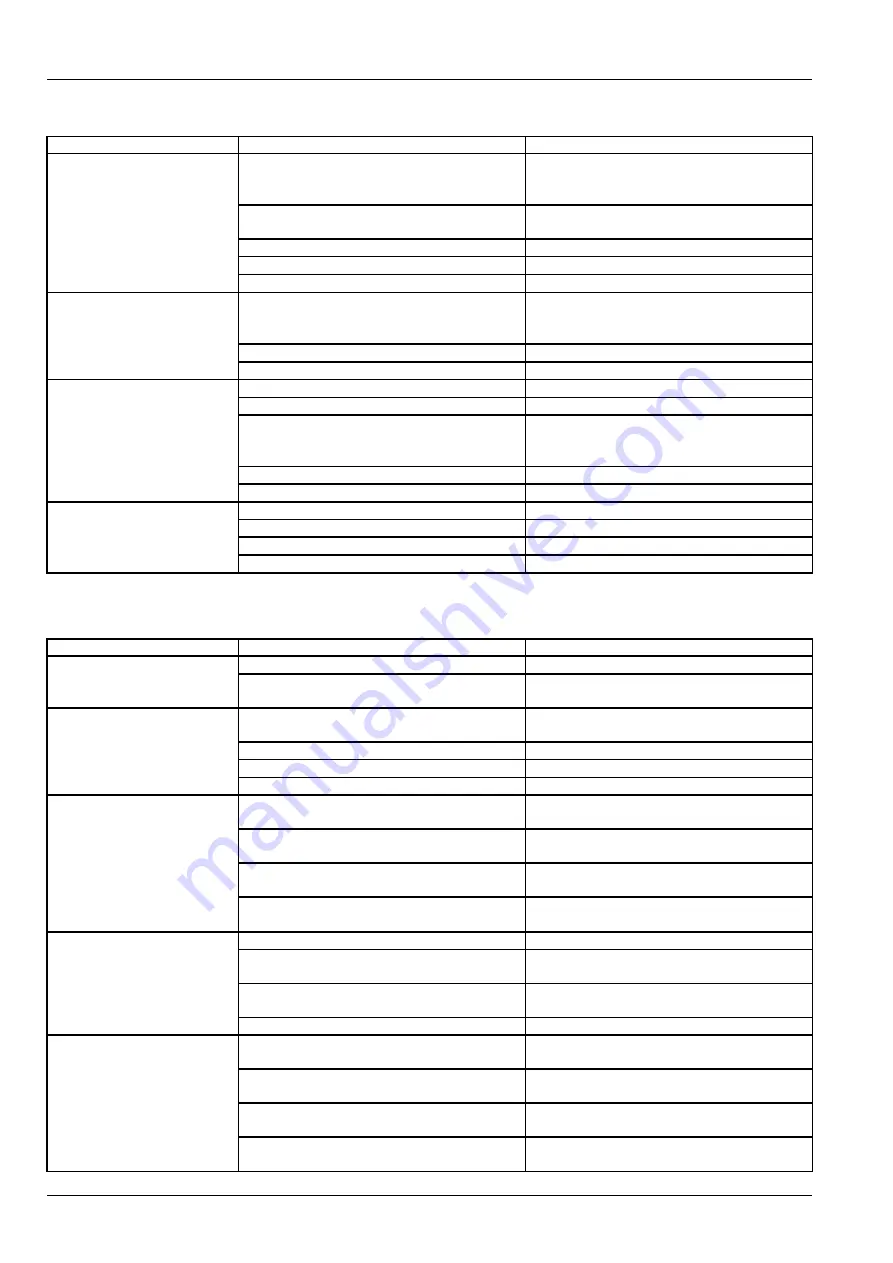

Problem

Possible Cause

Correction

When operating HST

pedal, tractor does not

move.

HST high pressure relief valve pressure

setting low

Check HST pressure and repair as needed

HST charge pressure valve faulty

Check HST charge pressure and repair as

needed

HST Filter clogged

Replace HST filter

HST pump faulty

Repair or replace HST pump

HST control linkage worn or damaged

Repair or replace linkage as needed

Tractor is still moving

when HST pedal is in

neutral position

Incorrect neutral adjustment of HST linkage Adjust neutral position of HST linkage

HST pedal linkage damaged

Replace damaged linkage parts as needed

HST control arm clamp bolt loose

Tighten control arm clamp bolt

HST power is low

Oil shortage

Add transmission oil as needed

Air in HST circuit

Check and repair the hydraulic suction line

Transmission oil temperature is too high

Shut down tractor to cool the transmission

oil, and restart after oil temperature has

been reduced

HST internal parts worn

Repair HST transmission as needed

HST filter clogged

Replace the HST filter

Abnormal noise

Engine speed is too low

Set engine speed over

1500 RPM

Oil temperature is too low

Run engine to warm up the oil

HST oil filter clogged

Replace the HST filter

Oil shortage

Add transmission oil as needed

Electrical system - Troubleshooting

Problem

Possible Cause

Correction

Headlights are dim

Battery charge is low

Charge or replace battery

Faulty headlight wiring or faulty ground

connection

Check and repair wiring as needed

Battery does not charge

Incorrect wiring

Check battery terminals and ground for cor-

rosion

Faulty Alternator

Test alternator repair or replace as needed

Incorrect fan belt tension or broken belt

Adjust fan belt tension or replace belt

Faulty battery

Replace battery

Headlights will not

illuminate

Light bulb burnt out

Replace bulb as needed

Blown Fuse

Check the cause and replace fuse with cor-

rect size

Faulty wiring connection

Check headlight wiring connection, repair

as needed

Faulty light switch

Check switch for proper function and re-

place if needed

Horn does not sound

Horn switch failure

Replace horn switch

Faulty wiring connection

Check horn wiring connection, repair as

needed

Blown fuse

Check for cause, replace fuse with correct

size

Faulty horn

Check horn , replace if needed

Turn signal lights do not

work

Light bulb burnt out

Replace bulb, with correct size

Faulty wiring connection

Check

wiring

connections,

repair

as

needed

Blown fuse

Check the cause, replace fuse with correct

size

Faulty turn signal switch

Check switch for proper function, replace

switch if needed

8-4

Содержание Workmaster 25 Tier 4B

Страница 74: ...3 CONTROLS AND INSTRUMENTS 3 28 ...

Страница 102: ...4 OPERATING INSTRUCTIONS 5 Engage the park brake 7 and release the brake ped als slowly NHIL12CT00691AA 6 4 28 ...

Страница 110: ...5 TRANSPORT OPERATIONS 5 8 ...

Страница 116: ...6 WORKING OPERATIONS 6 6 ...

Страница 155: ...7 MAINTENANCE NOTE Approximate fluid capacity for the front axle housing is 5 5 l 5 8 US qt 7 39 ...

Страница 158: ...7 MAINTENANCE Valves Check Contact your NEW HOLLAND dealer to schedule this service for your tractor 7 42 ...

Страница 178: ...8 TROUBLESHOOTING 8 6 ...

Страница 187: ...9 SPECIFICATIONS NHIL12CT00862HA 1 9 9 ...

Страница 188: ...9 SPECIFICATIONS 9 10 ...

Страница 190: ...10 ACCESSORIES 10 2 ...