M1.1.TPT1300-TPT2000.NLFREN 08122017

11

NL

4. Duw de motor naar de achterkant van de plaat

door de instelbouten A te draaien, om de speling

van de riemen te elimineren.

Controleer bij de instelling van de riem

en dat het riemschijf van de koppeling

met dit van de excitator uitgelijnd is.

5. Wanneer de riemspanning correct is, draai de

moeren B tegen de beugel terug aan.

6. Draai de montagebouten van de motor terug aan.

7. Plaats het riemdeksel terug.

Als een riem niet meer ingesteld kan worden,

moet deze vervangen worden.

3. Draai de moeren B los, door voldoende ruimte

tussen de moeren en de beugel te laten.

PLATE COMPACTOR

13

GB

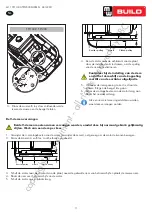

When adjusting the belt(s), make

sure that the clutch pulley is in

alignment with exciter pulley.

Loosen the jam nuts B, leaving enough

space between the nut and bracket.

When the V-belt tension is correct, tighten

the jam nuts B against the bracket.

Tighten the engine mount bolts.

Replace the belt guard.

Push engine toward the back of the plate

by turning the adjustment bolts A to

remove any slack in V-belt(s).

Remove the metal cover or water tank.

Loosen 4 engine mount bolts (do not

remove) only enough to move the engine

forward.

3.

5.

4.

1.

2.

6.

7.

V-belt

Clutch pulley

Exciter pulley

If the adjustment bolts have no

more adjustment left, the belt(s)

may have to be replaced.

Compactor with optional water sprinkler kit

29242 / 29255 / 29260 / 29265

29240

A

B

A

A

B

B

29242UK00M101-改.indd 13

2016/6/23 17:58:38

PLATE COMPACTOR

13

GB

When adjusting the belt(s), make

sure that the clutch pulley is in

alignment with exciter pulley.

Loosen the jam nuts B, leaving enough

space between the nut and bracket.

When the V-belt tension is correct, tighten

the jam nuts B against the bracket.

Tighten the engine mount bolts.

Replace the belt guard.

Push engine toward the back of the plate

by turning the adjustment bolts A to

remove any slack in V-belt(s).

Remove the metal cover or water tank.

Loosen 4 engine mount bolts (do not

remove) only enough to move the engine

forward.

3.

5.

4.

1.

2.

6.

7.

V-belt

Clutch pulley

Exciter pulley

If the adjustment bolts have no

more adjustment left, the belt(s)

may have to be replaced.

Compactor with optional water sprinkler kit

29242 / 29255 / 29260 / 29265

29240

A

B

A

A

B

B

29242UK00M101-改.indd 13

2016/6/23 17:58:38

TPT1300 - TPT200

De V-riemen vervangen

Beide V-riemen moeten samen vervangen worden, omdat deze bij normaal gebruik gelijkmatig

slijten. Werk aan een riem per keer.

1. Verwijder de 4 montagebouten van de motor (verwijder deze niet), net genoeg om de motor te kunnen bewegen.

2. Draai de moeren A en B los, zoal hierboven afgebeeld.

11

Vibratory Plate Compactor

Turn off engine. Engine must be cool.

Remove the belt guard to access the V-belt(s).

Check the condition of the V-belt(s). If any V-

belt is cracked, frayed, or glazed, it should be

replaced as soon as convenient.

Check the V-belt tension by squeezing them in

the center. The normal deflection on each side

should be 9mm (3/8”) to 13mm (1/2”) with

moderate pressure from your thumb or finger.

1.

2.

3.

4.

Tensioning V-Belt(s)

Loosen 4 engine mount bolts (do not remove)

only enough to move the engine forward.

Proper belt tension is critical to good performance.

Proper adjustment will assure long belt life. Too

much or too little belt tension will cause premature

belt failure.

1.

When the V-belt tension is correct, tighten the

jam nuts

B

against the bracket.

Tighten the engine mount bolts.

Replace the belt guard.

4.

5.

6.

If the adjustment bolts have no more

adjustment left, the belt(s) may have to

be replaced.

Replacing V-Belt(s)

For #29142 & #29155, both V-belts should

be replaced at the same time because they

will wear evenly through normal use. Work

on one belt at a time.

Loose 4 engine mount bolts (do not remove)

only enough to move the engine forward.

Loosen the jam nuts

B

and bolts

A

shown in

above figure.

Slide the engine toward the front of plate and

slip the old V-belt(s) off of the wheel pulley and

install the new V-belt(s) in their place.

Position the V-belt(s) over the engine pulley.

Move the engine back.

1.

2.

3.

4.

5.

6.

Replace the belt guard.

7.

A

B

On new machines or after installing a

new belt, check belt tension after first

20 hours of operation. Check and adjust

belt every 50 hours thereafter.

When adjusting the belt(s), make sure

that the clutch pulley is in alignment

with exciter pulley.

When adjusting the belt(s), make sure

that the clutch pulley is in alignment

with exciter pulley.

When the V-belt tension is correct, tighten the

jam nuts

B

and the engine mount bolts.

V-belt

Clutch pulley

Exciter pulley

V-belt

Clutch pulley

Exciter pulley

Loosen the jam nuts

B

, leaving enough space

between the nut and bracket.

Push engine toward the back of the plate by

turning the adjustment bolts

A

to remove any

slack in V-belt(s).

2.

3.

3. Schuif de motor naar de voorkant van de plaat, neem de gebruikte riem van het riemschijf en plaats de nieuwe riem.

4. Plaats de riem over het riemschijf van de motor.

5. Schuif de motor op zijn plaats terug.

copyrighted

document

- all

rights

reserved

by

FBC