Hand Extruder MEK-32 / MAK-32

Page 18/20

Issue 12.2009/Rev. 02

MUNSCH Kunststoff-Schweißtechnik GmbH

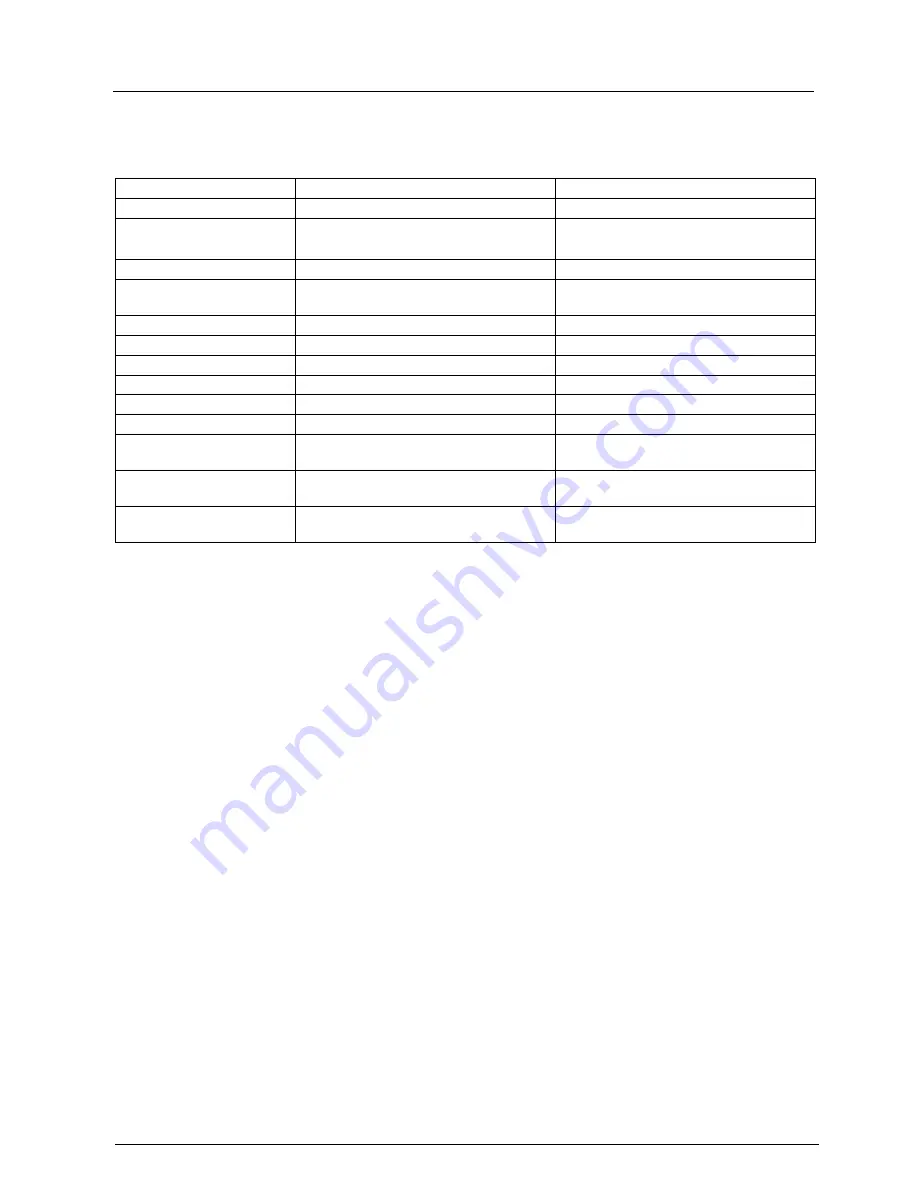

8 Technical Data

Type designation

MEK

MAK

Welding materials

PP, PE, PVDF

PP, PE, PVDF

Welding rate, approx.

32 =

∅

3 mm: 1.8 kg/h PP/PE

32 =

∅

4 mm: 3.2 kg/h PP/PE

32 =

∅

3 mm: 1.8 kg/h PP/PE

32 =

∅

4 mm: 3.2 kg/h PP/PE

Welding rod

Welding rod

∅

3 and 4 mm

Welding rod

∅

3 and 4 mm

Application range

32 = Wall thicknesses 8-30 mm and

film/sheeting welds

32 = Wall thicknesses 8-30 mm and

film/sheeting welds

Weight

32 = 7.6 kg

32 = 7.8 kg

Drive

230 V AC with speed control

230 V AC with speed control

Extruder heating system 32 = 650 W / 230 V

32 = 650 W / 230 V

Air preheater

2100 W / 230 V

2300 W / 230 V

Air supply

External air source

Integrated air supply

Air rate

300 l/min at 0.4 bar

------------

Control of melt

temperature

Temperature controller with concurrent

momentary value and setpoint display

Temperature controller with concurrent

momentary value and setpoint display

Control of air

temperature

Temperature controller with concurrent

momentary value and setpoint display

Temperature controller with concurrent

momentary value and setpoint display

Cold start protection

Start temperature interlock and startup

timer for melt and preheat air

Start temperature interlock and startup

timer for melt and preheat air

Содержание MAK-32

Страница 13: ...MEK 32 MAK 32 Issue 12 2009 Rev 02 Page 13 20...

Страница 15: ...MEK 32 MAK 32 Issue 12 2009 Rev 02 Page 15 20...