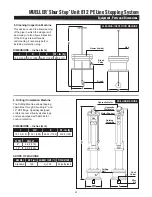

3. Attach the inserting tool and plug

onto the plug holder support and

tighten the spring detents (

C.

).

4. Lubricate the O-ring of the internal

plug with PURITY-FG Spray or

equivalent and retract the plug into

the machine adapter.

5. Assemble the completion machine

on the slide gate valve, open the

equalization valve and then open the

slide gate valve.

6. Turn the feed screw clockwise

and move the completion plug

towards the fitting.

7. Install the ratchet handle (

D.

).

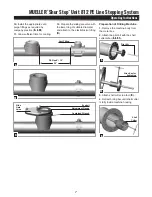

8. Fully tighten the completion plug,

taking care to SIMULTANEOUSLY

turn both the ratchet and the lead

screw clockwise.

9. Bleed any residual pressure off

using the bleed valve (see point 38

on page 9) and check the completion

plug for leaks.

MUELLER

®

Shur Stop

TM

Unit 812 PE Line Stopping System

Operating Instructions

12

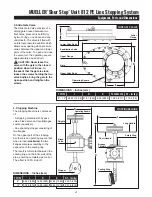

Preparation of Drilling Machine

To Insert Completion Plug

1. Attach completion plug holder

support to the drilling machine shaft

(

A. & A1.

).

2. Place the plug holder flange on

the completion plug and attach it

with the provided screws (

B.

).

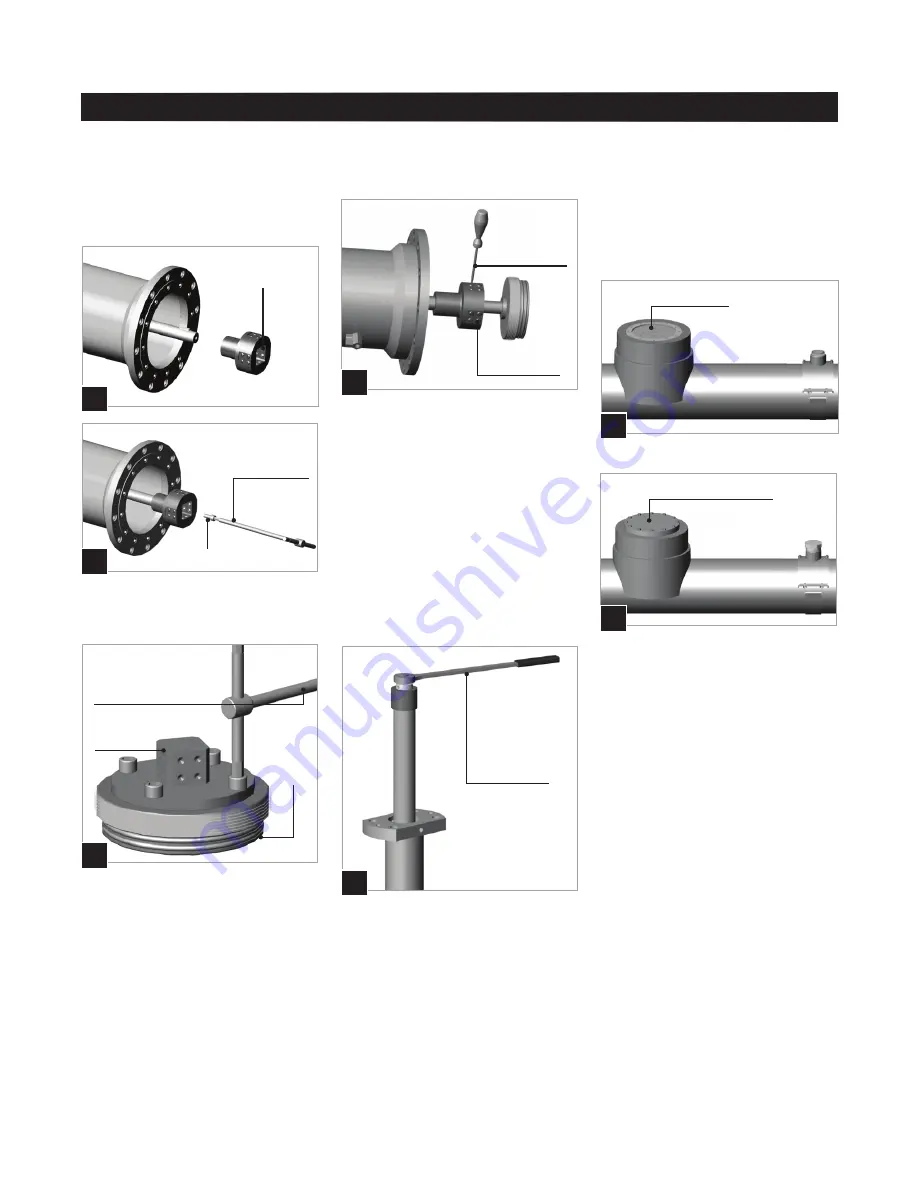

10. Remove the ratchet and turn the

feed screw of the machine counter-

clockwise until the shaft is released

from the plug holder support.

11. Remove the completion

machine, the slide gate valve and

the plug holder support (

e.

).

12. Install completion cap (

F.

).

A.

Plug Holder

Support

C.

Screwdriver

to tighten

the Spring

Detents

Spring

Detents

D.

3

/

4

ʺ Ratchet

Spanner

e.

Internal Plug

A1.

Allen Screws

Allen Key to

Tighten Allen

Screws

B.

Allen Key for tightening

Allen Screws

Plug Holder

Flange

Completion

Plug

F.

Completion Cap