12

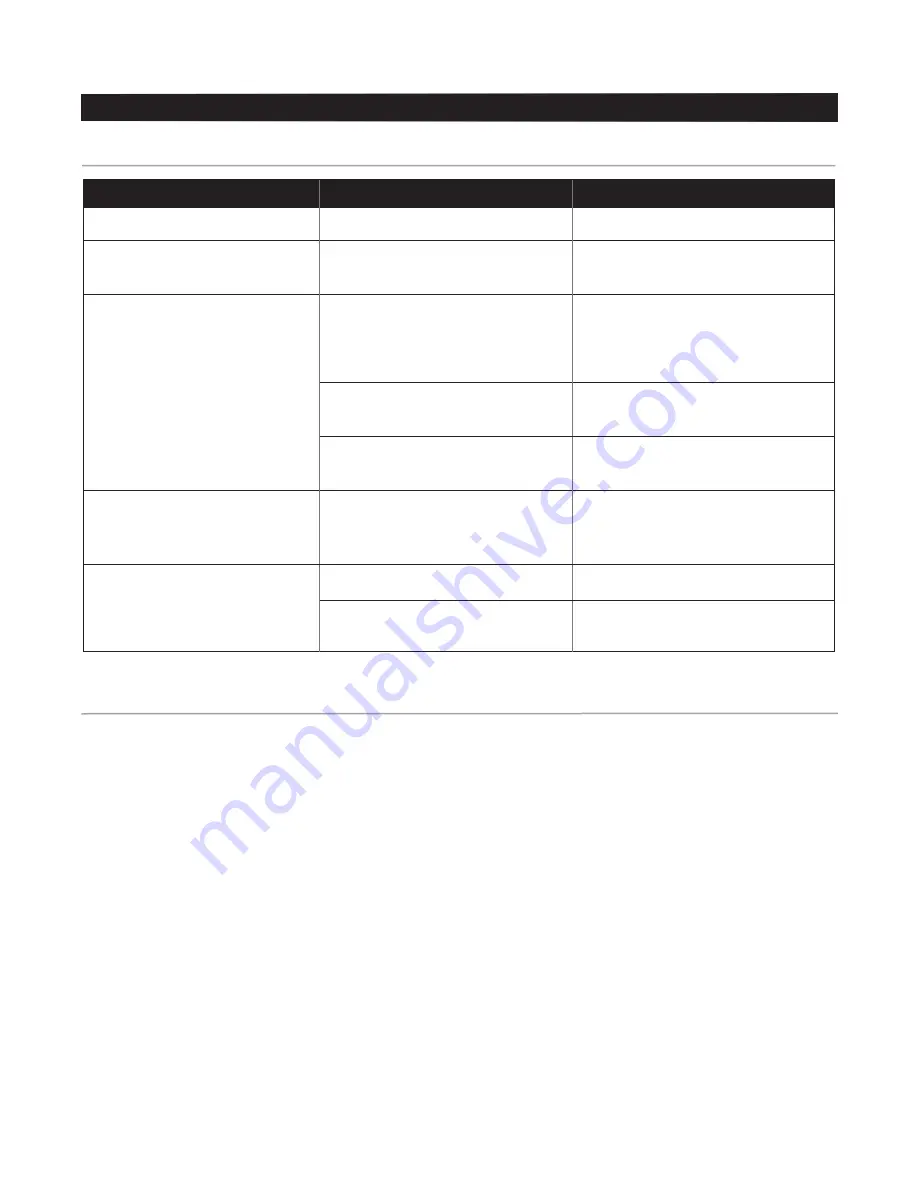

proBlem

Cause

solution

Drilling time too long

Worn cutter

Replace the cutter.

Gas leakage between the

drilling shaft and the screw

Worn O-rings

Replace the O-rings.

Inadequate sealing of the stopper No lubrication performed on the

With PURITY-FG Spray or equivalent

angled walls of the sealing ring

lubricate the angled walls of the

sealing ring expanding and retracting

it completely.

No lubrication performed on the

Lubricate the sealing disk with

sealing disk of the plug bell

PURITY-FG Spray or equivalent.

Presence of residue on the bottom Clean again using the

of the pipe

inspection / cleaning machine.

Inadequate sealing of the

Insufficient tightening of the screws

sealing disk

of the flange that compresses the

Tighten the screws slightly.

sealing disk

Inadequate sealing of the valve

Equalization valve not closed

Close the equalization valve.

Residues on the sealing O-ring

Replace the O-rings before the

next use.

MUELLER

®

Shur Stop

TM

Unit 812 PE Line Stopping System

Diagnostics / Storage

13

TrOUBLeshOOTiNG

• Store the equipment in a closed

place.

• Protect the equipment from

humidity and extreme temperature

changes.

In case of long periods of inactivity,

the equipment must be stored taking

suitable precautions for the place it

is stored in and the duration of the

storage:

• Prevent corrosive substance

from coming into contact with the

equipment.

sTOrAGe