MUELLER

®

Shur Stop

TM

Unit 812 PE Line Stopping System

Operating Instructions

10

11

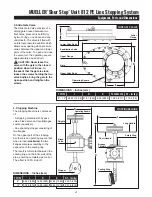

33. Carry out the cleaning operation

using the cleaning inspection

machine equipped with nylon wire

brush (

N.

).

34. Proceed with stopping operation.

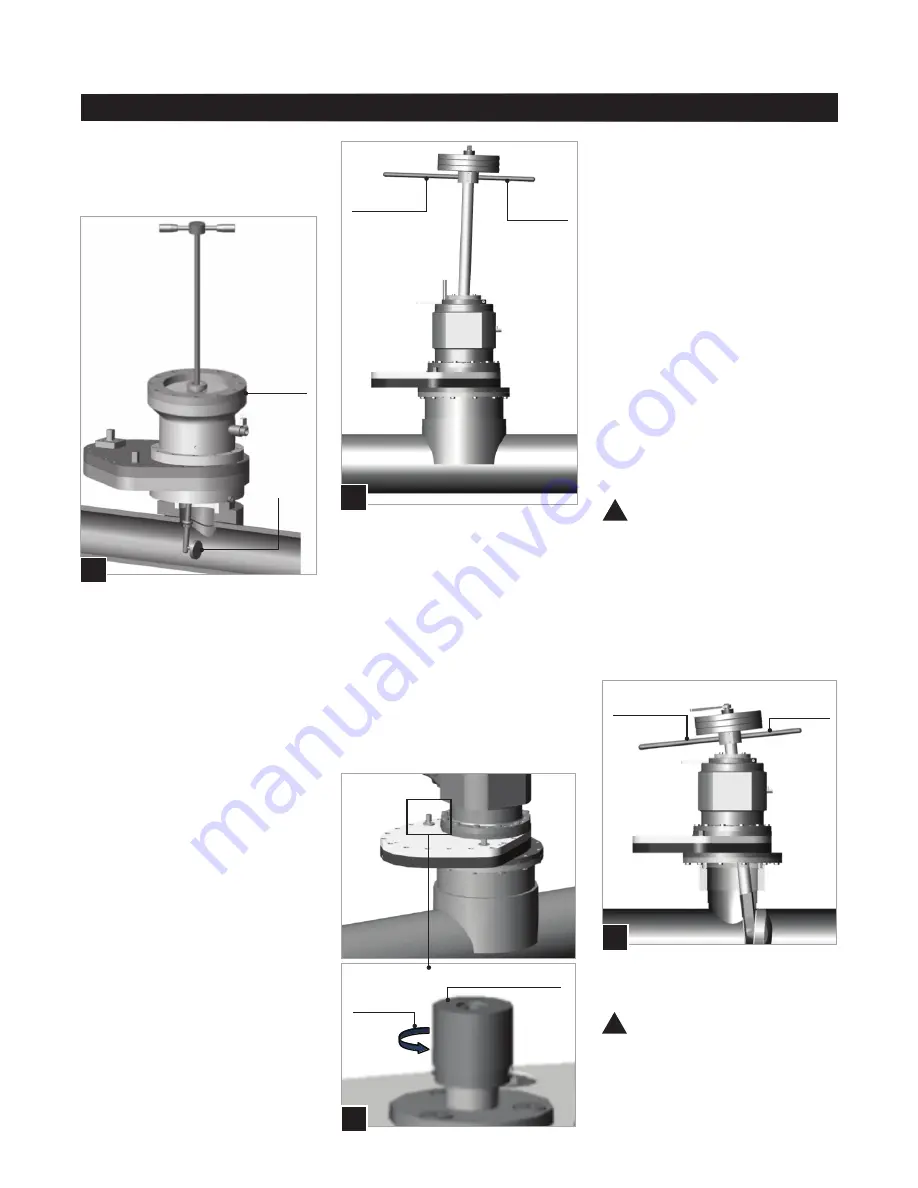

35. Check the operation of the

expanding stopper. If the sealing

ring does not expand evenly on

the entire perimeter, it is necessary

to lubricate the walls surrounding

the ring with PURITY-FG Spray or

equivalent (walls are compressed

by two steel flanges). Expand and

retract the sealing ring a few times

until the expansion is uniform. In the

event that the stopper is not used

for a long time, it is recommended to

completely disassemble the stopper,

replace the sealing ring and lubricate

thoroughly. After reassembling the

stopper, wipe the outer side of the

ring that comes into contact with the

inner side of the pipe.

36. Clean and lubricate the stopper

bar and the sealing disk to provide

smooth operation and to allow

centering of the stopper during the

expansion phase.

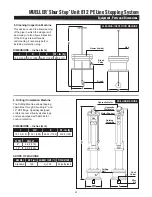

37. Position the stopping machine

(

O.

) on the slide gate valve.

NOTE: There are 2 handles on the

stopping machine. The longer one

should always be on the upstream

side.

P.

Equalization Valve

Counter-

clockwise

42. Purge the air in the bypass

through the drain valve located on

the downstream stopping machine.

43. Open the second slide gate

valve without acting on the internal

pressure equalizer, as pressure is

already equal above and below the

gate.

44. Ensure the proper operation of

the bypass and check for leaks.

45. Leaving the safety ring loose,

lower the stopper and position the

long handle between the pins on the

saftey ring. If this is difficult, repeat

previous step taking care to ensure

the plug is at a 90° position with

respect to the pipe axis. Once the

hole has been passed, place the

plug in the direction of the pipe axis.

CAUTIoN: The plug should

never be inserted and expanded

on the upstream side.

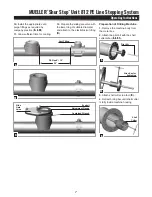

46. Turn the ratchet handle

clockwise and gradually expand the

sealing ring of the stopper. During

this operation slide the rod from top

to bottom and vice versa to properly

position the stopper in the pipe (

Q.

).

47. Expand the sealing ring to

obtain a positive shut-off. DO NOT

overtighten.

CAUTIoN: The torque applied

to the ratchet spanner should not

exceed 52 ft-lb for the 8" plug.

The torque applied to the ratchet

spanner should not exceed 74 ft-lb

for the 12" plug.

38. Perform the same operations

on the second fitting and install the

bypass between the two machines.

Equalize the pressure (

P.

) of the first

slide gate valve. For this operation

rotate the knob that controls

equalizing valve counter-clockwise

until it stops.

39. Open the slide gate valve.

40. Open the machine bypass.

41. Open the machine bypass

located on the second stopping

machine.

!

!

O.

Long Handle

Short

Handle

N.

Cleaning /

Inspection

Machine

with

Viewer

Brush

!

Q.

Long Handle

Short

Handle