MUELLER

®

Shur Stop

TM

Unit 812 PE Line Stopping System

Operating Instructions

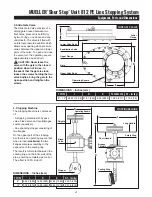

11

48. If leakage occurs between the

stopper bar and the sealing disk

gradually tighten the Allen screws.

49. Repeat the same operations on

the second stopper machine.

50. Purge remaining gas through No.

1 and No. 2 (

r.

).

51. Tighten the safety ring.

52. Make the repairs.

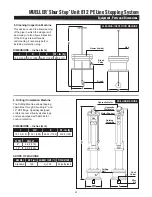

53. Before decompressing the

sealing ring, it is necessary to

equalize the pressure upstream and

downstream of the same stopper (

s.

).

When only gas comes out of the vent

No. 2, close the respective gate valve

letting the gas equalize pressure.

It is now possible to test the new

connections (

T.

).

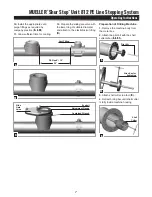

54. Decompress the sealing ring of

the stopper by operating counter-

clockwise on the ratchet handle until

a hard stop and retract the stopper

inside the stopping machine.

55. Repeat the same operations on

the second stopping machine (

U.

).

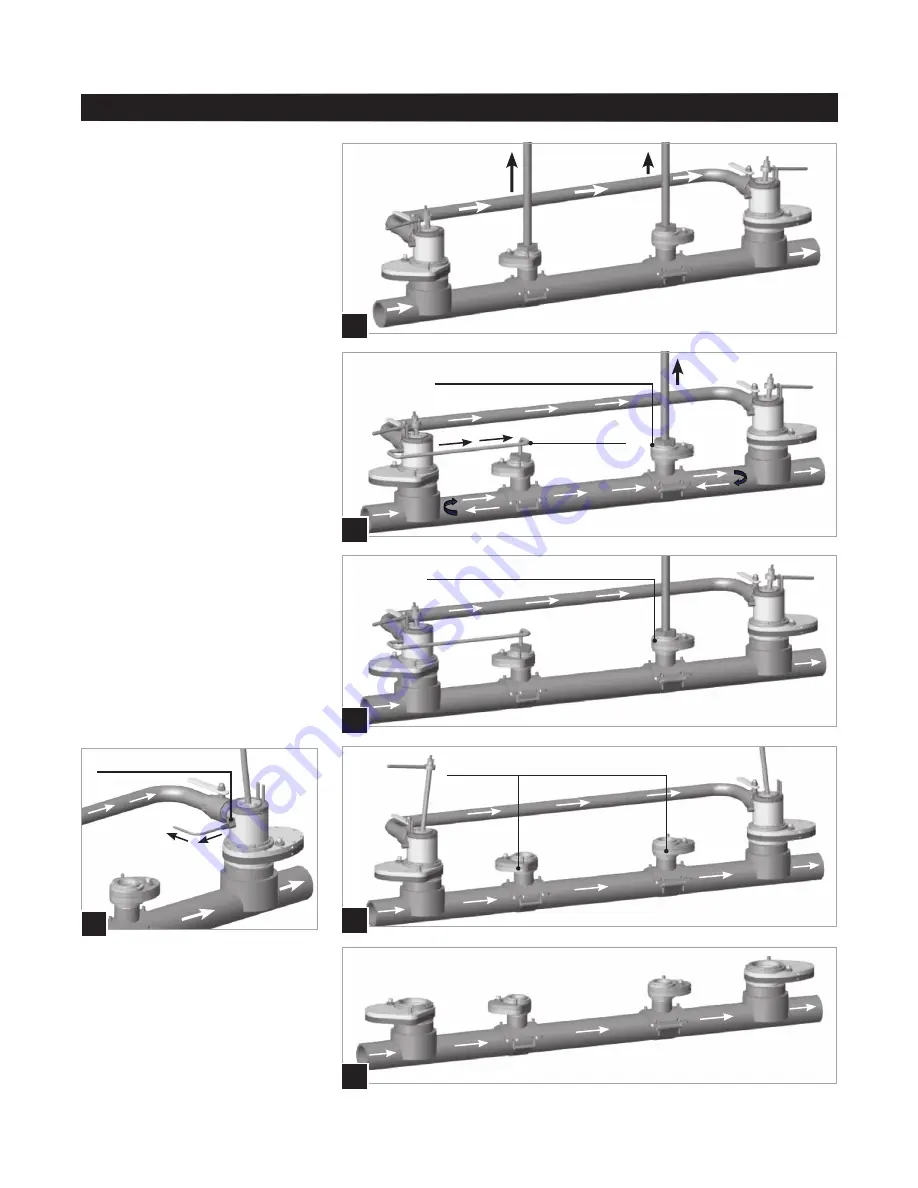

56. Close the related slide gate

valves.

57. Bleed the gas contained in the

bypass at a suitable distance from

possible sources of ignition (

v.

).

58. Remove the bypass and the

stopping machines (

w.

).

r.

No. 1

No. 2

v.

Bleed Valve

U.

Vent Closed

No. 1

No. 2

T.

Vent Closed

No. 1

No. 2

s.

No. 1

No. 2

Hose

Vent open for Purging

w.

No. 1

No. 2