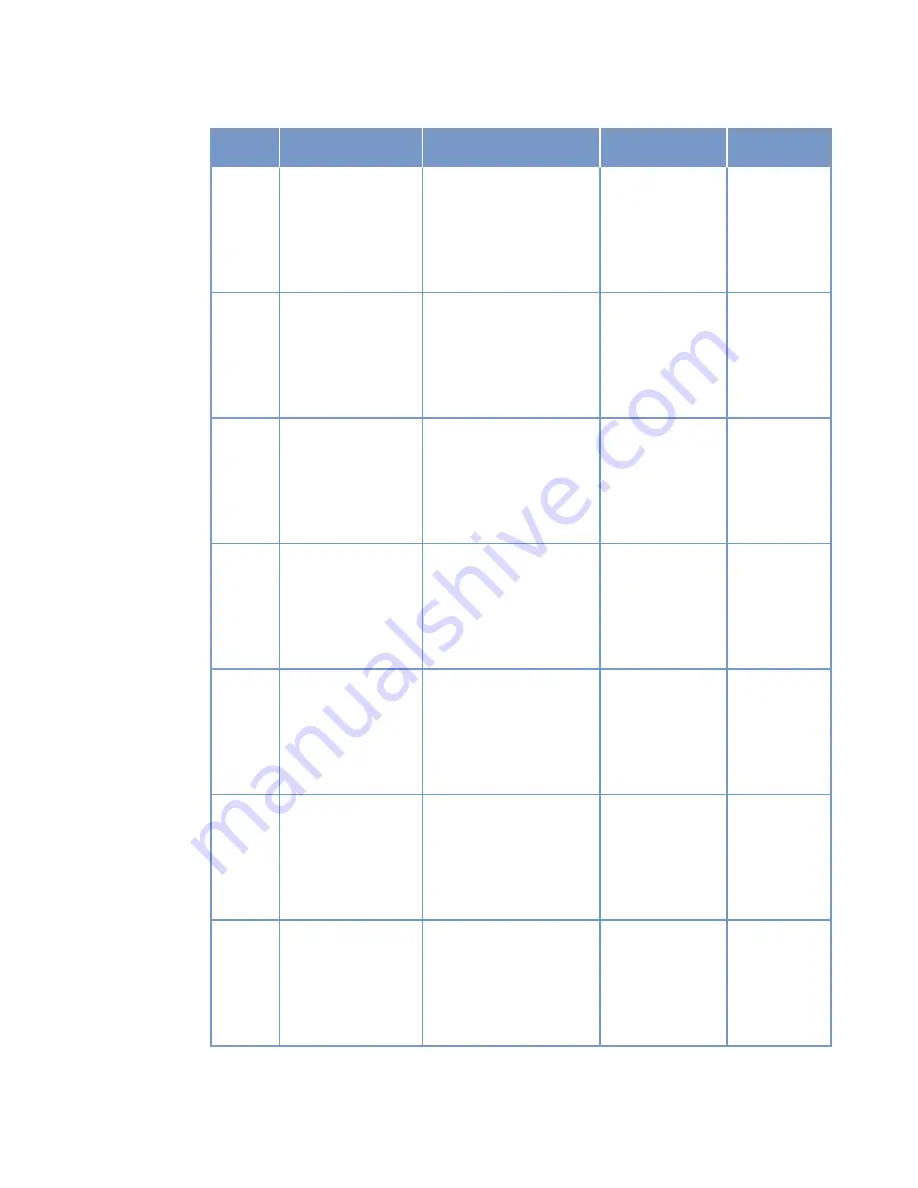

Fault

code no.

Full designation

Meaning

Action

Setting parame-

ter no.

308

AL Timing Cylinder A8

Time-of-flight measuring fault

injector cylinder A8 Time-of-

flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

1.8004.507

309

AL Timing Cylinder A9

Time-of-flight measuring fault

injector cylinder A9 Time-of-

flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

1.8004.508

310

AL Timing Cylinder A10 Time-of-flight measuring fault

injector cylinder A10: Time-

of-flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

1.8004.509

311

AL Timing Cylinder B1

Time-of-flight measuring fault

injector cylinder B1: Time-of-

flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

1.8004.510

312

AL Timing Cylinder B2

Time-of-flight measuring fault

injector cylinder B2: Time-of-

flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

1.8004.511

313

AL Timing Cylinder B3

Time-of-flight measuring fault

injector cylinder B3: Time-of-

flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

18004.512

314

AL Timing Cylinder B4

Time-of-flight measuring fault

injector cylinder B4: Time-of-

flight value measured ex-

tremely small or large (alarm

configuration parameter, see

PR 2.8008.100 for explana-

tion).

Replace plug-in

pump if this occurs

frequently.

1.8004.513

MS15018/02E 2013-09

| Troubleshooting | 51

TIM-ID: 0000008508 - 003