36

Rev. 1.0

0012072012

TSM24P User Manual

+86-400-820-9661

5.5.6 Verify the Drive Current

The amount of drive current can be verified at any time during the tuning process to make sure the

current supplied to the motor is not being limited by the drive. If too much current is being required

changes may be made to the move profile. Select

Current

in one of the

Plot

selection lists and

repeat the move, from this the current can be evaluated.

5.5.7 Finishing up

If the TSM will only be operated in a

Velocity Control Mode

with a

Speed only

Control Type, the

tuning is complete. The Position Loop

(P Loop)

does not need to be tuned as it is not used. After

verifying the drive current, the

Notch Filter

may be the only setting still needing adjusting. See

section 5.8 on “Setting the Notch Filter”.

If the TSM will be operated in a

Position Control Mode,

proceed to section 5.6 ”Tuning the

Position Loop” below.

See Section 5.7 below on “Using Auto Trigger Sampling” for tuning the TSM while using an

external Pulse & Direction controller.

5.6 Tuning the Position loop

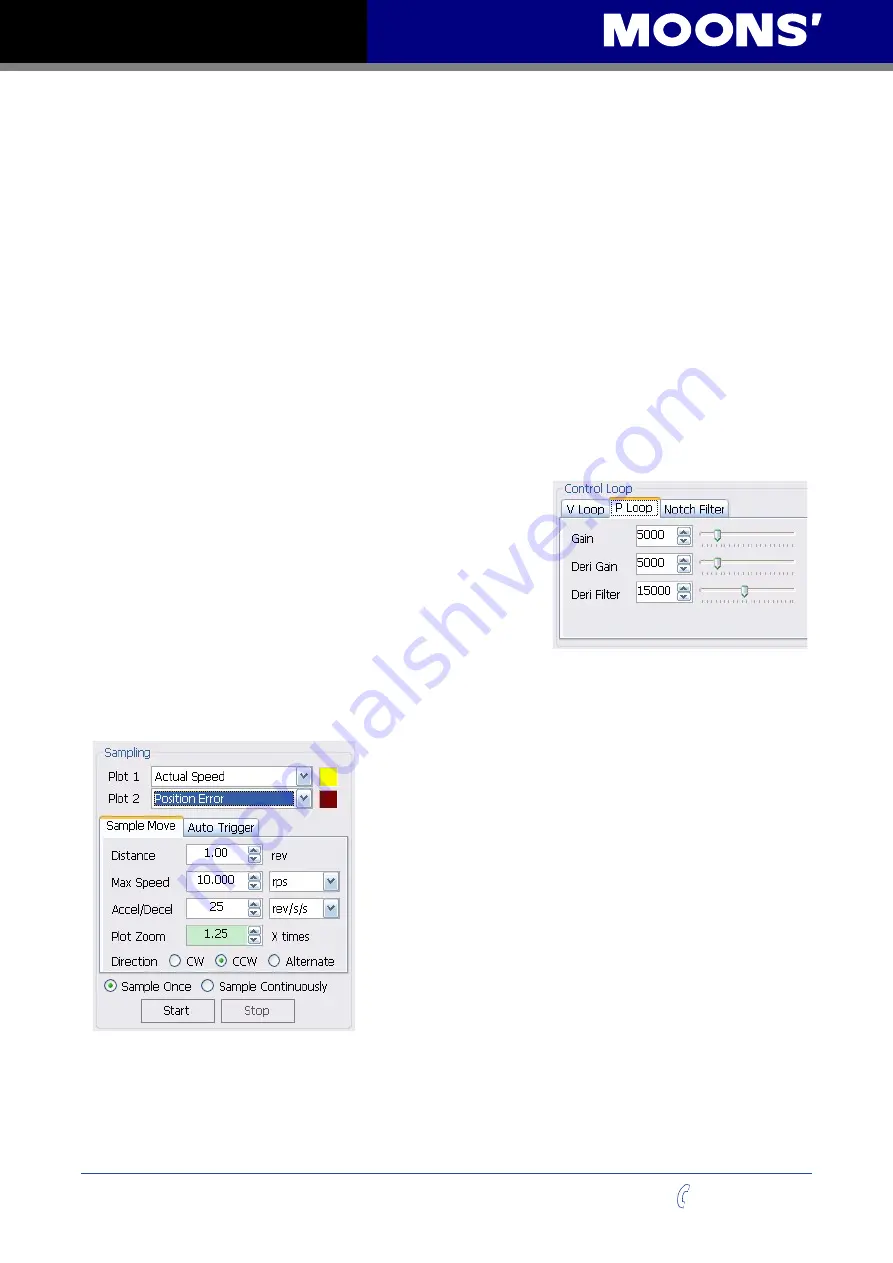

5.6.1 Entering a Sample Move

Select the

P Loop

tab in the

Control Loop

dialog section.

This will cause the

Sampling

to do moves that are based

on distance and operates the drive in the

Point to Point

Positioning mode.

Now the parameters for a

Position

based move can be

entered. There is one consideration that must be addressed

here. If the TSM is being operated in the

Position Control

Mode

with a

Pulse & Direction Digital Signal Type

setting

and being commanded by, for example, an external Pulse and Direction controller, the

Auto

Trigger

option may be used to capture and plot the move. See Section 5.6 on “Using the Auto

Trigger Sampling” for more details on this feature.

Plot 1 & Plot 2:

two different values can be selected for

viewing in the scope window, in this case

Actual

Speed

and

Position Error

are selected. For Position tuning these

are typical values.

Sample Move:

move profile values are entered in the

Sampling

section. This example sets a move

Distance

of

3.00 revs at a

Max Speed

of 20,000 rev/sec and an

Accel/

Decel

rate of 300 rev/s/s. In the window to the right of the

Sampling

data entry section the

Desired

Profile

will be

displayed. This provides a visual reference of what the

expected move will look like.

Plot Zoom:

the length of the plot values that are displayed

can be set from 1 to 5 times the profile length.

Dir:

the direction of the move can be set to

cw

,

ccw

or

alternate

. These directions refer to the motor shaft as viewed from the front of the motor.

Alternate

toggles the direction after each move. Start with a known direction before switching to

toggle.

Sample Once:

after the

Start

button is clicked, a single move is performed, the motor stops, and

the results will be displayed.