AS 914 TI

User Manual

49

2

10

4

a

c

d

e

b

and gradually offsets the abrupt uneven thickness

caused by the side ring.

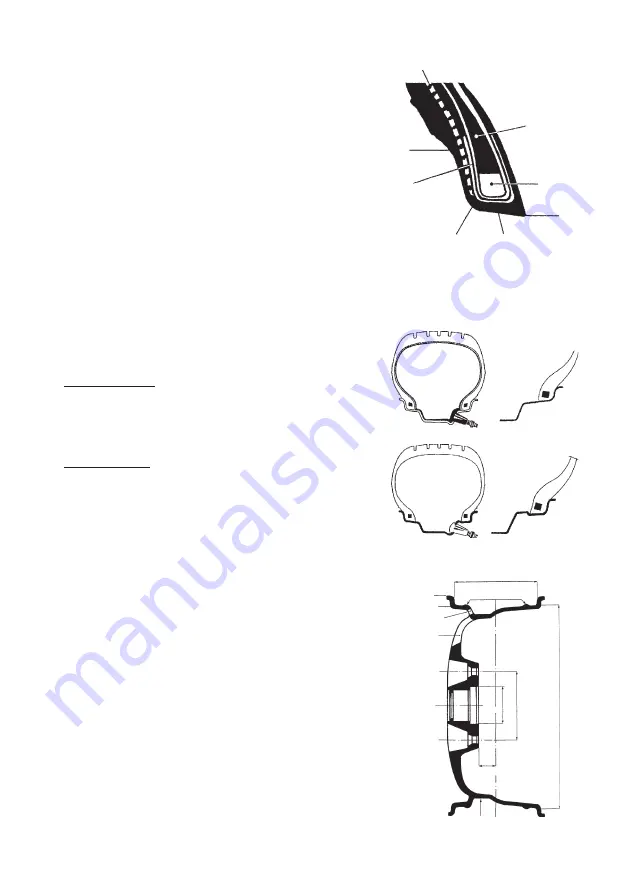

11 - Flap

. This is the part of the casing ply around the

side ring and placed against the casing, to secure the

ply and prevent it from slipping.

12 - Foot

. This is the innermost layer of the tread in

contact with the belt, or if the latter is not present

(conventional tyre) with the last casing ply.

13 - Shoulder.

This is the outer part of the tread, be-

tween the corner and start of the sidewall.

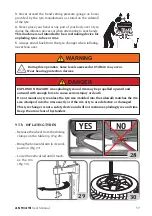

14 - Bead

. This is the part joining the tyre to the rim.

The bead point (a) is the inner corner. The spur (b)

is the outer part of the bead. The base (c) is the area

resting against the rim. The groove (d) is the concave

part against which the rim shoulder rests.

Tube type tyres. As a tyre has to contain pressurised

air for a fairly long time, an air chamber is used. The

valve for adding air and maintaining, controlling

and restoring air pressure is part of the chamber in

this case.

Tubeless tyres. Tubeless tyres consist of a tyre with

inner sidewall lined with a thin layer of special im-

permeable rubber, called

liner

. This liner helps to

maintain air pressure in the casing. This kind of tyre

must be mounted on a specific rim, to which the

valve is directly fixed.

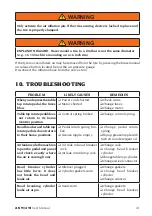

II - Rim (Wheel).

The wheel is the rigid metal part

which connects the vehicle hub to the tyre, on a fixed

but non-permanent basis.

Rim profile.

The rim profile is the form of the section in

contact with the tyre. It comprises different geomet-

ric forms, which ensure: easy tyre mounting (bead

insertion in the rim well); safe driving, in terms of

the bead anchored in its seat.

The rim section shows its various parts: a) rim width

– b) shoulder height – c) tubeless anchoring (HUMP)

– d) valve hole – e) ventilation opening – f) off set – g)

central hole diameter – h) attachment hole centre to

centre i) keying diameter – j) rim well.

III - Air chamber (tube type tyres).

The air chamber is

f

g h

i

a

c

b

d

e

j