FineAdjust Applicator

Doc. No: TM-638004900

Release Date: 09-04-03

UNCONTROLLED COPY

Page 15 of 50

Revision: G

Revision Date: 01-15-13

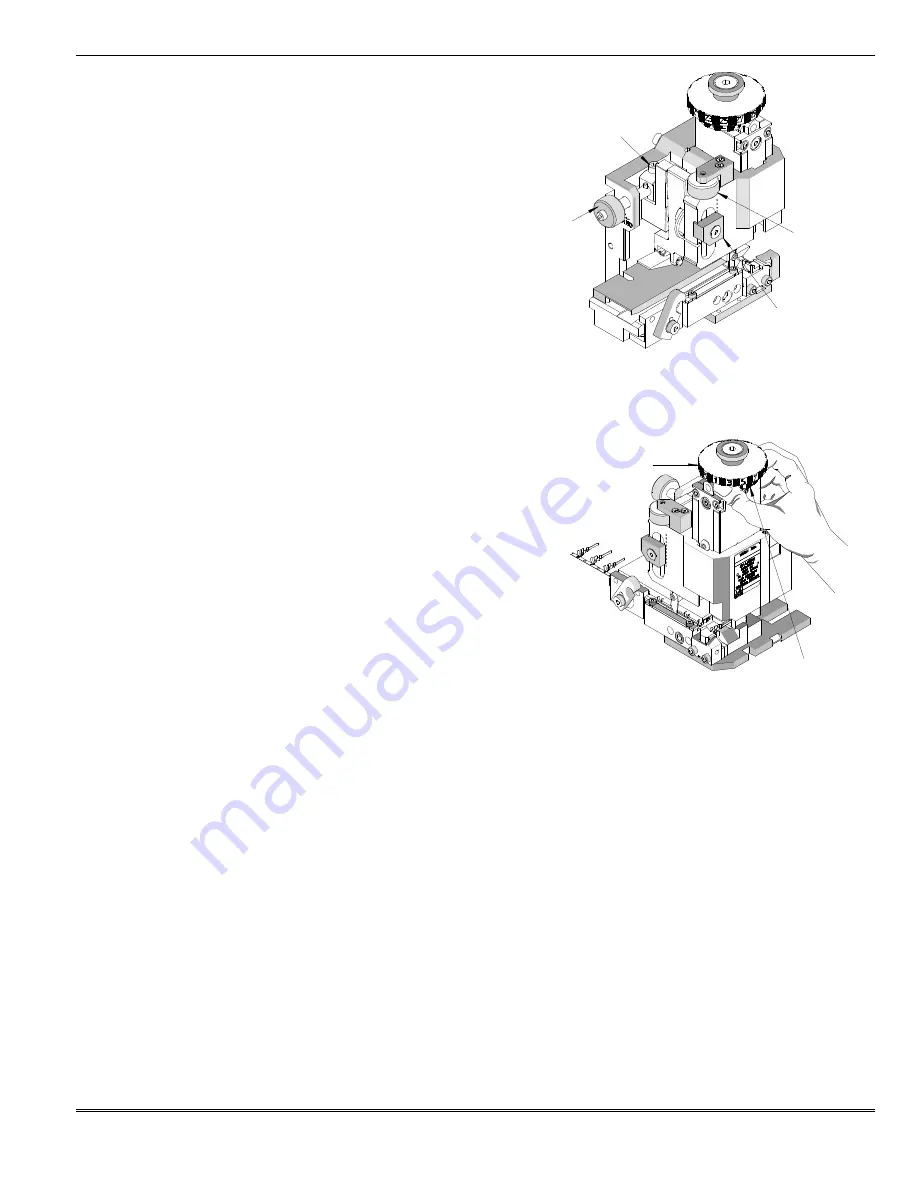

PIVOT CLAMP

M5 FHCS

FORWARD

FEED

STROKE

ADJ. KNOB

M5 SHCS

FEED LOCK

BACK

STROKE

ADJ. KNOB

Figure 2-10

Figure 2-11

INSULATION

CAM (TOP)

CONDUCTOR

CAM (BOTTOM)

Forward Feed Adjustments

1.

The forward feed position must locate the terminal that is

being crimped exactly over the anvils.

2.

Disconnect the power from the press. Remove the

machine guards if necessary.

3.

Make sure there is a terminal over the anvils and the feed

finger is fully forward (closest to the anvils).

4.

Loosen the M5 SHCS.

5.

Turn the forward feed adjusting knob to position the

terminal. To decrease the feed position, turn the forward

feed adjusting knob clockwise. To increase the feed

position turn the forward feed adjusting knob

counterclockwise. See Figure 2-10.

6.

When adjusting to decrease the feed position, it is

necessary to pull the terminal strip backwards until it is against the feed finger. When increasing the feed position, the feed

finger will push the terminal farther over the anvils.

7.

After properly adjusting the forward feed position of the terminal, tighten the M5 SHCS with a 4mm hex wrench.

Back Stroke Feed Adjustments

1.

To properly feed the terminal strip, the back feed stroke should have

enough over-travel to pick up the next terminal. Too much over

travel may, in some cases, cause a double-feed.

2.

Disconnect the power from the press. Remove the machine guards if

necessary.

3.

To achieve the correct backstroke location, adjust the position of the

hinge bushing. First, use a 3mm hex wrench to loosen the M5 FHCS

holding the pivot clamp. Turning the backstroke adjustment knob

(which is located above the hinge bushing) clockwise will raise the

hinge bushing and will increase the backstroke. Turning the knob

counter clockwise (CCW) will lower the hinge bushing and will

decrease the feed backstroke. When adjustment is complete, tighten

the pivot clamp securely. See Figure 2-10.

4.

Since back feed stroke adjustment may not be visibly obvious, the terminal feed should be cycled (by hand, if possible) to

observe the changes.

5.

Back feed stroke adjustments may affect the entire feed linkage; re-adjustment of the forward feed stroke could be

necessary. See Forward Feed Adjustments.

Conductor Crimp Punch Adjustments

1.

With the guards intact, place a stripped length of suitable wire into the terminal and terminate the wire under power.

2.

Inspect the quality of conductor crimp and measure the crimp height. See Appendix A.3 Conductor Crimp Height

Measurement.

3.

If adjustments are necessary, turn off and disconnect the power supply from the press. Remove the machine guards.

4.

The desired crimp height can be achieved by rotating the conductor-adjusting cam. See Figure 2-11. Each increment

represents approximately 0.015mm (.0006") for a total adjustment of 1.80mm (.071"). The "A" setting is the loosest crimp

height and the "N" setting is the tightest. If you find that the crimp height is not acceptable, you can rotate the adjusting cam

until the desired crimp height is obtained. See Section 2.1, Shut Height. No shimming of the applicator is required.

5.

Replace the machine guards and repeat the previous steps until the desired crimp height is obtained. See Appendix A.3,

Conductor Crimp Height Measurement.

6.

Perform a pull test on conductor crimp to verify the mechanical integrity of the crimp. See Appendix A.5, Pull Force Test.