Hand Crimp Tool for Ditto Wing Genderless Interconnects Terminals

Doc No: ATS-638278600

Release Date: 09-29-15

UNCONTROLLED COPY

Page 3 of 8

Revision: B

Revision Date: 08-20-19

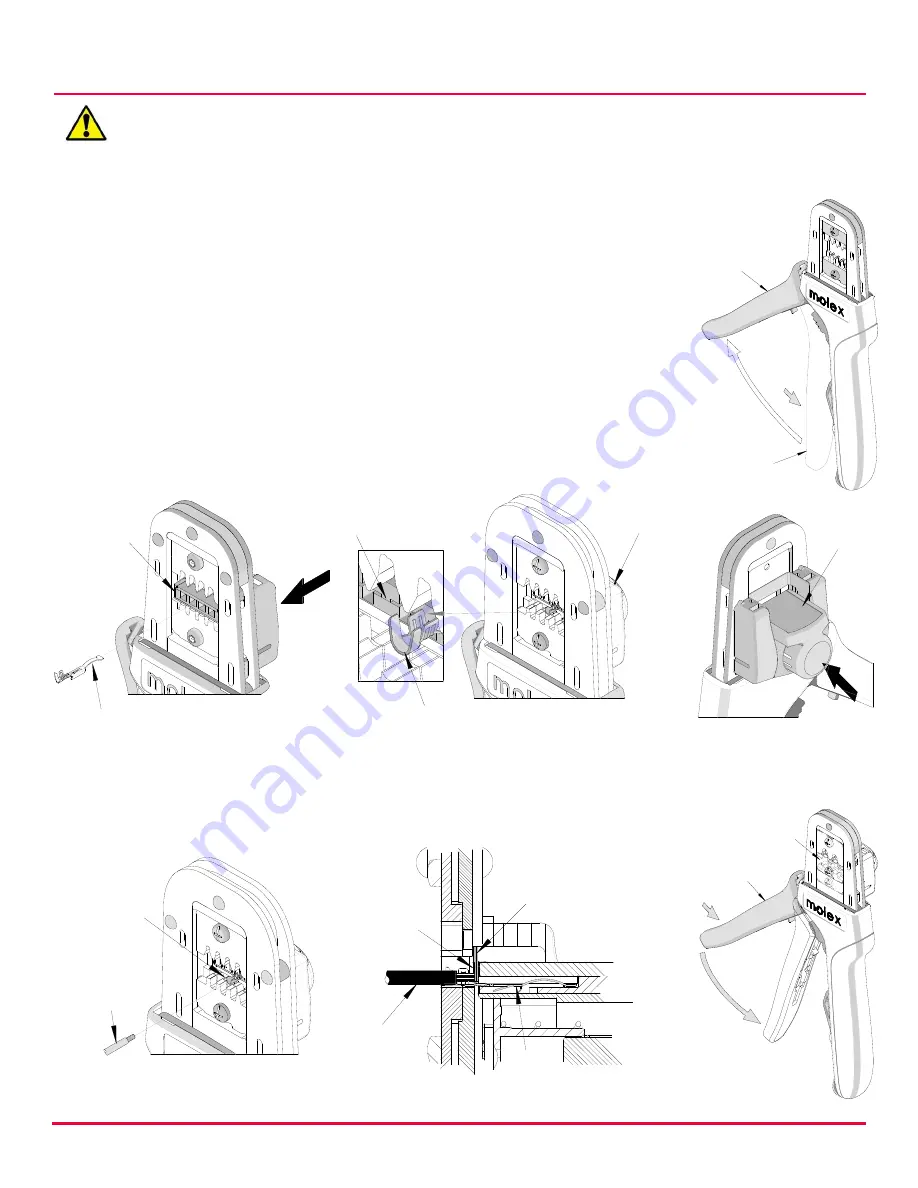

Figure 5

TERMINAL

WIRE AGAINST

THE WIRE STOP

WIRE

WIRE STOP IS PART

OF THE LOCATOR

PRE-STRIPPED

WIRE

TERMINAL

RELEASE

LOCATOR BUTTON

TERMINAL

Figure 3

LOCATOR

PUSHED

THROUGH

TOOLING

TERMINAL

LOCATOR

BUTTON

PUSHED IN

LOCATOR

OPERATION

CAUTION:

Crimp only the Molex terminals listed in the scope for this tool. Do not crimp

hardened objects as damage can occur to the tool frame or crimp dies.

Open the tool by squeezing the handles together. At the end of the closing stroke, the ratchet

mechanism will release the handles and the hand tool will spring open. See Figure 1.

Crimping Terminals

1.

Select the desired terminal listed from the preceding charts and

install it in the proper locator (See chart above and see Locator

Replacement on page 4).

2.

Make sure the center of the locator is in the down position. With the

locator attached, push the locator button on the back of the hand

tool to bring the locator forward through the tooling. See Figure 2.

3.

While holding in the locator button, load the terminal into the proper

nest opening in the locator, based on the wire gauge or terminal

type markings on the hand tooling. See Figure 3.

4.

Release the locator button, allowing the locator to return to the

crimping position.

5.

Close the tool handle until the first ratchet position engages. See Figure 4.

6.

Insert the properly stripped wire through the terminal and

against the wire stop. See Figure 5.

PARTIALLY

CLOSE HANDLE

TOOLING

PARTIALLY

CLOSED

Figure 4

FIRST RATCHET

POSITION

OPEN

POSITION

SQUEEZE

HANDLES

TOGETHER

HANDLE WILL

SPRING OPEN

Figure 1

LOCATOR

IN DOWN

POSTION

PUSH ON THE

LOCATOR BUTTON

Figure 2