Hand Crimp Tool for Ditto Wing Genderless Interconnects Terminals

Doc No: ATS-638278600

Release Date: 09-29-15

UNCONTROLLED COPY

Page 2 of 8

Revision: B

Revision Date: 08-20-19

▲

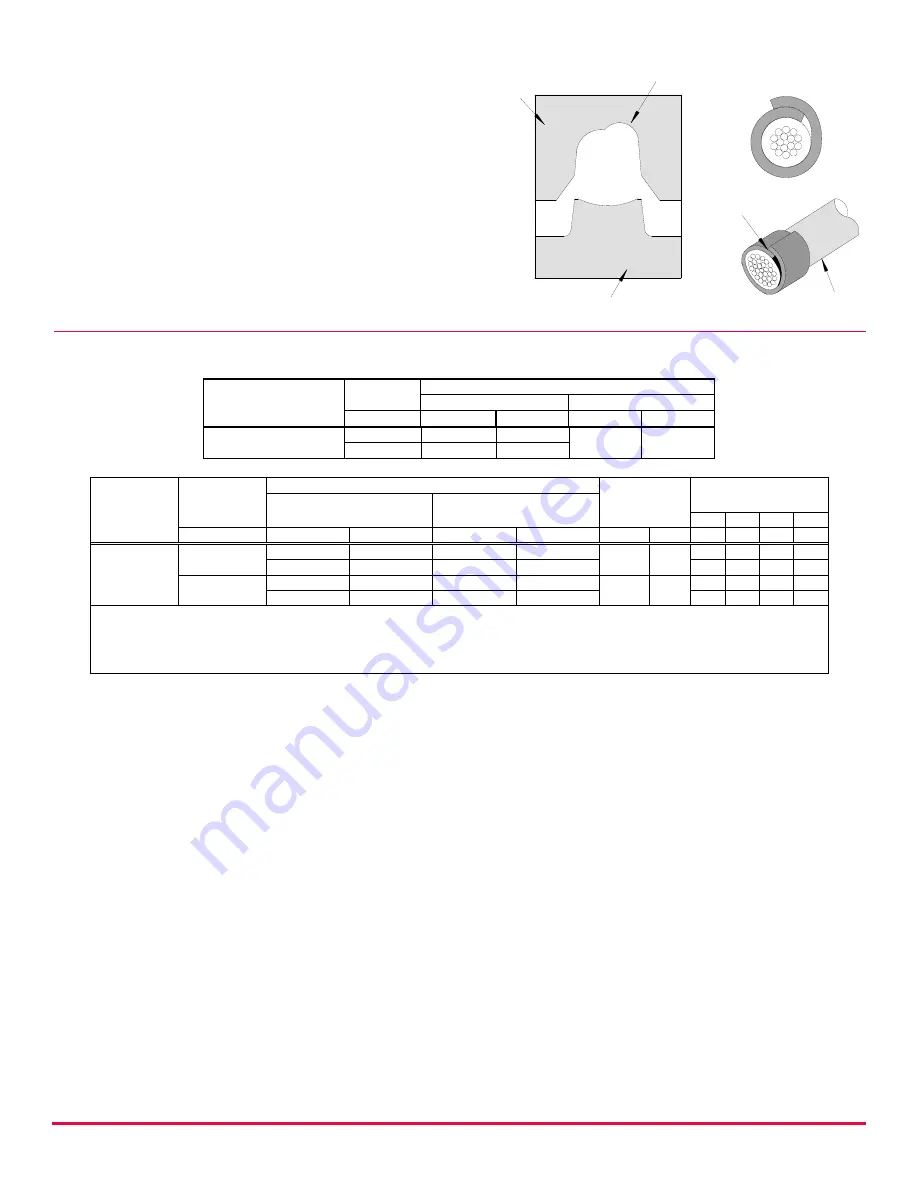

Insulation Crimp Note

Due to the terminal’s insulation grip design

and insulation diameter range, this tool uses

overlap form geometry in the insulation

punch. This produces an overlap insulation

crimp (A-620 compliant). Although the

insulation punch profile may appear lopsided,

this is a normal condition for this tool. See

figure to the right. Some tools with multiple

crimp pockets may not have the overlap

profile on all pockets.

CONDITIONS

After crimping, the conductor profiles should measure the following:

Terminal Series No

Wire Size

Conductor Crimp

Height

Width

AWG

mm

In.

mm

In.

150197

150200

24

0.95–1.05 .037-.041

1.40-1.50 .055-.059

26

0.95–1.00 .037-.039

Terminal

Series No

Wire Size

Insulation Crimp Maximum

Pull Force

Minimum

Profile

Height (Ref.)

Width (Ref.)

A

B

C

D

AWG

mm

In.

mm

In.

N

Lb.

26 24 24 26

150197

150200

24

1.75-1.85

.069-.073

1.75-1.85

.069-.073

26.7

6.0

X

1.55-1.65

.061-.065

1.55-1.65

.061-.065

X

26

1.75-1.85

.069-.073

1.75-1.85

.069-.073

17.8

4.0

X

1.50-1.60

.059-.063

1.40-1.50

.055-.059

X

▲

To achieve IPC/WHMA-A-620 Class 2 crimps, the following overall wire insulation diameter ranges are recommended:

Profile A:

1.30-1.40mm (.051-.055”)

Profile C:

1.10-1.20mm (.043-.047”)

Profile B:

1.35-1.55mm (.053-.061”)

Profile D:

0.80-1.00mm (.031-.039”)

Tool Qualification Notes

1. Pull force should be measured with no influence from the insulation crimp.

2. The above specifications are guidelines to an optimum crimp.

Note

A crimp height chart is provided with this document as Reference Only. Due to the wide range of

wires, strands, insulation diameters, and durometers available, actual crimp height measurements

may very slightly. An occasional destructive pull force test should be performed to check hand tool

crimp. Pull force value must exceed the minimum pull force specifications listed.

OVERLAP

INSULATION

CRIMP

OVERLAP FORM GEOMETRY

ANVIL

PUNCH

WIRE