01/08 AWB2190-1430GB

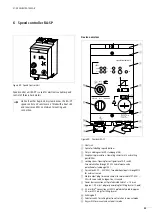

Setting the functions with DIP

switches/jumpers

81

Activate phase reversal switch (pole 7)

Table 14: Phase reversal and reversing function

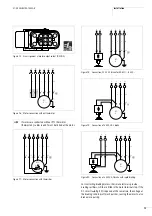

Configure external outputs (pole 5 – 6, 8)

The RA-MO provides two external inputs for connecting light

barriers, sensors, etc. Add-on functions are:

• Quick stop with a light barrier for both directions

• Quick stop and interlocked manual mode with both light

barriers for clockwise rotation

• Quick stop with one light barrier per operating direction

• Interlocked manual operation with one light barrier per

operating direction

• When using break contacts, inversion of the signals for internal

processing.

You can configure the external inputs through pins 5, 6 and 8 of

the DIP switch:

Table 15: Sensors

Table 16:

Setting quick stop and interlocked manual mode

Monitoring the lower current limit with RA-MO24V

Table 17: Monitoring the lower current limit

Diagnostic status through AS-Interface

®

parameter

channel

Table 18: Diagnostic status through AS-Interface

®

parameter channel

h

For this setting, the jumper on the right must be in its left

position (

a

fig. 85).

j

Danger!

Safety risk! The jumper positions and the setting of DIP

switch pole 7 must be changed only by trained persons

and only in accordance with this manual. Incorrect

settings will reverse the operating direction.

pole 7

Configuration

0

Reversing starter (factory setting)

1

Reversing starters and phases L1 and L3 reversed (phase

reversal)

pole 5

Configuration

0

Sensor signals through AS-Interface®, no add-on function

(factory setting)

1

When using sensors with break contacts:

Signals are inverted for internal processing; the original

signals are sent through AS-Interface®.

Pole

Configuration for RA-MO…

6

8

0

0

No add-on function (factory setting)

1

0

With jumper setting Reversing starter:

Quick stop, I3 enabled. I3 is assigned to both operating

directions, I4 has no add-on function; typical application

example: chain discharger

With jumper setting DOL starter:

Quick stop and interlocked manual operation (edge-

controlled only), I3 and I4 enabled. I3 and I4 are assigned to

operating direction FWD; typical application: vertical sorter

with > 360° eccentric

0

1

Quick stop, I3 and I4 enabled.

I3 is assigned to operating direction FWD,

I4 is assigned to operating direction REV;

Typical application: Vertical sorter with

< 360° eccentric

1

1

Quick stop and interlocked manual operation, I3 and I4

enabled. I3 is assigned to operating direction Forward, I4 to

operating direction Reverse; typical example: Vertical sorter

with < 360 ° eccentric

h

With RA-MOL… manual operation is not possible.

pole 9

Configuration

0

Monitoring of lower current limit disabled

(factory setting)

1

Monitoring of lower current limit enabled

h

In 400 V models current monitoring is always enabled.

pole 10

Configuration

0

Diagnostic status through AS-Interface

®

parameter channel

and I/O error signal disabled (factory setting).

1

Diagnostic status through AS-Interface

®

parameter channel

and I/O error message enabled.

Содержание Rapid Link

Страница 10: ...01 08 AWB2190 1430GB 6 ...

Страница 40: ...01 08 AWB2190 1430GB 36 ...

Страница 48: ...01 08 AWB2190 1430GB 44 ...

Страница 70: ...01 08 AWB2190 1430GB 66 ...

Страница 145: ...01 08 AWB2190 1430GB Parameterization with DrivesSoft 141 Figure 134 Example acceleration time ...

Страница 146: ...01 08 AWB2190 1430GB 142 ...

Страница 162: ...01 08 AWB2190 1430GB 158 ...