FUEL SYSTEM <DOHC>

13-295

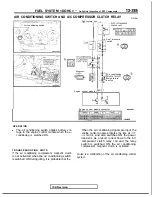

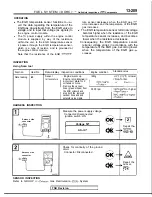

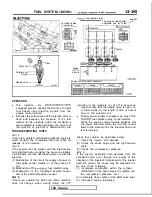

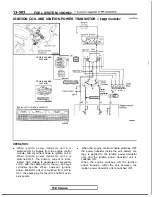

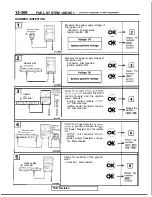

Filter

Connector

Solenoid coil

Plunger

Needle valve

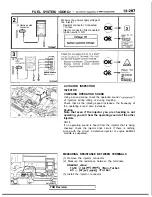

fuel injection relay

I

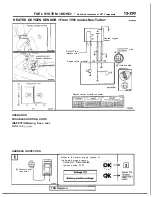

The area enclosed with

is

Harness side

applicable onlv for Turbo.

connector

Engine

module

Engine control module connector

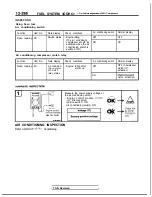

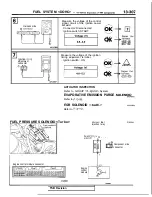

OPERATION

l

The

injectors

are

equipped injection nozzles that function to inject

fuel based upon injection signals from the

engine control module.

l

Because the surface area of the injection ports is

fixed and because the pressure of the fuel

relative to the pressure within the manifold is

also regulated to a fixed pressure, the amount of

fuel injection by injectors is determined by the

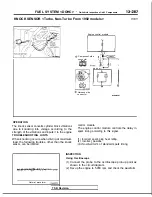

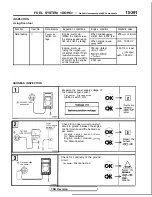

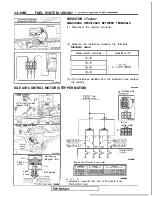

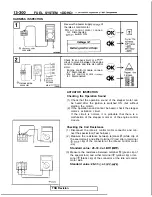

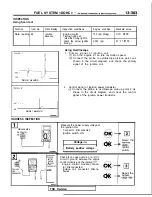

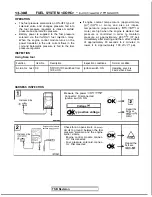

TROUBLESHOOTING HINTS

Hint 1:

If there is a problem with starting while the engine is

warm, perform the combustion test and check for

leakage of the injectors.

Hint 2:

If the engine can’t be started, and the injectors are

not activated during cranking, the cause is probably

a malfunction such as described below, not with the

injectors.

(1) Malfunction of the circuit for supply of power to

the engine control module, or of the ground cir-

cuit.

(2) Malfunction of the

fuel injection relay.

(3) Malfunction of the crankshaft position sensor

and/or the camshaft position sensor.

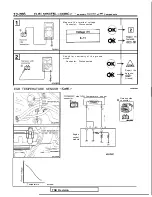

Hint 3:

If there

is

a cylinder for which the idling condition

does not change when, during idling, the

injection of the injectors is cut off in sequence,

length of time that the needle valve is open, or,

in other words, by the length of time of current

flow to the solenoid coil.

l

Battery power supply is supplied, by way of the

fuel injection relay, to the injectors.

When the engine control module switches ON

the power transistor within the unit and current

flows to the solenoid coil, the injectors open and

fuel is injected.

check that cylinder as described below.

Check the injector and harness.

(2) Check the spark plugs and the high-tension

cable.

(3) Check the compression pressure.

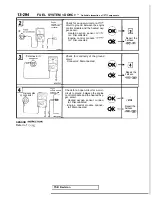

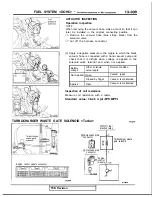

Hint 4:

if the injector activation time deviates from the

standard value even though the results of the

checking of the injector’s harness and of the injector

itself are normal, the cause may be pressumed to

be one of the following,

(1) Incomplete combustion within the cylinder.

(Malfunction of the spark plugs, the ignition coil,

the compression pressure, etc.)

(2) Incomplete close contact of the EGR valve seat.

(3) Increased engine resistance.

TSB Revision

Содержание 1989 Galant

Страница 2: ......

Страница 4: ...00 z NOTES ...

Страница 274: ...13 132 NOTE ...

Страница 282: ...13 140 On Vehicle Inspection of MFI FUEL SYSTEM SOHC 16 VALVE Components 6FU 0985 6FUO99 J TSB Revision ...

Страница 512: ...AUTO CRUISE CONTROL SYSTEM Troubleshooting Accelerator pedal switch 07R003E 1750407 TSB Revision ...

Страница 586: ...NOTES ...

Страница 650: ...NOTE ...

Страница 664: ...NOTES ...

Страница 688: ...NOTES ...

Страница 690: ......

Страница 692: ......

Страница 694: ......

Страница 696: ......

Страница 698: ......

Страница 700: ...c ...

Страница 702: ......

Страница 704: ......

Страница 706: ......

Страница 708: ......

Страница 710: ......

Страница 712: ......

Страница 714: ......

Страница 716: ......

Страница 718: ......

Страница 720: ......

Страница 722: ......

Страница 724: ......

Страница 729: ...23 23 NOTES ...

Страница 860: ...NOTES ...

Страница 921: ...NOTES ...

Страница 948: ...33B 9 NOTES ...

Страница 1016: ...ACTIVE ELECTRONIC CONTROL SUSPENSION Troubleshooting 33B 77 A 58 A 63 __ 111111111 Ground point detailed view TSB Revision ...

Страница 1021: ...33B 82 ACTIVE ELECTRONIC CONTROL SUSPENSION Troubleshooting INTERIOR 16AO353 crossmembe WA0492 1 TSB Revision I ...

Страница 1121: ...NOTES ...

Страница 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Страница 1273: ...NOTES t ...