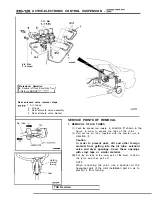

ACTIVE-ELECTRONIC CONTROL SUSPENSION

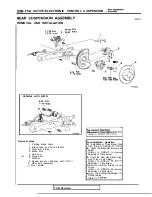

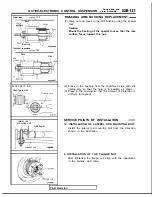

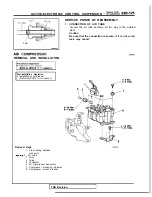

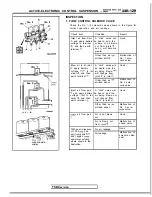

Air compressor

075

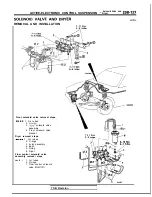

Exhaust solenoid valve

SERVICE POINTS OF REMOVAL

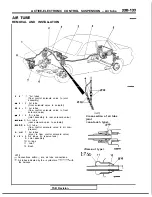

2. REMOVAL OF AIR TUBE

Caution

1. In order to prevent dust, dirt and other foreign

material from getting into the air tube and air

compressor openings, cover these opening with

vinyl tape or similar material.

2. Be careful not to bend the air tubes.

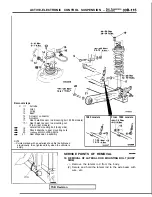

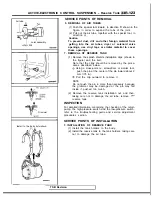

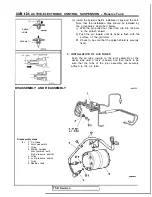

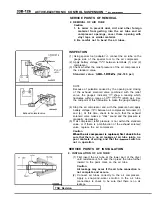

INSPECTION

(1) Using special tool (adaptor

connect the air tube on the

gauge side of the special tool to the air compressor.

(2) Apply battery voltage

between terminals (1) and (2)

compressor.

(3) Check whether the relief pressure of the air compressor is

the standard value.

Standard value:

(142-185 psi)

NOTE

Because of pulsation caused by the opening and closing

of the exhaust solenoid valve combined with the relief

valve, the gauge’s indicator

show a reading which

fluctuates within a range of

(29-43 psi). Use

the mid-point of this fluctuation to make the gauge reading.

(4) Stop the air compressor and, with the pressure held, apply

battery voltage

between air compressor terminals (3)

and (4). At this time, check to be sure that the exhaust

solenoid valve makes a “click” sound and the pressure is

gradually decreasing.

(5) If air compressor relief pressure is not within the standard

value, or if there is a malfunction of the exhaust solenoid

valve, replace the air compressor.

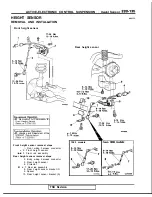

Caution

When the air compressor is replaced, first check to be

sure that there is no air leakage at air tube joints, no

poor contacts of wiring, and that the

switch is

not in operation.

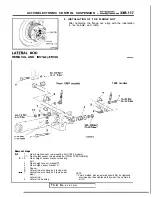

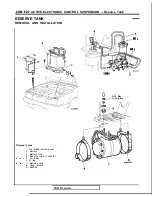

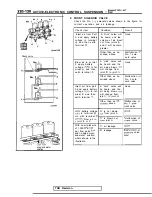

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF AIR TUBE

(1) First insert the air tube at the lower part of the dryer

until resistance is felt, and then press the tube further

inward to the paint mark on the air tube.

Caution

Air leakage may occur if the air tube connection is

not complete and secure.

(2) Connect air tubes correctly to the air compressor.

Apply a soap-and-water solution to the air tube

connections to check to be sure that there is no air

leakage.

TSB Revision

Содержание 1989 Galant

Страница 2: ......

Страница 4: ...00 z NOTES ...

Страница 274: ...13 132 NOTE ...

Страница 282: ...13 140 On Vehicle Inspection of MFI FUEL SYSTEM SOHC 16 VALVE Components 6FU 0985 6FUO99 J TSB Revision ...

Страница 512: ...AUTO CRUISE CONTROL SYSTEM Troubleshooting Accelerator pedal switch 07R003E 1750407 TSB Revision ...

Страница 586: ...NOTES ...

Страница 650: ...NOTE ...

Страница 664: ...NOTES ...

Страница 688: ...NOTES ...

Страница 690: ......

Страница 692: ......

Страница 694: ......

Страница 696: ......

Страница 698: ......

Страница 700: ...c ...

Страница 702: ......

Страница 704: ......

Страница 706: ......

Страница 708: ......

Страница 710: ......

Страница 712: ......

Страница 714: ......

Страница 716: ......

Страница 718: ......

Страница 720: ......

Страница 722: ......

Страница 724: ......

Страница 729: ...23 23 NOTES ...

Страница 860: ...NOTES ...

Страница 921: ...NOTES ...

Страница 948: ...33B 9 NOTES ...

Страница 1016: ...ACTIVE ELECTRONIC CONTROL SUSPENSION Troubleshooting 33B 77 A 58 A 63 __ 111111111 Ground point detailed view TSB Revision ...

Страница 1021: ...33B 82 ACTIVE ELECTRONIC CONTROL SUSPENSION Troubleshooting INTERIOR 16AO353 crossmembe WA0492 1 TSB Revision I ...

Страница 1121: ...NOTES ...

Страница 1200: ...SERVICE BRAKES Brake Pedal 35 79 Lubrication points Part A 14AO256 1 14UOO5l TSB Revision ...

Страница 1273: ...NOTES t ...