Microsemi Proprietary and Confidential. LX3301A/LX3302A Auto Calibration User Guide Revision 1.0

14

4.2

Example Data and EEPROM Parameters Loaded

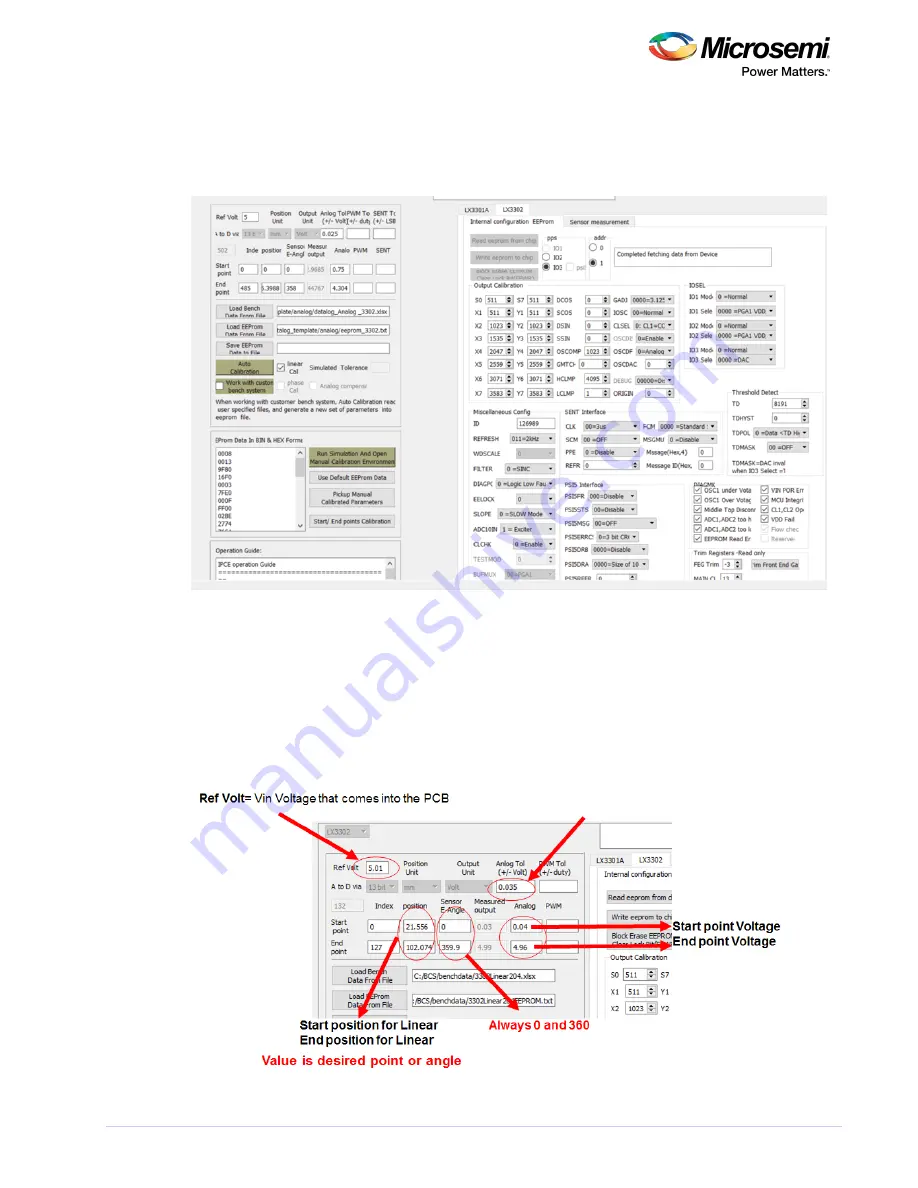

The following image shows an example of loaded data and EEPROM parameters.

Figure 23 • Example Loaded Data and EEProm Para Loaded

4.3

Calibration Condition Settings

The following image shows the calibration condition settings. The example given is 35 mV. This means

that any given position on the output could be accurate within 35 mV.

IF ANALOG (DAC) output is used, measure VIN from the sensor board connector.

Analog Tol= the Autocal system will calibrate up to this accuracy.

Figure 24 • Calibration Condition Setting