8

7

STRUCTURE – MAIN MENU

Boiler settings

Preset boiler temperature

Weather control the boiler*

Boiler heating curve*

Curve shift*

Room temperature factor*

Output modulation

Max. boiler output

100% fan speed

100% Oxygen*

50% fan speed

50% H2 hysteresis

Medium boiler output

50% fan speed

30% H1 hysteresis

Min. boiler output

30% fan speed

30% Oxygen*

Boiler hysteresis

Feeder correction

FL min. boiler output

FL max. boiler output

Ignition fan speed

– grate*

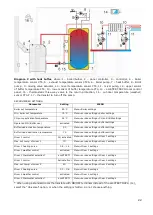

Heat source

Burner

Grate

Auxiliary boiler*

Regulation mode:

Standard

FuzzyLogic

Max kW

Avg kW

Min kW

Fuel Selection

Fuel level

Alarm level

Fuel level calibration

Lambda calibration*

Scheduled operation

On [No/Yes]

Schedule

Night time decrease boiler

On [No/Yes]

Reduction value

Schedule

HUW settings

HUW preset temperature

HUW pump mode

Off

Priority

No priority

HUW container hysteresis

HUW disinfection

Night time decrease HUW

On [No/Yes]

Reduction value

Schedule

Night time decrease circulation pump*

On [No/Yes]

Schedule

Mixer 1-4 settings*

Preset mixer temperature

Mixer room thermostat

Mixer weather control*

Heating curve mixer*

Curve translation*

Room temperature *

Mixer night time decrease

On [No/Yes]

Reduction value

Schedule

General settings

Clock

Date

Screen brightness

Sound

Language

Software update*

WiFi settings*

*

unavailable if no adequate sensor or

additional module is connected or the

parameter is hidden.

Main menu

Information

Boiler settings

HUW settings*

Summer mode

[Winter/Summer]

Mixer 1-4 settings*

General setting

Manual control

Alarms

Regulator On/Off

Service settings

Содержание ecoMAX860P2-T

Страница 2: ...2...

Страница 6: ......

Страница 7: ...REGULATOR INSTRUCTION MANUAL ecoMAX860P2 T...

Страница 19: ...19 CONTROLLER INSTALLATION AND SERVICE SETTINGS MANUAL ecoMAX860P2 T...

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ......

Страница 47: ......

Страница 48: ...Jacek Kucharewicz ul Sikorskiego 66 16 100 Sok ka Poland tel 48 85 711 94 54 www metalfachtg com pl...