Page 22 / IM 685

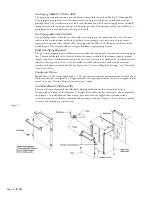

5. Reinstall the inspection door

➂

. Snug the screws but do not overtighten and crush the insulation.

6. Reinstall a turbulator in each tube approximately flush with the tube ends. The end of the

turbulators are formed such that the end will bind within the tube end and lock the turbulator in

place.

7. Reinstall flue box front wrap

➀

.

Figure 13. Models 032 thru 200 Heat Exchanger

Models 020 thru 025 (see Figure 14)

1. To gain access to the inside of the combustion chamber, detach the burner from the furnace and set

it on the floor of the vestibule (see Figure 14, Item

➂

). The burner is attached to the furnace studs

with four nuts. Conduit lengths allows this movement of the burner without disconnecting wiring.

The union on the gas line must be opened.

2. Remove the flue box front wrap

➀

.

3. Remove and clean the turbulator

➁

from each tube and clean the flue box.

4. Clean each tube with a 2

1

⁄

2

" round flue brush.

5. Remove the brushings and if required clean the combustion chamber and header through the burner

mounting tube.

6. Reinstall the burner.

7. Reinstall a turbulator in each tube approximately flush with the tube end, locking them in place with

the wedge clips on each turbulator.

8. Reinstall flue box front wrap

➀

.

Figure 14. Models 020 thru 025 Heat Exchanger

Leakage Symptoms

1.

Odor –

Odors in the building are usually being brought in through the outdoor air intakes and do

not indicate leakage from the furnace. Check for down draft conditions and check the location of the

flue exhausts of other equipment that may be pulled into the outdoor air intake. A major and

obvious furnace rupture can be a source of odor. In general, small leaks in a furnace will not be a

source of odor or danger because the pressure created by the supply fan is greater than the pressure

inside the furnace. Therefore when the supply fan is operating, leakage will be

into

the furnace, not

out of

the furnace and into the air stream. If the control system is such that the furnace comes on

and warms up the heat exchanger before the supply air fan comes on, and there is odor when the

supply fan first comes on, this could be caused by leakage. During the time the furnace is on and the

supply fan is off the leakage would be out off the furnace and then when the supply fan came on it

would blow those products of combustion into the supply duct.