IM 685 / Page 13

The air control valve will be at the minimum position during off cycles. Upon a call for heat or any

other time that a prepurge cycle occurs, the air control valve will be repositioned to the maximum

position for the prepurge and then returned to the minimum position for low fire start.

Through the N/C contacts for (R20) and (R23), the burner air and gas control valves are positioned to

minimum after a run cycle. When (R20) is energized for a new call for heat, (VM1) through the N/O

contacts of (R20) and the N/C contacts of (R21), will reposition the burner air valve to its maximum

open position for prepurge. When the air control valve reaches the full open position switch (LS2) is

'made', powering (FSG) terminal 7 through the burner air switch (AS). This initiates the 60 second

prepurge cycle. Concurrently, (LS2) powers timer (TD10) which will energize relay (R21) after 20

seconds. When (R21) is energized (VM1) will start the air control valve on its way toward the minimum

air valve position through the N/O contact of (R20) and (R21) and the N/C contact of (R23). At the

completion of the 60 second prepurge cycle the valve will be at the minimum open position and the

minimum position switch (LS1) will be "made". If (LS1) is not 'made', the start gas valves (GV1) will

not open and the burner will go out on safety lockout.

After completion of the 60 second prepurge period there will be a 10 second trial for ignition during

which terminal 8 (start gas valves - GV1) and terminal 10 (ignition transformer - IT) will be energized.

If flame is being detected through the flame rod (FD) at the completion of the 10 second trial for

ignition period, terminal 10 (ignition transformer - IT) will be de-energized and terminal 9 (relay coil -

R23 and main gas valves - GV4, etc.) will be energized and the control system will be allowed to control

the firing rate. The flame safeguard contains LEDs (lower left corner) that will glow to indicate

operation.

After the flame has lit and been proven, relay (R23) is energized allowing (VM1), as controlled by

(OBA4) and (OBA5), to position the burner air and gas valves for the required firing rate. When the

main control system closes (OBA5), the gas valve actuator will reposition toward a higher firing rate

until (OBA5) opens or the actuator reaches its maximum position. When the main control system

closes (OBA4), the actuator will reposition toward a lower firing rate. If neither (OBA4) or (OBA5) are

closed the actuator will remain at its present position.

In the event the flame fails to ignite or the flame safeguard fails to detect its flame within 10 seconds,

terminals 4, 8, 9 and 10 will be de-energized thus de-energizing the burner. The flame safeguard would

then be on safety lockout and would require manual resetting. The heat alarm relay (R24) would then

be energized and would then energize the remote HEAT FAIL indicator light and send a fail signal to

the MicroTech input board (ADI).

If an attempt is made to restart the burner by resetting the flame safeguard after a flame failure or

anytime an automatic restart is initiated, the earlier described prepurge cycle with the wide open air

valve will be repeated.

If the unit overheats, the combination fan–high limit control (FLC) will cycle the burner limiting

furnace temperature to the limit control set point.

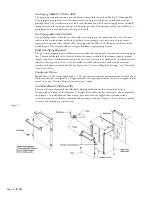

Figure 6b. Typical Piping Schematic