Installation (Continued)

forth to verify end play exists. If

detectable end play completely

disappears before capscrews are

completely tight (torqued to 10 ft.

lbs.), disassemble and remove

sufficient shims until, with

capscrews fully tightened, shaft

end play is barely detectable

(0.001 to 0.004).

2. When sliding a shaft seal over a

shaft extension, all sharp edges

(keyways, etc.) must be protected

with tape to prevent lips of oil seal

from being damaged.

3. When replacing seals, they must be

pressed squarely into the bore, to

prevent distortion and damage.

a.Press on metal retainer only. Lips

should be towards the inside of

unit.

b.The oil seal in the bearing cap

assembly (Ref. Figure 5 No. 9) is

preassembled in the cap. Use

bearing grease to coat seal surface

on shaft for initial run and pack

same grease between lips on seal

and on side of seal towards inside

of unit.

4. If unit has been disassembled, new

gaskets may be required to prevent

lubricant leakage. Both bearing cap

and housing cover are assembled

with a gasket. Gaskets should have

shellac on one side only, due to

possible repeated disassemblies to

achieve the proper output shaft end

play.

5. If unit has been disassembled and no

parts including the gasket (Ref.

Figure 5 No. 18) have been replaced,

no change in the shim stack (Ref.

Figure 5 No. 17) should be required

unless due to wear on parts. (Check

end play before disassembly).

6. When replacing bearings, care

should be exercised that new

bearings are pressed on straight and

properly seated against the shaft

shoulder or bore recess. For bearings

on shafts, press on inner race only.

Cleaning

Properly selected and installed electric

motors are capable of operating for

long periods with minimal

maintenance. Periodically clean dirt

accumulations from open-type motors,

especially in and around

vent openings, preferably by

vacuuming (avoids imbedding dirt in

windings). At the same time, check that

electrical connections are tight.

Lubrication

The Speed Reducer has been filled with

oil at the factory. After the initial 100

hours of operation, original oil should

be drained and unit refilled with new

lubricant. Thereafter, drain and refill

every 6 to 8 months or 2000 hours of

operation, whichever occurs sooner.

Lubricant should be changed more

frequently for severe operating

conditions. Refer to chart for proper

classification of lubricant to be used at

any given air temperature. Fill to level

shown in Figure 3, depending on

orientation.

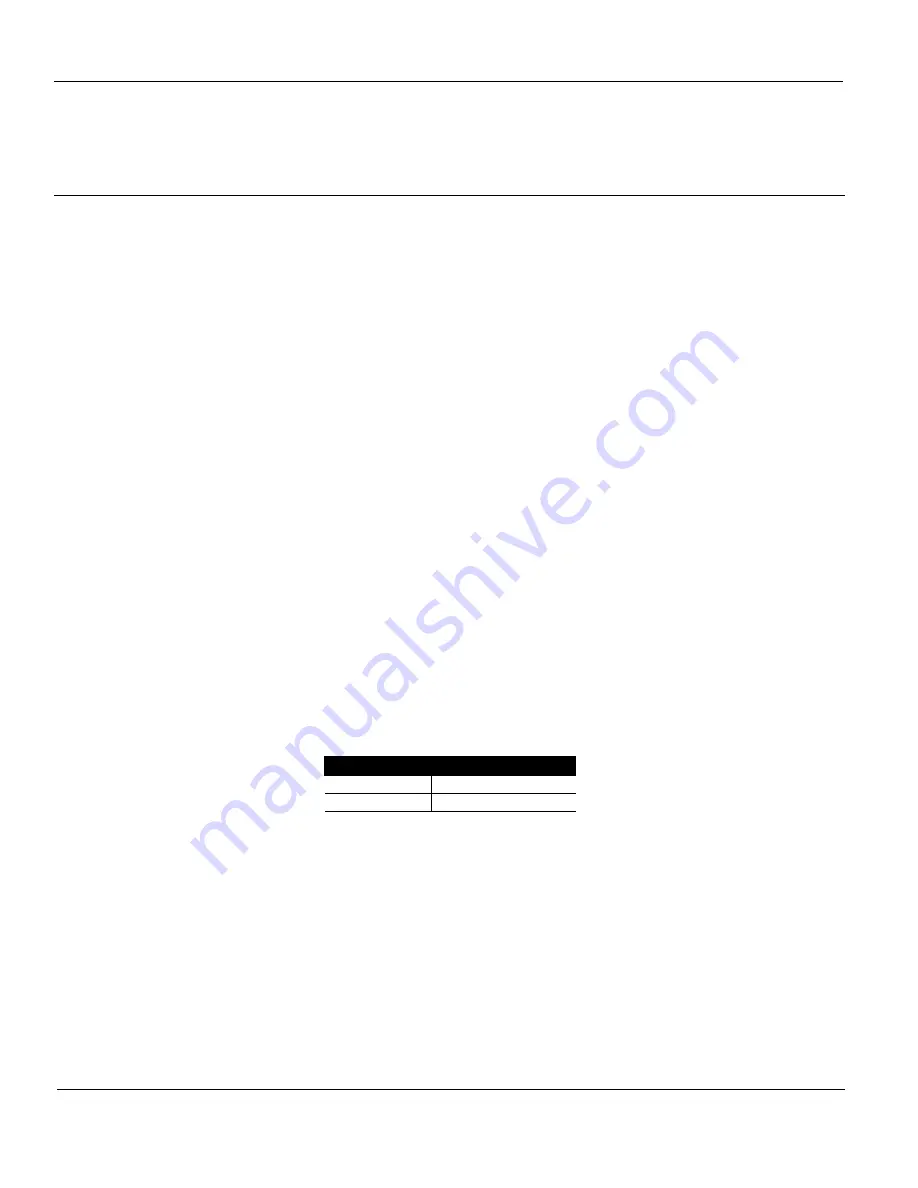

Recommended Worm Gear

Oil AGMA† Classification

Air Temp. ºF

AGMA Lubricant No

15-50

7EP

50-125

8EP

(†) American Gear Manufacturer’s

Assoc.

4

Dayton Operating Instructions and Parts Manual

Dayton

®

Speed Reducers

2Z306F thru 2Z310F

21

Содержание Magic Finger Bagger

Страница 14: ...14...

Страница 15: ...15...

Страница 16: ...16...

Страница 17: ...17...

Страница 36: ...Integral Horsepower DC Motor Installation Operating Manual 5 05 MN605 36...

Страница 48: ...Section 1 General Information 2 6 Installation Operation MN605 48...

Страница 66: ...66...

Страница 67: ...67...

Страница 68: ...68...

Страница 69: ...69...

Страница 70: ...70...

Страница 71: ...71...

Страница 72: ...72...

Страница 73: ...73...

Страница 74: ...74...

Страница 75: ...75...

Страница 76: ...76...

Страница 81: ...81...

Страница 84: ...DECAL REORDER SHEET DECAL NUMBER DECAL IDENTIFICATION D001 D002 D003 D004 D005 84...

Страница 85: ...DECAL REORDER SHEET DECAL NUMBER DECAL IDENTIFICATION D006 D007 D008 D009 85...