31

ITALIANO

ENGLISH

SUOMI

raggiungere la velocità della P.T.O. (540 giri/min.).

È assolutamente sconsigliabile superare i giri sopra indicati

in quanto la macchina è stata dimensionata per funzionare a

quelle velocità avendo in tal modo il massimo rendimento della

stessa.

- Innestare la marcia a cominciare la lavorazione.

- Se necessario regolare con il sollevatore l’altezza di lavoro, evitando

che gli organi di taglio (coltelli o mazza) vadano a contatto con il

terreno (Fig. 38).

- Se necessario regolare la velocità del trattore.

- Regolando la posizione del rullo si aumenta o si diminuisce l’altezza

di taglio rispetto al terreno (altezza min. 3 cm, Fig. 38).

Velocità di avanzamento

- Occorre tenere presente che bisogna regolare la velocità di avan-

zamento del trattore al tipo e alla quantità di materiale da trinciare in

quanto una

velocità eccessiva

danneggia gli organi di trasmissione,

logorandoli anzitempo.

In tal caso si avrà un triturato scadente con possibile espulsione di

materiale grossolano che per la maggiore inerzia può superare i limiti

di sicurezza previsti.

CAUTELA

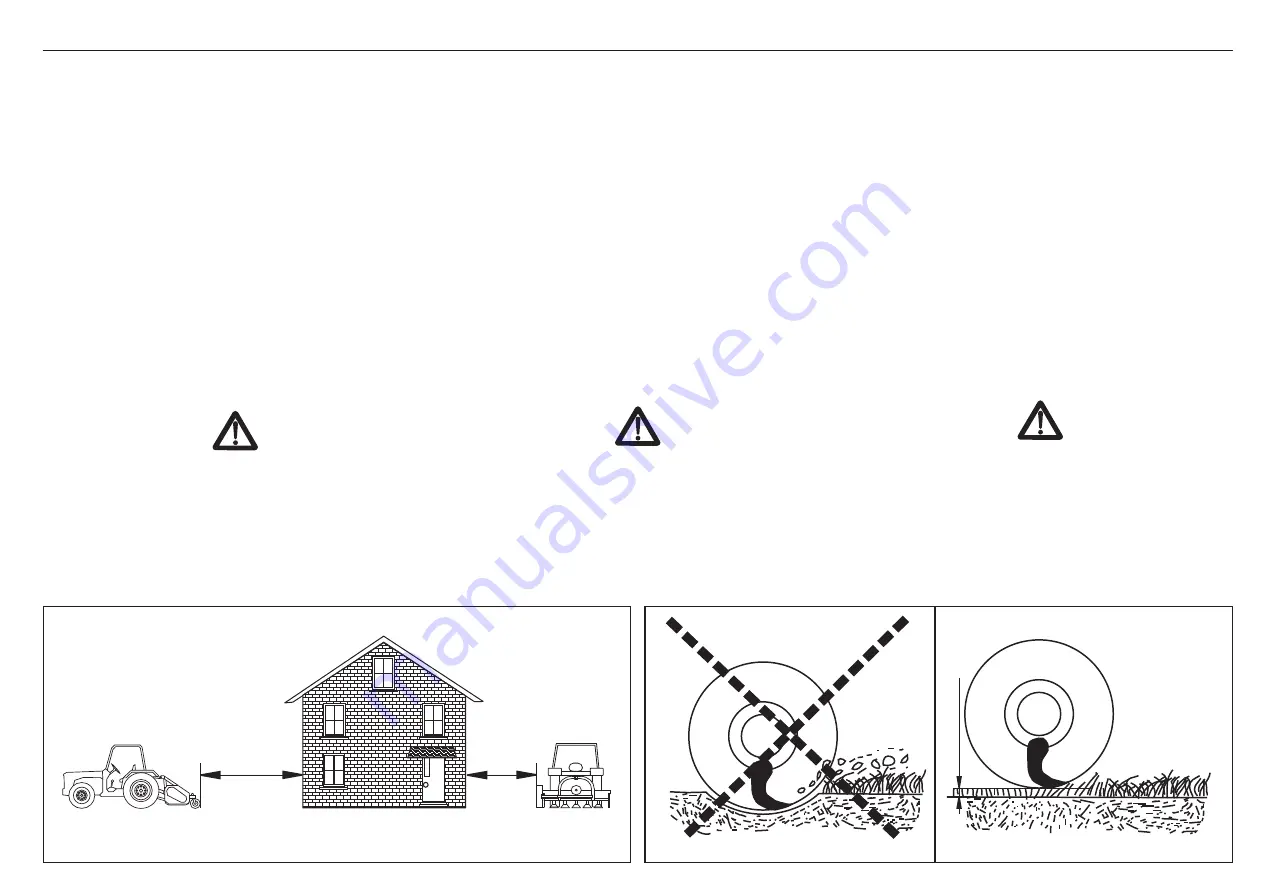

La velocità del trattore con la macchina in lavoro non deve supera-

re i 10 Km/ora al

fi

ne di evitare rotture o danneggiamenti (Fig. 39).

the PTO is spinning at the required speed (540).

It is highly inadvisable to exceed this rate as the machine has

been sized to provide its utmost ef

fi

ciency at these speeds.

- Engage the gear and begin to work.

- Adjust the work height with the power lift controls if necessary.

Remember that the cutting tools (knives or hammers) must not touch

the ground (Fig. 38).

- Modify the speed of the tractor if necessary.

- Adjust the position of the roller to raise or lower the cutting height

from the ground (min. height 3 cm, Fig. 38).

Ground speed

- Remember that the tractor’s ground speed must be regulated to suit

the type and quantity of material being cut as an

excessive speed

will damage the transmission components and make them quickly

wear out.

This will result in a poor quality cut while coarse material could be

thrown up having overcome the envisaged safety limits owing to

greater inertia.

CAUTION

The speed of the tractor with the machine working must not ex-

ceed 10 Km/hr in order to avoid breakage or damages (Fig. 39).

peutta, kunnes se saavuttaa voimanoton 540 vastaavan kierrosno-

peuden.

Voimanoton kierrosnopeutta ei saa ylittää, sillä kone on suun-

niteltu niin, että sen teho on paras mahdollinen tällä nopeu-

della

- Kytke ajovaihde ja aloita työ.

- Säädä sängen pituus tarvittaessa nostolaitteen avulla.

Muista, että terät eivät saa koskettaa maata (kuva 38).

- Muuta tarvittaessa traktorin ajonopeutta.

- Säädä tarvittaessa kannatintelan korkeutta sängen pituuden säätä-

miseksi (vähimm.pituus 3 cm, kuva 38).

Ajonopeus

- Muista, että traktorin ajonopeus on säädettävä olosuhteiden ja

kasvuston mukaan, sillä liian suuri nopeus vaurioittaa voimansiirron

komponentteja.

Lisäksi se heikentää murskaustulosta, sillä karkea materiaali voi jäädä

osittain murskaamatta.

VAROITUS

Ajonopeus ei koneen käytön aikana saa ylittää 10 km/h rikkoutu-

misien ja vaurioiden välttämiseksi (kuva 39).

10 m

5 m

Fig. 37

OK

Fig. 38

Min. 3 cm

Содержание GIRAFFA 160

Страница 43: ...43 ITALIANO ENGLISH SUOMI...