Installation manual - Ecotype - 25

•

Act alternatively on one support and on the other one, tightening up the cable in the same way on both sides.

•

When the required tension is achieved, block the guide pulley tightening the central screw (

3

)

WARNING!

During the installing activities of the steel cable the use of suitable protective gloves is mandatory in

order to avoid any injury to hands due to a possible fraying of the steel cable mesh.

IMPORTANT!

Once terminated this operation

make sure that the bow is perpendicular to the side board and at

equal distance from the tailgate

. If not, operate consequently on the tensioning device of the steel

cable or, if necessary, proceed to block it.

HAND OPERATED VERSION for tipper body length > 8 m

and ELECTRIC VERSION

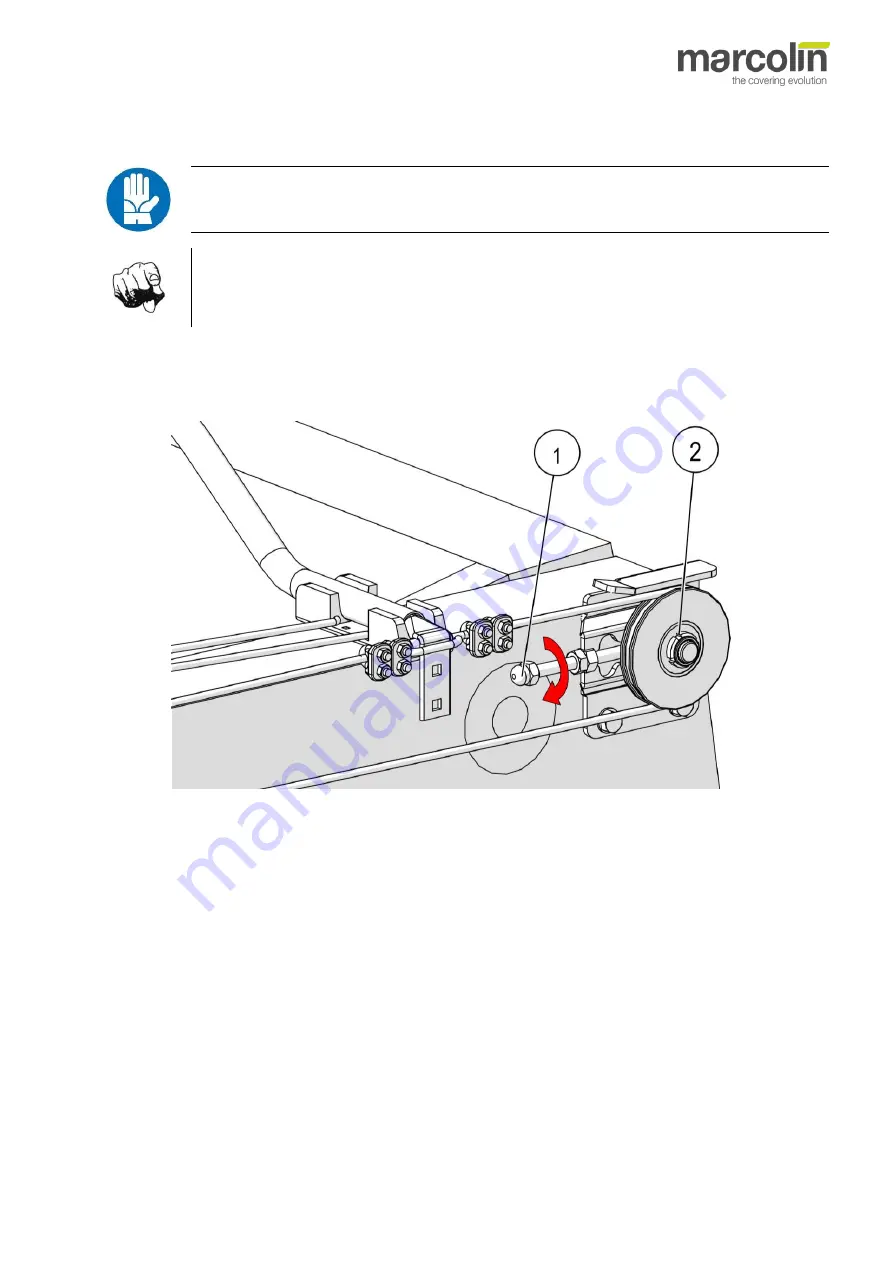

To do this you need to act on two front supports. In fact, the anterior drive pulleys have been developed and manufactured in

order to allow the operator to adjust the steel cable tension.

Operating alternately on the two rear tensioning plates proceed as follows:

•

Use a 10 Nm torque wrench to tighten the screw placed on the front side (

1

) of the drive pulley. As a consequence, the

drive pulleys move backwards, in this way tightening up the steel cable.

•

When the required tension is achieved, block the guide pulley tightening the central screw (

2

)

•

Act alternatively on one support and on the other one, tightening up the cable in the same way on both sides.